Heat dissipation assembly, compressor and air conditioner

A technology for heat dissipation components and compressors, which is applied to compressors, air conditioning systems, refrigeration components, etc., can solve problems such as overload tripping of fixed-frequency compressor compressors, poor cooling effect of condensers, and air conditioners not working properly, and achieve cost Low cost, stable and reliable heat transfer effect, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

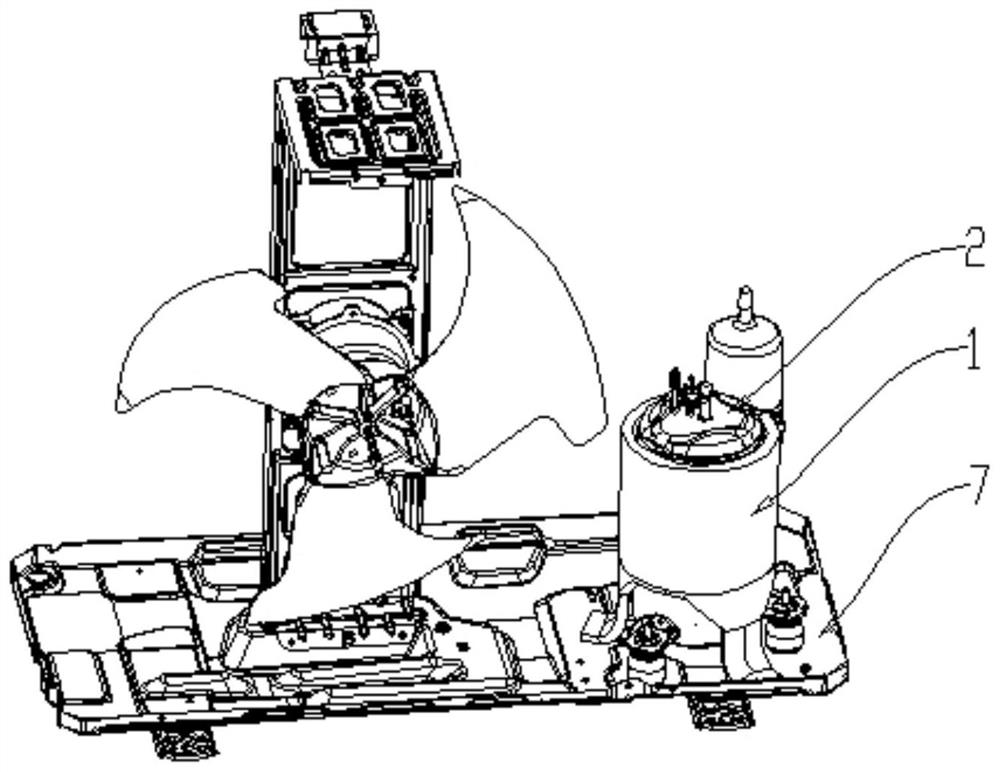

[0037] Such as figure 1 As shown, in view of the fact that the temperature of the cylinder shell is high when the compressor 2 is running, and the chassis 7 has a large area and low temperature, in one embodiment of the present application, a compressor cooling assembly 1 is skillfully proposed. The heat dissipation assembly 1 includes one or more multiple heat dissipation units arranged along the circumference of the compressor 2, and each heat dissipation unit includes:

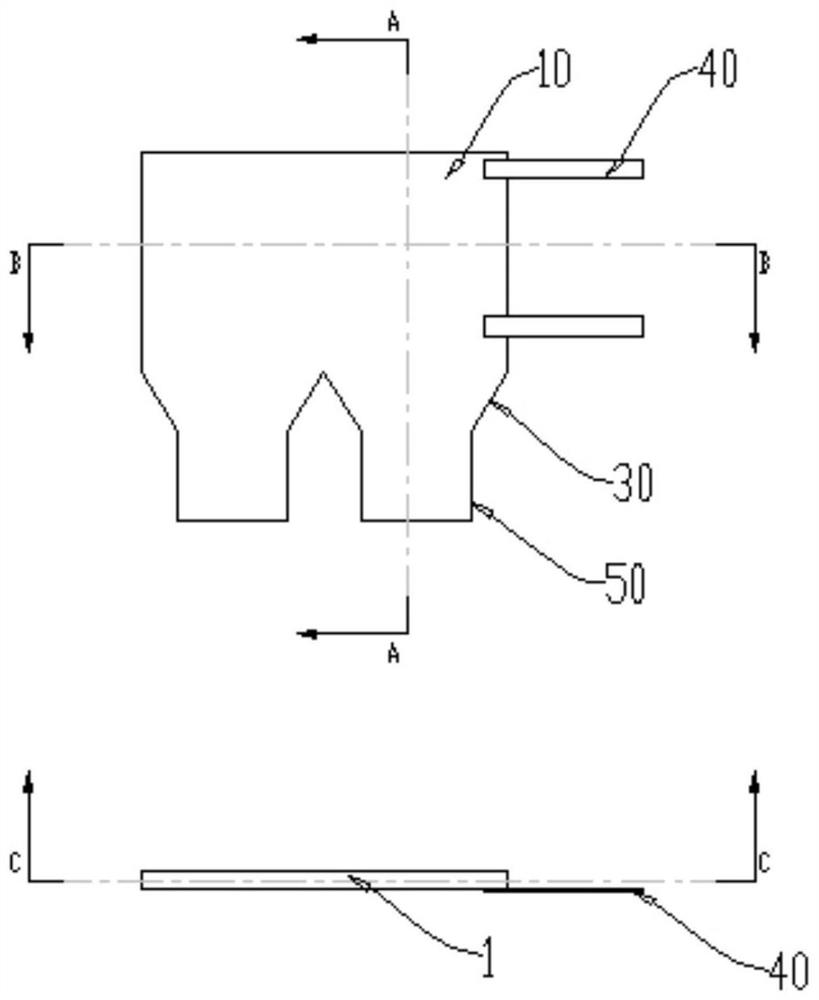

[0038] The bag body 10, the bag body 10 is used to be arranged on the casing of the compressor 2 to absorb the heat emitted by the compressor 2 casing; the bag body 10 is provided with a first cavity;

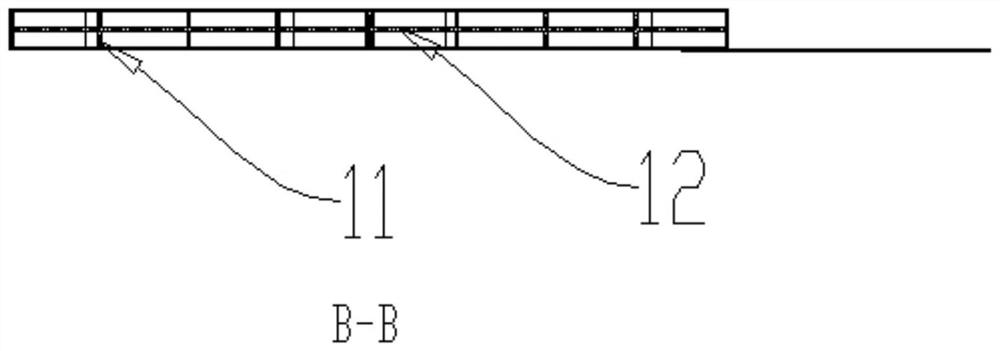

[0039] The middle connecting part 30, the upper end of the middle connecting part 30 is fixedly arranged on the lower end of the bag body 10, the second cavity is arranged in the middle connecting part 30, and the second cavity communicates with the first cavity; the tail part 50, the tail part 50 The upper...

Embodiment 3

[0050] A plurality of heat dissipation units are sequentially connected together along the circumferential direction of the casing to form an annular structure that can be sleeved on the casing of the compressor 2 . The heat dissipation assembly 1 composed of a plurality of heat dissipation units is in contact with the surface of a larger compressor 2 shell, and the heat of the compressor 2 shell is transferred to the heat dissipation assembly 1 to speed up the heat transfer speed.

[0051] Furthermore, a plurality of heat dissipation units are integrally formed or detachably connected together. Multiple heat dissipation units are integrally formed, which can ensure the stability of the overall structure of the heat dissipation unit, play a good supporting role, and reduce the occurrence of cracking due to vibration or thermal expansion and contraction of the compressor 2; multiple heat dissipation units can be detachably connected Together, they can adapt to installation envi...

Embodiment 4

[0054] In one embodiment of the present application, a pump device is disposed in the first cavity of the bag body 10 . Forcing the flow of the heat-conducting liquid to rapidly circulate the heat-conducting liquid among the first cavity, the second cavity and the third cavity can achieve better effects of heat transmission and heat dissipation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com