Silicon carbide epitaxial growth device

An epitaxial growth, silicon carbide technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of uneven temperature on the gas outlet side, poor gas uniformity, thermal deformation of the spray device, etc., to avoid turbulent flow , temperature uniformity, the effect of improving doping uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present application and not limit the scope of the present application. The implementation conditions adopted in the examples can be further adjusted as the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

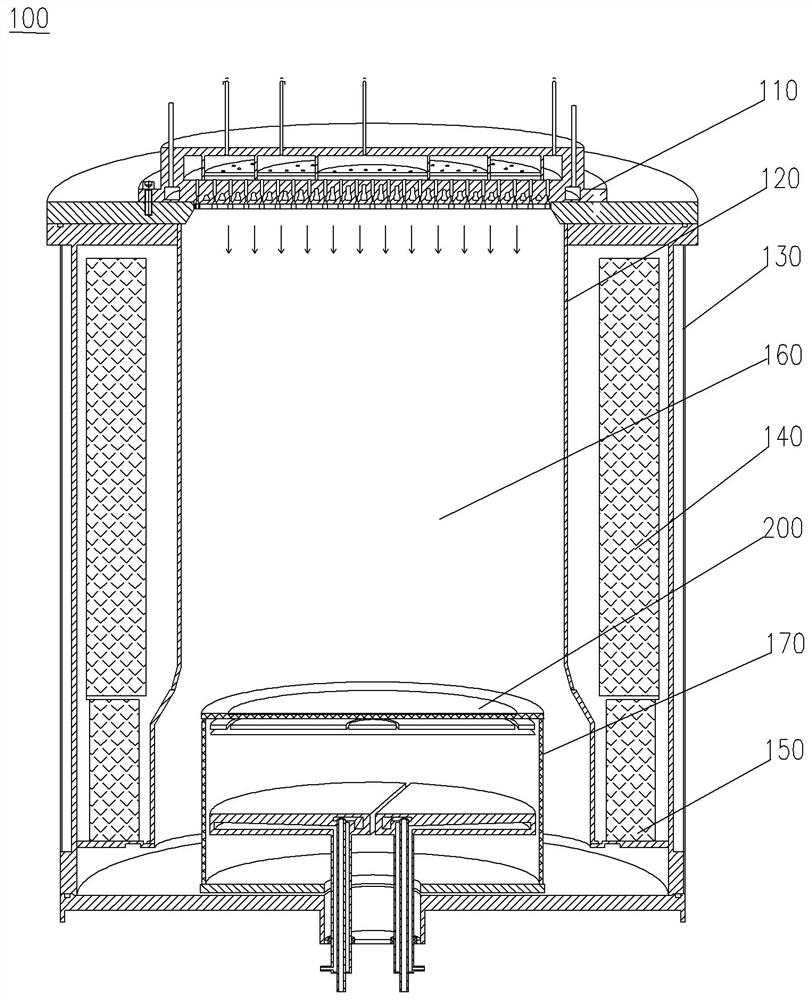

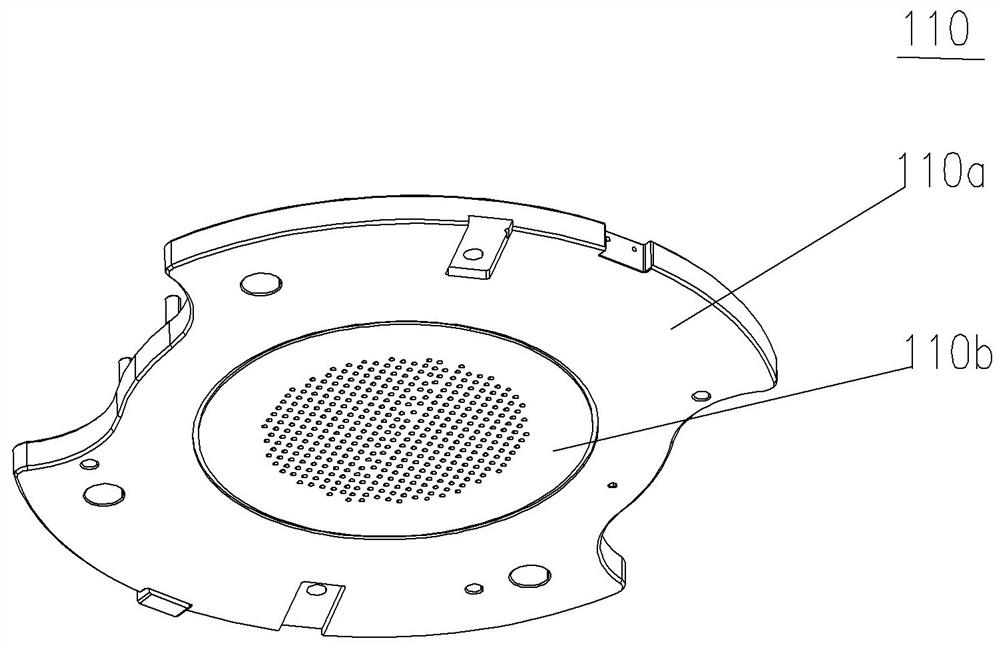

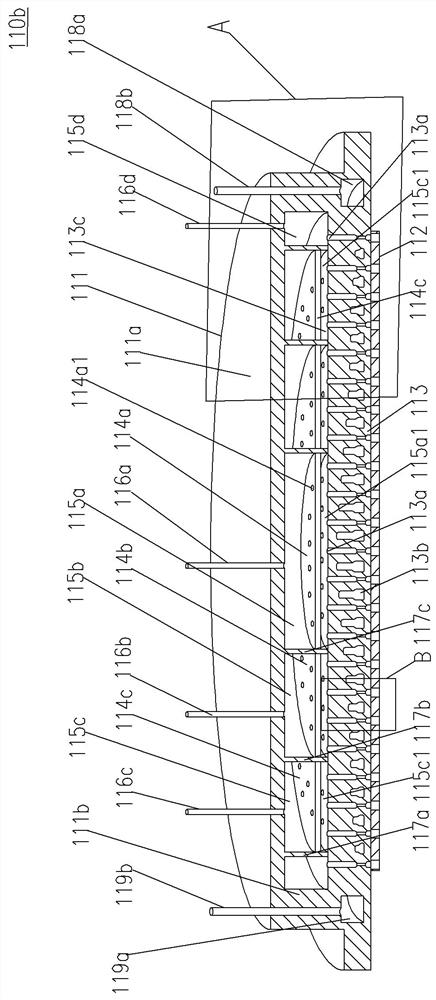

[0036] The present application proposes a silicon carbide epitaxial growth device. The silicon carbide epitaxial growth device includes: a reaction module, which is equipped with a reaction chamber; a shower assembly, which is arranged on the reaction module, and the shower assembly includes: a shower, and the shower includes: a plurality of independent Cavities, a plurality of the cavities are respectively connected to the gas source used to provide gas through pipelines and respectively communicated with the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com