Laser tailor-welding method for heterogeneous different-thickness plates

A technology of laser tailor welding and sheet metal, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of mechanical properties, component composition differences, weld joint performance differences, weld joint performance defects, etc., and achieve joint performance Small difference, high welding quality, and the effect of solving poor performance of welded joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

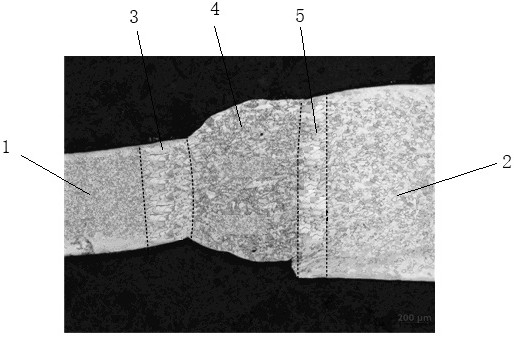

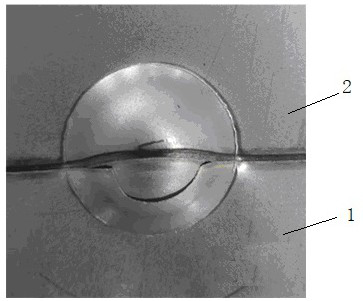

Image

Examples

Embodiment 1-6

[0020] Embodiments 1-6: The laser tailor welding method for plates of heterogeneous and different thickness adopts the following specific processes.

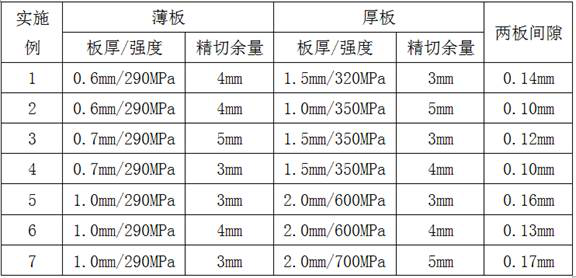

[0021] (1) Prepare two steel plates for automobiles. The thickness and tensile strength of the thick and thin plates are shown in Table 1. Fine-cut the tailor-welded edge, the incision is straight and free of burrs, the fine-cut allowance and the gap between the two plates are shown in Table 1.

[0022] Table 1: Strength grade and thickness of two tailor-welded blanks

[0023]

[0024] (2) Clean the two tailor-welded sheets that have been finely cut. The sheets with better surface cleanliness can be cleaned directly by rollers with felt; if the cleanliness is poor, you need to open the conveyor roller cleaning machine for cleaning .

[0025] (3) Butt the fine-cut edges of two tailor-welded sheets, measure the gap between the butt joints, and ensure that the butt gap is ≤ 10% of the thickness of the tailor-welded side of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap