A light-weight vibration-isolating metal composite flywheel bracket and its preparation method and application

A metal composite and flywheel technology, applied in vibration suppression adjustment, mechanical equipment, additive manufacturing, etc., can solve problems such as poor applicability and difficult performance, and achieve the effect of reducing weight, excellent performance, and increasing vibration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

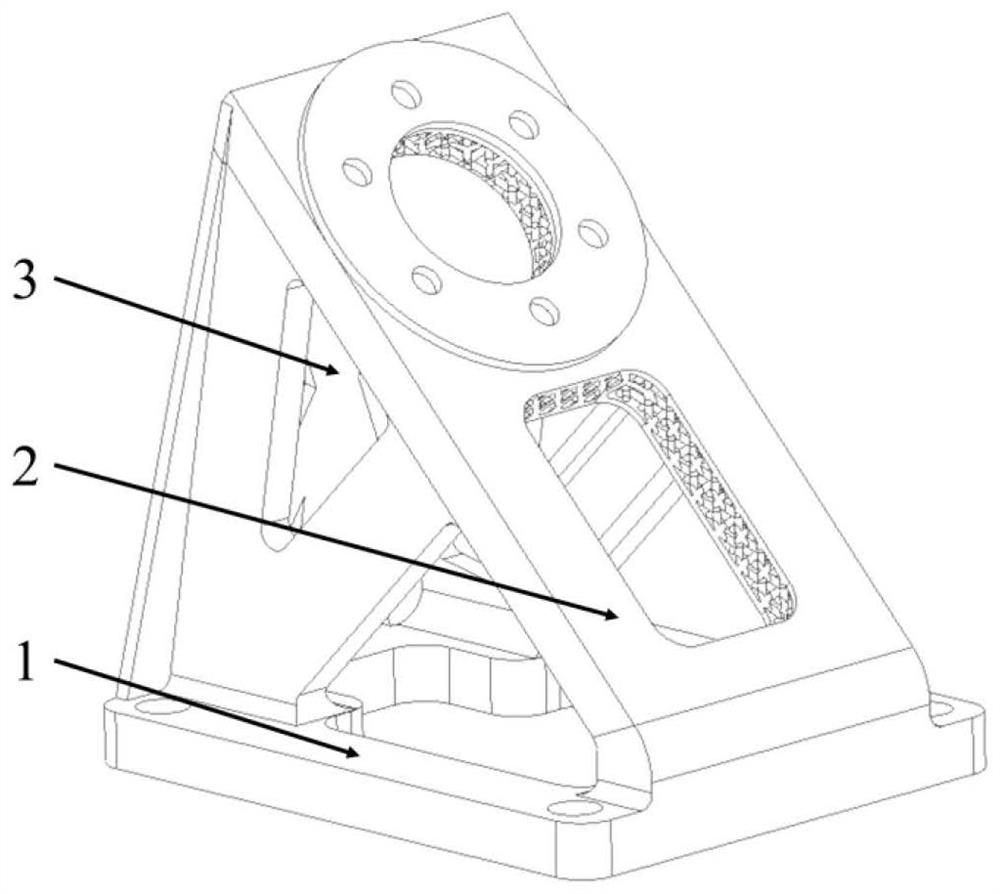

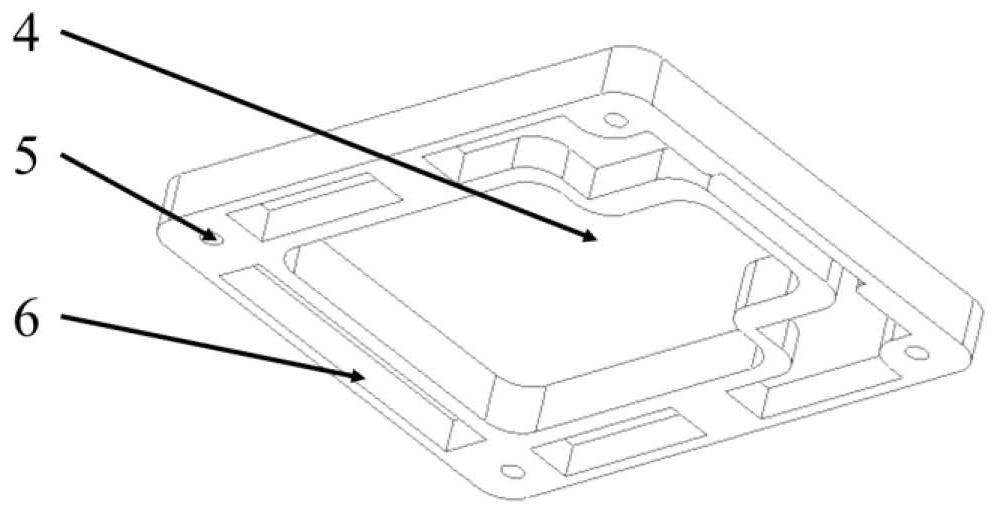

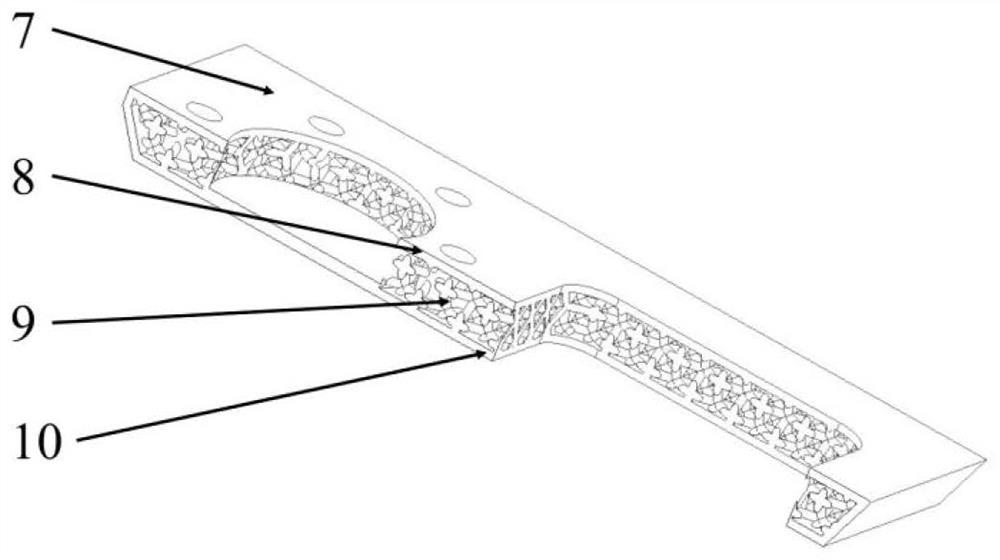

[0044] The material of the base plate 1 of the lightweight vibration-isolating magnesium-zirconium alloy and TC4 titanium alloy composite flywheel bracket is magnesium-zirconium alloy, and its edges have 4 mounting holes 5 and 4 weight-reducing grooves 6; the material of the flywheel mounting surface 2 is TC4 For the titanium alloy, the thickness of the outer wall plate 8 is 1 mm, the thickness of the inner wall plate 9 is 0.5 mm, and the thickness of the lattice layer 10 is 5 mm. The material of the support beam 3 is TC4 titanium alloy, the wall thickness of the ordinary beam 11 is 4mm and the width is 20mm, the thickness of the side wing reinforcement rib 12 is 4mm and the maximum width is 5mm, and the width of the inclined beam of the m-shaped reinforcement beam 13 is 5mm, thickness 2mm, vertical beam width 15mm, thickness 5mm. The magnesium-zirconium alloy plate is machined into the base plate 1, and the three-dimensional model of the flywheel mounting surface 2 and the su...

Embodiment 2

[0046] The material of the base plate 1 of the lightweight vibration-isolating magnesium-nickel alloy and TB6 titanium alloy composite flywheel bracket is magnesium-nickel alloy, and its edge has 6 mounting holes 5 and 8 weight-reducing grooves 6; the material of the flywheel mounting surface 2 is For the TB6 titanium alloy, the thickness of the outer wall plate 8 is 3 mm, the thickness of the inner wall plate 9 is 1 mm, and the thickness of the lattice layer 10 is 10 mm. The material of the support beam 3 is TB6 titanium alloy, the wall thickness of the ordinary beam 11 is 8mm and the width is 35mm, the thickness of the side wing reinforcement rib 12 is 6mm and the maximum width is 10mm, and the width of the inclined beam of the m-shaped reinforcement beam 13 is 10mm, thickness 5mm, vertical beam width 15mm, thickness 10mm. Machining the magnesium-nickel alloy plate into the bottom plate 1, constructing the three-dimensional model of the flywheel mounting surface 2 and the su...

Embodiment 3

[0048] The material of the base plate 1 of the lightweight vibration-isolated AZ31 magnesium alloy and titanium-aluminum alloy composite flywheel bracket is AZ31 magnesium alloy, and its edges have 4 mounting holes 5 and 4 weight-reducing grooves 6; the material of the flywheel mounting surface 2 is For titanium aluminum alloy, the thickness of the outer wall plate 8 is 2 mm, the thickness of the inner wall plate 9 is 2 mm, and the thickness of the lattice layer 10 is 11 mm. The material of the support beam 3 is titanium-aluminum alloy, the wall thickness of the ordinary beam 11 is 5mm and the width is 30mm, the thickness of the flank reinforcing rib 12 is 5mm and the maximum width is 13mm, and the width of the inclined beam of the m-shaped reinforcing beam 13 is 13mm, thickness 5mm, vertical beam width 15mm, thickness 6mm. The AZ31 magnesium alloy plate was machined into the bottom plate 1, the three-dimensional model of the flywheel mounting surface 2 and the support beam 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com