Frog-woodpecker combined silicon nitride double-cylinder bionic compressor

A silicon nitride double-cylinder, combined technology, applied in the field of compressor refrigeration, can solve the problem of no change and adjustment of the remaining volume of the compressor shell shape, the improvement of the compressor performance does not play a big role, and the annoying noise of the compressor. And vibration and other problems, to achieve the effect of saving materials, good sound insulation, noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

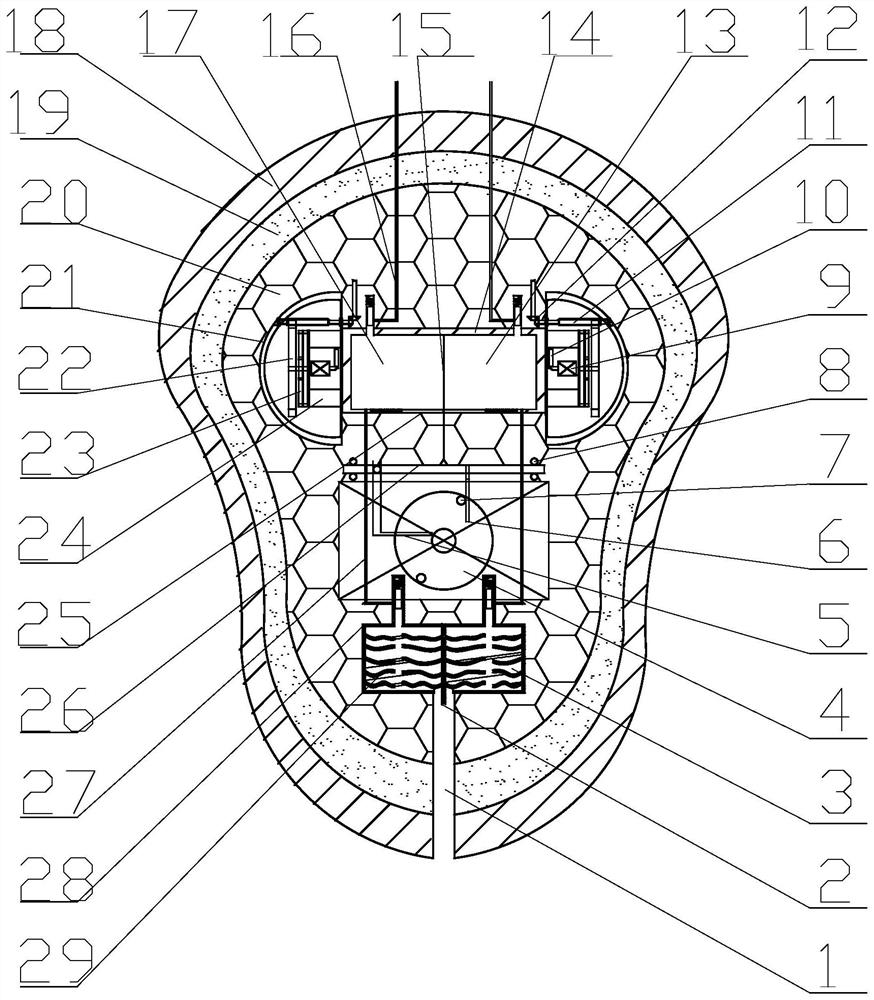

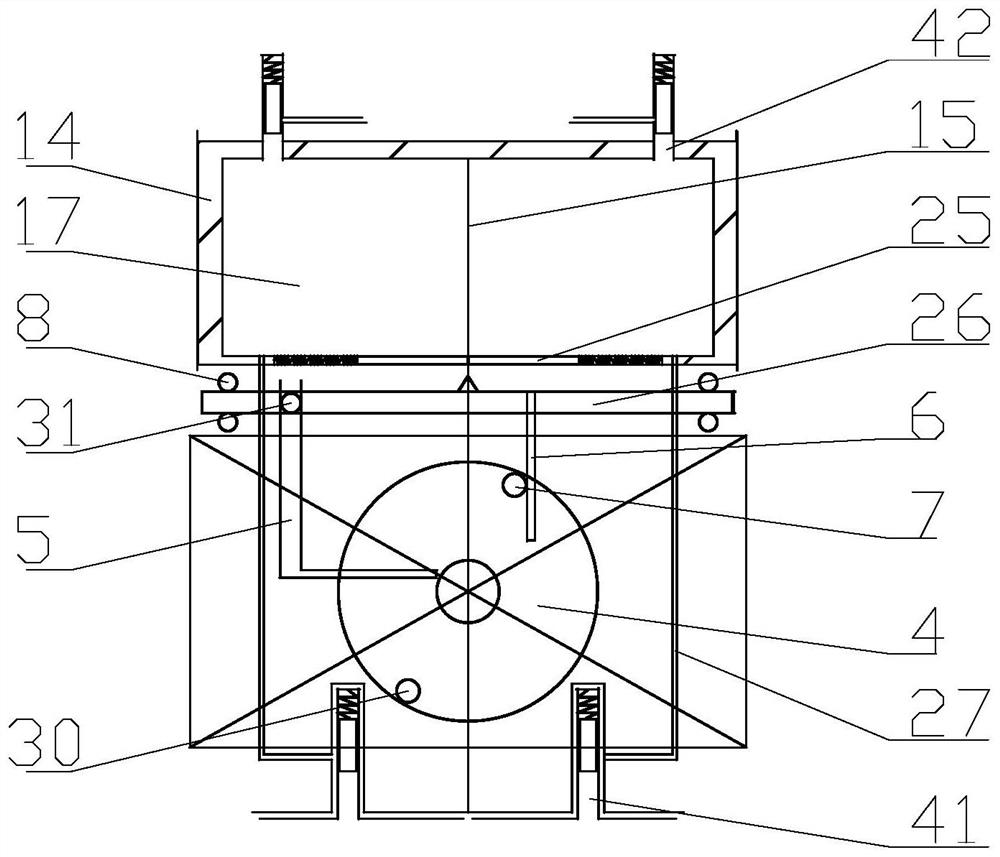

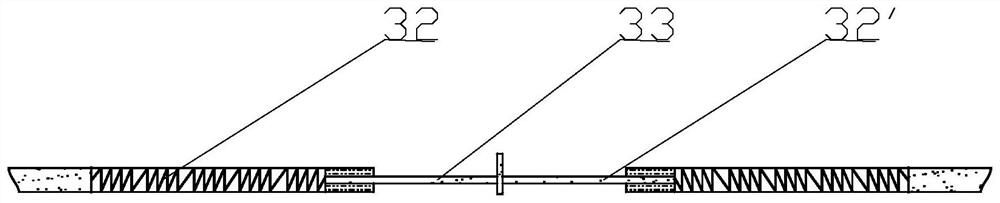

[0039] Figure 1 to Figure 10 Shown is the embodiment of a kind of frog-woodpecker combined silicon nitride double-cylinder biomimetic compressor of the present invention, as figure 1 As shown, it includes a casing, and an intake duct 1 , an intake structure, an exhaust structure, a drive structure, and a cylinder 14 located in the cavity of the casing.

[0040] Such as Figure 10 As shown, the shape of the shell is a frog body shape that the tail portion 38 is large, the middle portion 39 is streamlined, and the head 40 is small. The outer shell has two layers of inner and outer layers, the outer layer 18 is made of stainless steel, and the inner layer 19 is made of silicon nitride; imitating the head structure of a woodpecker, the cavity of the outer shell is filled with an elastic material 20 . Such as figure 1 As shown, the intake duct 1 is longitudinally located at the center of the head 40; the cylinder 14 is cylindrical and placed transversely at the tail 38, and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com