Automatic analysis and identification device of internal defect in cast and its analysis and identification method

An internal defect, automatic analysis technology, applied in character and pattern recognition, material analysis using radiation, computer parts and other directions, can solve problems such as eye fatigue, low labor intensity, easy fatigue, etc. The cost of the device is low and the labor intensity is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

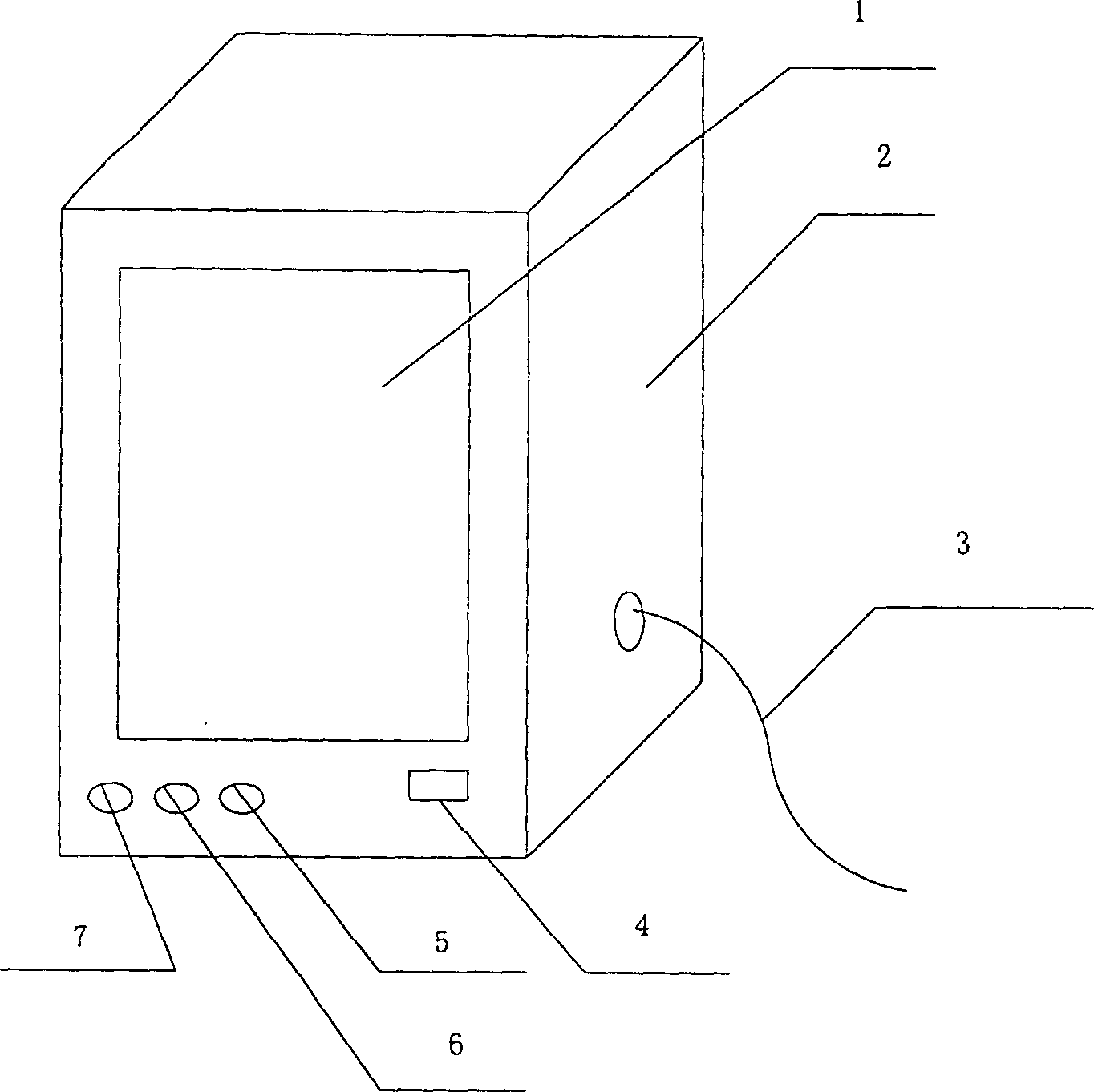

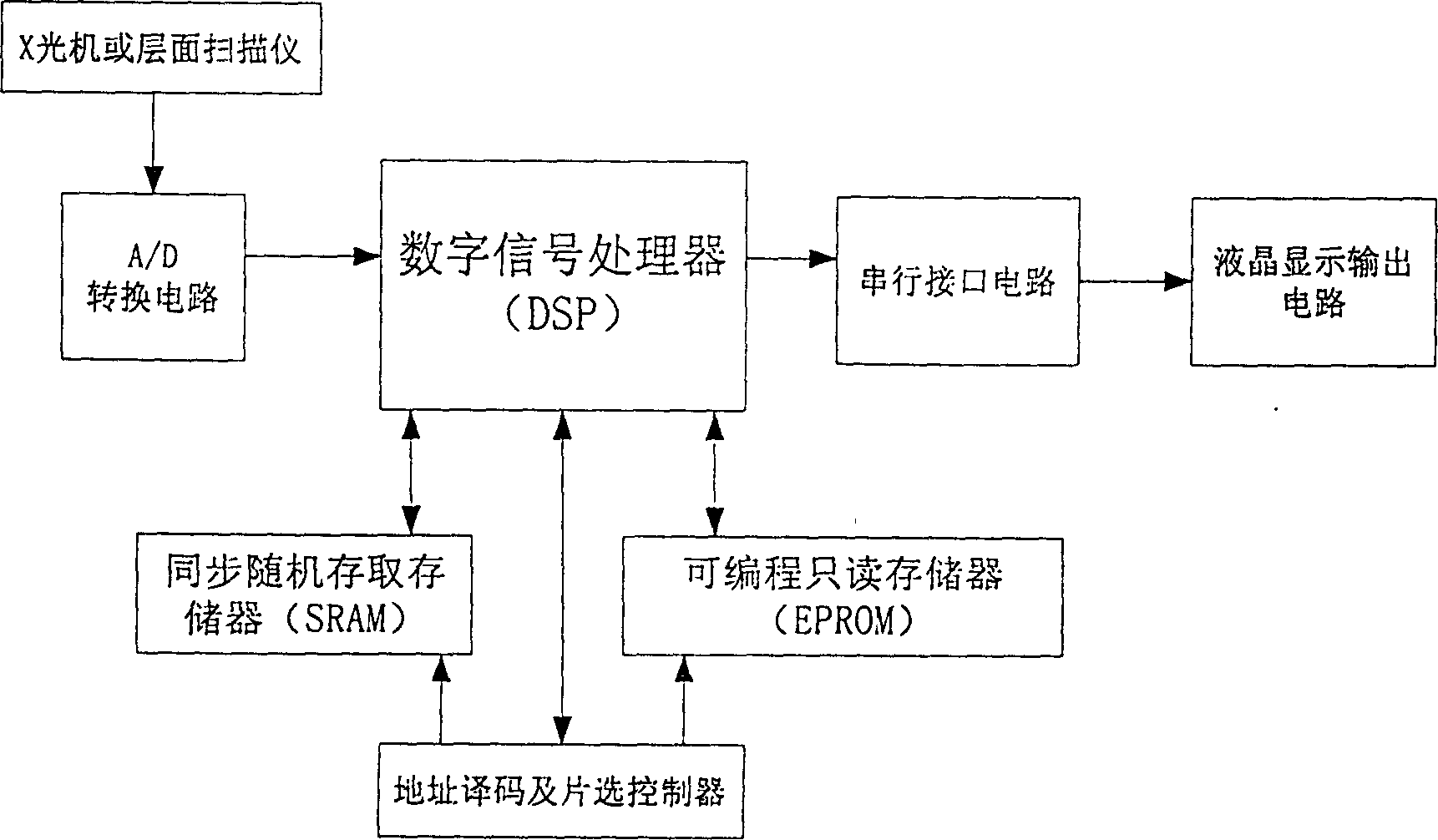

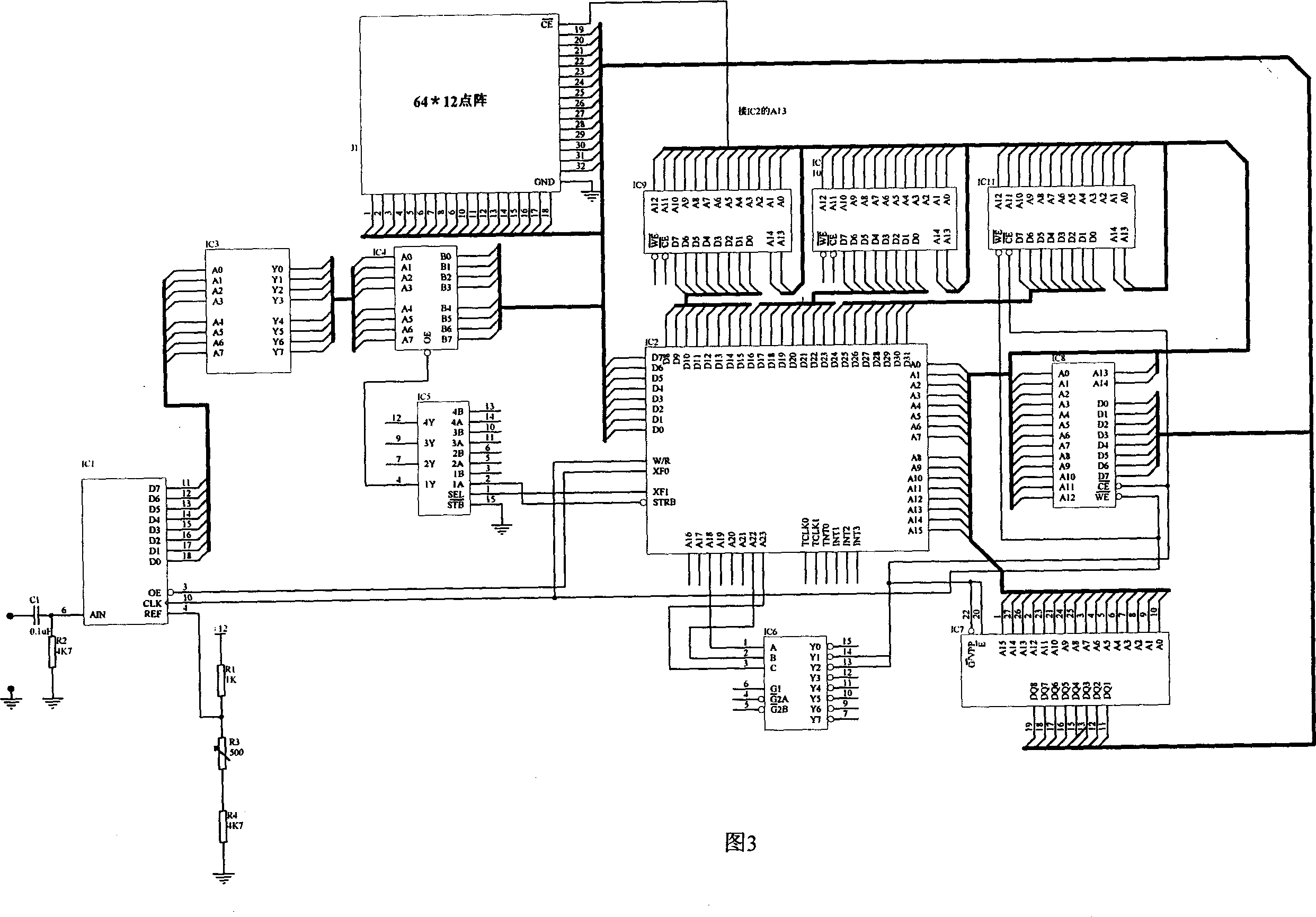

[0008] The casting internal defect automatic analysis and identification device and method thereof of the present invention can be realized by means of software, hardware or a combination of software and hardware, such as writing device processing software with Fortran and C language on a general-purpose computer to realize the method of the present invention, or using a general-purpose Programmable devices such as single-chip microcomputers can be used to replace part of the software functions with hardware, and can also be implemented by using a general-purpose or special-purpose digital signal processor DSP and adding a special-purpose accelerated processor on a general-purpose computer. In the preferred embodiment described now, the method and device for automatic analysis and recognition of casting internal defects are realized by combining software and hardware, and the software flow block diagram is as follows Figure 4 , Figure 5 as shown; (1) press figure 1 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com