Supply control system and method for engine oxygen-enriched micro-nano bubble fuel

A micro-nano-bubble and control system technology, which is applied in the direction of engine control, fuel injection control, charging system, etc., can solve the problem of not perfecting the preparation, supply and control system of oxygen-enriched micro-nano-bubble fuel, and achieve high-efficiency and clean combustion , ensure smooth operation, and improve the effect of oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

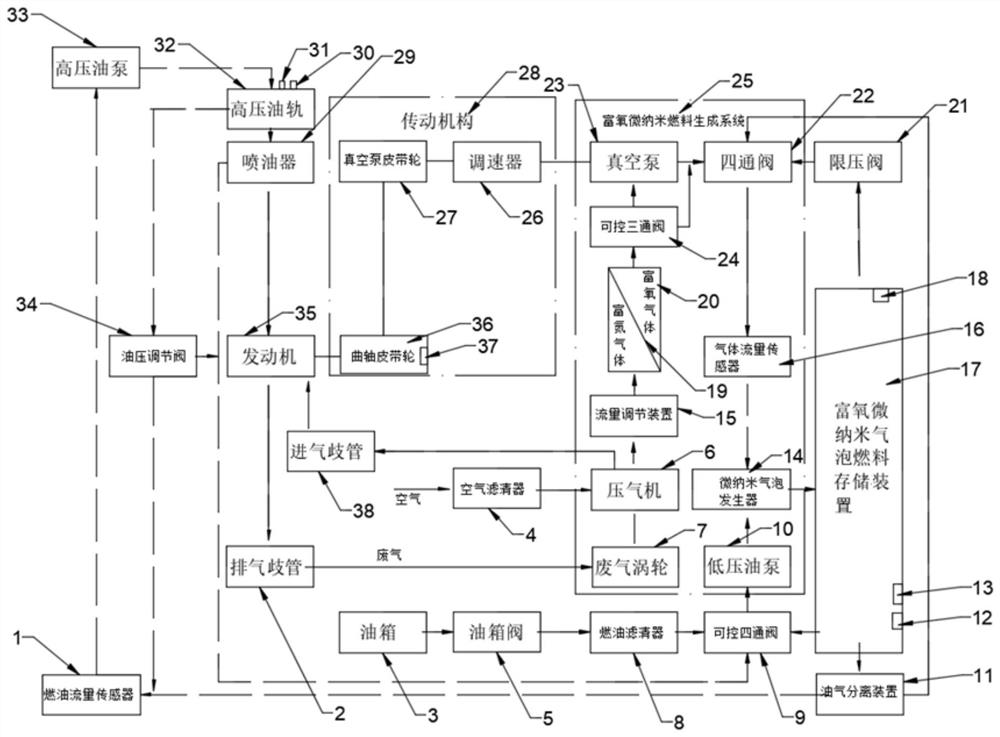

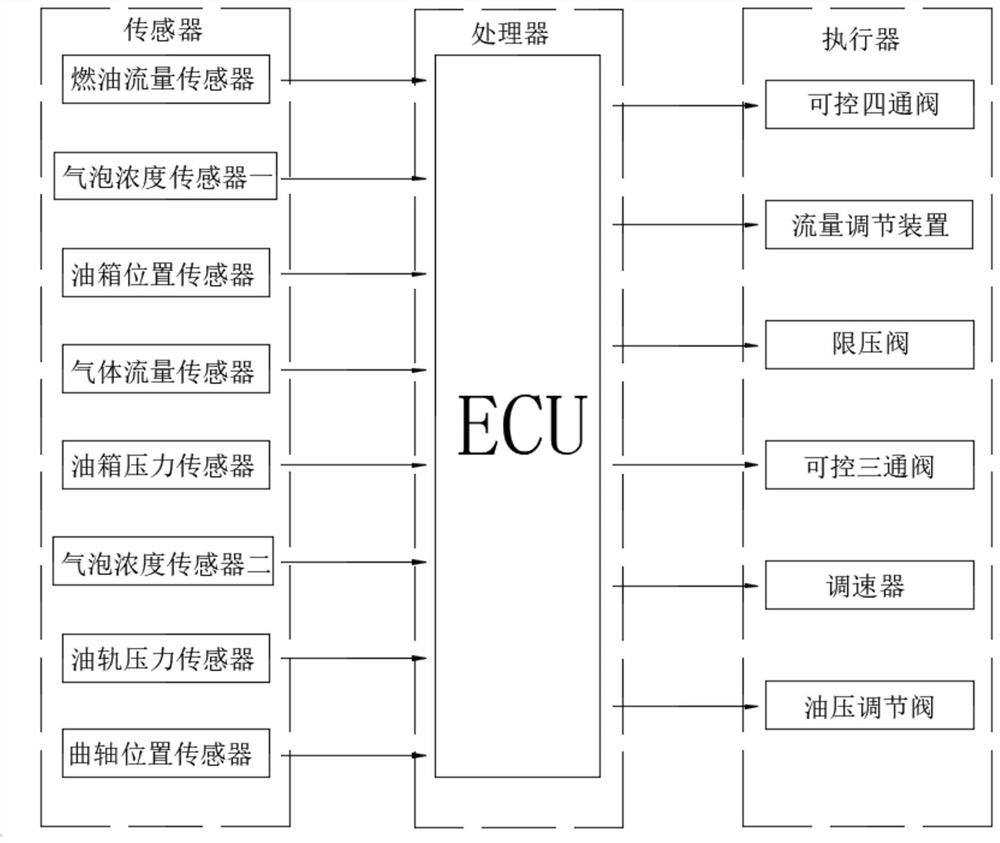

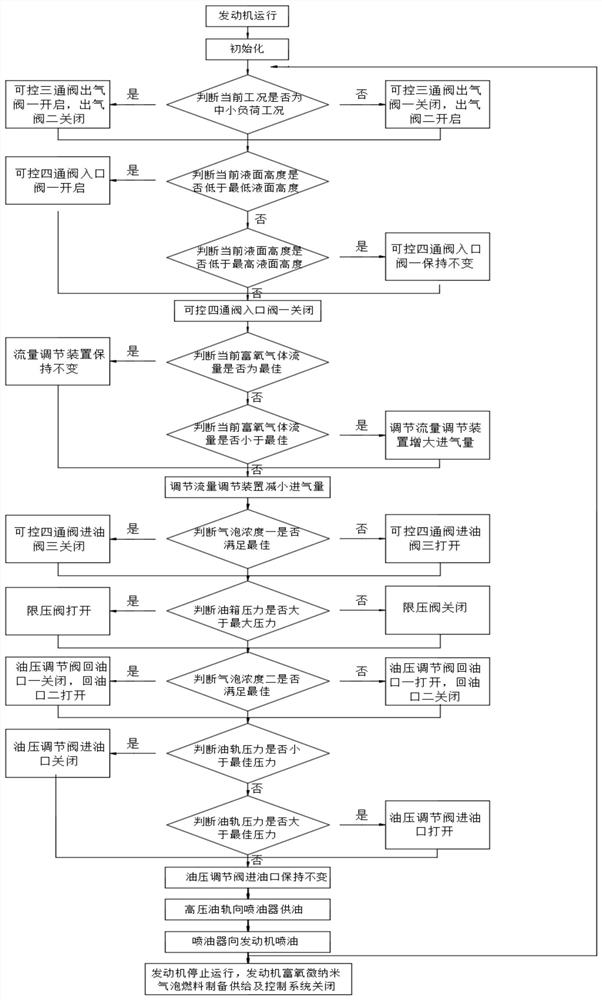

[0040] A supply control system for engine oxygen-enriched micro-nano-bubble fuel, including a fuel tank 3, an air filter 4, a fuel tank valve 5, a fuel filter 8, a controllable four-way valve 9, a transmission mechanism 28, and oxygen-enriched micro-nano fuel Generation system 25, oxygen-enriched micro-nano bubble fuel storage device 17, pressure limiting valve 21, oil-gas separation device 11, fuel flow sensor 1, high-pressure oil pump 33, high-pressure fuel rail 32, fuel injector 29, oil pressure regulating valve 34, ECU 39 , fuel tank pressure sensor 18, fuel tank position sensor 13, bubble concentration sensor one 12, oil rail pressure sensor 31 and bubble concentration sensor two 30, the air becomes oxygen-enriched after being supercharged and filtered in the oxygen-enriched micro-nano fuel generation system 25 body, mixed with fuel in the micro-nano bubble generator 14 to initially form oxygen-enriched micro-nano-bubble fuel, and refined and stored by the oxygen-enriched ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com