A method of forming an organic-inorganic hybrid superhydrophobic anti-corrosion coating on the surface of carbon steel

A kind of anti-corrosion coating and super-hydrophobic technology, which can be used in devices that coat liquid on the surface, anti-corrosion coatings, coatings, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

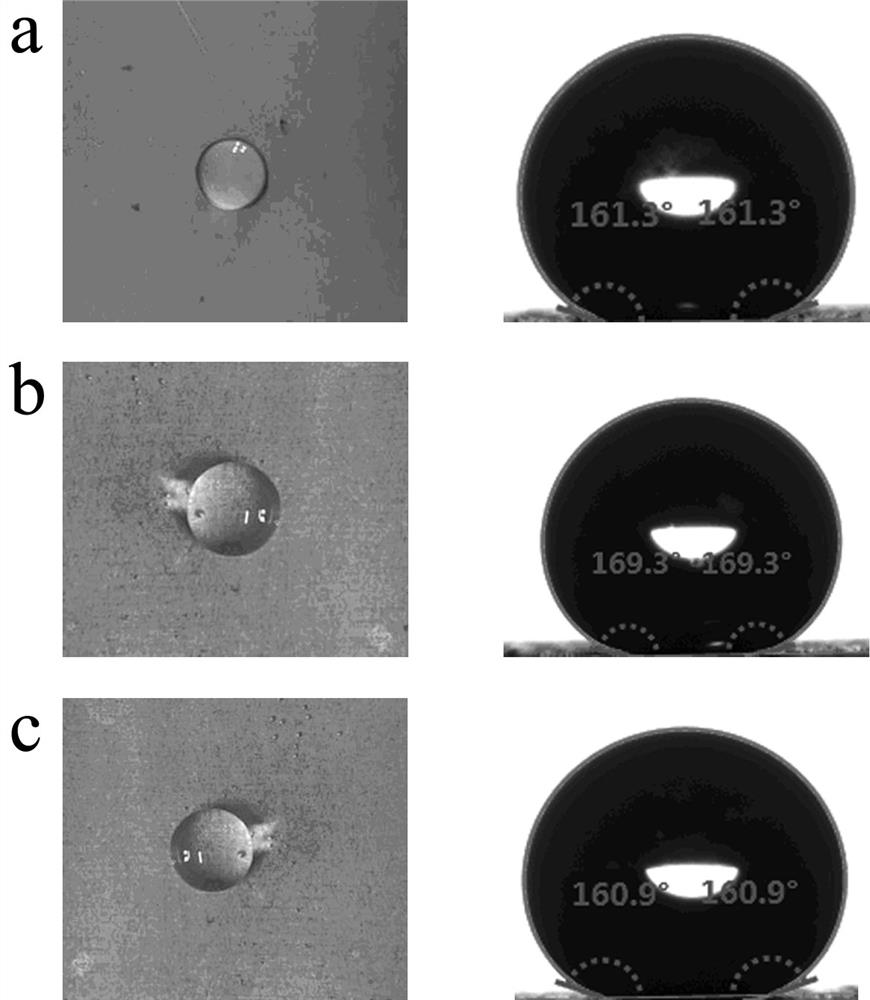

Embodiment 1

[0045] In a 250mL toluene solution containing 5g of silane coupling agent KH550, mCM-41 was added to the mesoporous molecular sieve with an average pore size of 4 nm, heated to 60 °C, magnetically stirred for 3h, filtered, washed, dried, and modified mesoporous molecular sieve was obtained.

[0046] The 3g triazinyl corrosion inhibitor having the following structure was dissolved in 100mL of ethyl acetate, the above-described modified mesoporous molecular sieve was added, impregnated under vacuum for 4h, filtered, washed, dried, and the mesoporous molecular sieve of loading corrosion inhibitor was obtained.

[0047]

[0048] Weigh 10g of epoxy resin, dissolved in 50mL of ethyl acetate, add 0.1g of support corrosion inhibitor mesoporous molecular sieve, 1g of amino silicone oil, 0.1g of sodium dodecyl sulfate and 0.1g of polyethylene glycol 600, first dispersed at a speed of 6000r / min under a high-speed disperser for 20min, and then ultrasonically dispersed for 20min. After the d...

Embodiment 2

[0053] In the 250mL toluene solution containing 7.5g silane coupling agent KH550, 5g of mesoporous molecular sieve MCM-41 with an average pore size of 4 nm was added, heated to 70 °C, magnetic stirring treatment for 4h, filtered, washed, dried, and modified mesoporous molecular sieve was obtained.

[0054] The 3.5g triazinyl corrosion inhibitor having the following structure was dissolved in 100mL of ethyl acetate, the above-mentioned modified mesoporous molecular sieve was added, impregnated under vacuum for 5h, filtered, washed, dried, and the mesoporous molecular sieve of loading corrosion inhibitor was obtained.

[0055]

[0056] Weigh 10g epoxy resin, dissolved in 50mL ethyl acetate, add 0.15g of support corrosion inhibitor mesoporous molecular sieve, 1.5g of amino silicone oil, 0.15g of sodium dodecyl sulfate and 0.15g of polyethylene glycol 600, first dispersed at a speed of 7000r / min under a high-speed disperser for 20min, and then ultrasonically dispersed for 30min. Aft...

Embodiment 3

[0060] In the 250mL toluene solution containing 10g silane coupling agent KH550, 5g of mesoporous molecular sieve MCM-41 with an average pore size of 4nm was added, heated to 80 °C, magnetic stirring treatment for 5h, filtered, washed, dried, and modified mesoporous molecular sieve was obtained.

[0061] 4g of triazinyl corrosion inhibitor having the following structure was dissolved in 100mL of ethyl acetate, the above modified mesoporous molecular sieve was added, impregnated under vacuum for 6h, filtered, washed, dried, and the mesoporous molecular sieve of loading corrosion inhibitor was obtained.

[0062]

[0063] Weigh 10g of epoxy resin, dissolved in 50mL of ethyl acetate, add 0.2g of supported corrosion inhibitor mesoporous molecular sieve, 2g of amino silicone oil, 0.2g of sodium lauryl sulfate and 0.2g of polyethylene glycol 600, first dispersed at a speed of 8000r / min under a high-speed disperser for 20min, and then ultrasonically dispersed for 40min. After the dispersi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com