Cloud intelligent automobile power assembly test system and method

An automotive powertrain and test system technology, applied in vehicle testing, signal transmission system, machine/structural component testing, etc., can solve problems such as large workload, lack of remote operation means for researchers, and low system integration , to achieve the effect of convenient operation, improve the experimental environment, and improve the experimental efficiency

Pending Publication Date: 2022-02-18

上海智能网联汽车技术中心有限公司 +1

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional automotive powertrain test system only includes three parts: automotive powertrain, load dynamometer, and industrial computer. It has a low degree of automation and a single function. Individual testing of the transmission or vehicle power source

At the same time, the huge workload also puts forward high requirements on the operational skills of the researchers, which has a negative impact on the working environment of the researchers

[0003] The existing technical solutions propose an improved vehicle powertrain test system from different perspectives, including starting from multi-functionality, by adding a comprehensive experiment management module, a human-vehicle-road simulation module, an experimental data management module and a remote information service module , a multi-objective, multi-category testing system is proposed, which can perform automated testing, calibration, and evaluation experiments. The system integration level is low, and the system is too responsible; a vehicle dynamics test method and system based on an unattended system is proposed for rail vehicles, and a data transmission network is built with a cloud server as the core, allowing researchers to remotely control the test system, but this solution is aimed at rail vehicles, and its degree of freedom of testing does not meet the test requirements of non-rail vehicles, and the hardware improvement of the test system is insufficient to meet the multi-case and multi-category test requirements; for pure electric vehicles or For the motor part of hybrid electric vehicles, a powertrain test system is designed to test the battery motor system, which can test the battery motor system under different temperature and humidity conditions. There are many test scenarios, but there is also a lack of remote operation methods for researchers.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

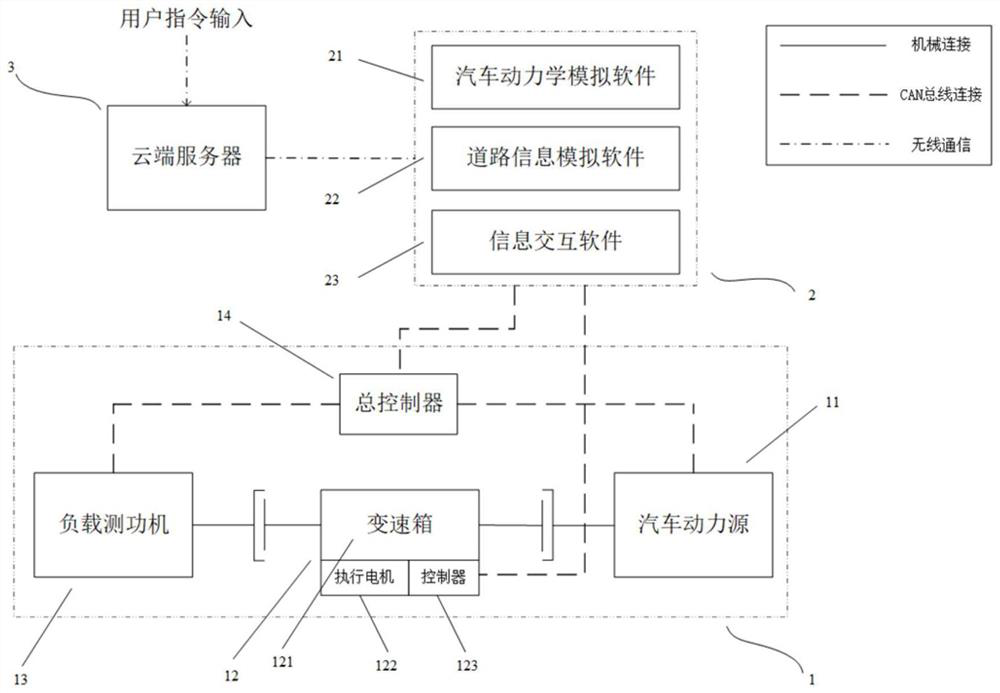

[0040] like figure 1 As shown, the present invention provides a cloud intelligent vehicle powertrain testing system, which includes a powertrain test bench 1, a computer software platform 2 and a cloud server 3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a cloud intelligent automobile power assembly test system. The system comprises a cloud server which is in wireless communication connection with a computer software platform through a network interface; a computer software platform, comprising automobile dynamics simulation software, road information simulation software and information interaction software, and the computer software platform being connected with the master controller and the execution motor controller through CAN buses; a power assembly test bench, comprising an automobile power source, an integrated gearbox, a load dynamometer and a master controller, the integrated gearbox comprising a gearbox, an execution motor and an execution motor controller, and the integrated gearbox being detachably connected with the automobile power source and the load dynamometer. The master controller is connected with the automobile power source and the load dynamometer through a CAN bus. Compared with the prior art, the system has the advantages that a user can remotely supervise the experiment process and result, the experiment environment of researchers is improved, the experiment efficiency is improved, and the like.

Description

technical field [0001] The invention relates to the technical field of powertrain testing, in particular to a cloud intelligent vehicle powertrain testing system and method. Background technique [0002] With the popularization and development of new energy vehicles, the structure and control strategy of the vehicle powertrain are becoming more and more complex. Correspondingly, the workload of the vehicle powertrain test system is also increasing. The traditional automotive powertrain test system only includes three parts: automotive powertrain, load dynamometer, and industrial computer. It has a low degree of automation and a single function. Separate test for transmission or vehicle power source. At the same time, the huge workload also puts forward high requirements on the operating skills of the researchers, which has a negative impact on the working environment of the researchers. [0003] The existing technical solutions propose an improved vehicle powertrain test s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M17/007G08C17/02

CPCG01M17/007G08C17/02

Inventor 张勇杨小可窦民高瑞金林新雨

Owner 上海智能网联汽车技术中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com