Prestressed concrete cylinder pipe capable of monitoring strain in real time and manufacturing method

A technology of prestressed steel and concrete pipes, which is applied in the direction of manufacturing tools, pipes, rigid pipes, etc., can solve problems such as the inability to realize fully distributed monitoring, and achieve the effect of high applicable value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

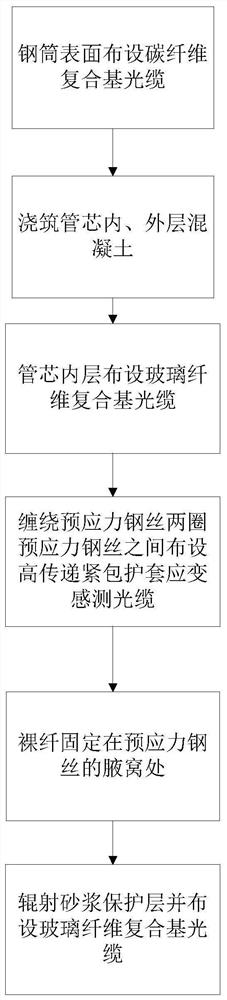

[0067] A method for manufacturing a prestressed steel cylinder concrete pipe that can monitor strain in real time, the steps are as follows

[0068] Execute steps 1 to 6, among which:

[0069] In step 1, the present embodiment selects the PCCP with 5m length and 3.4m inner diameter as an example;

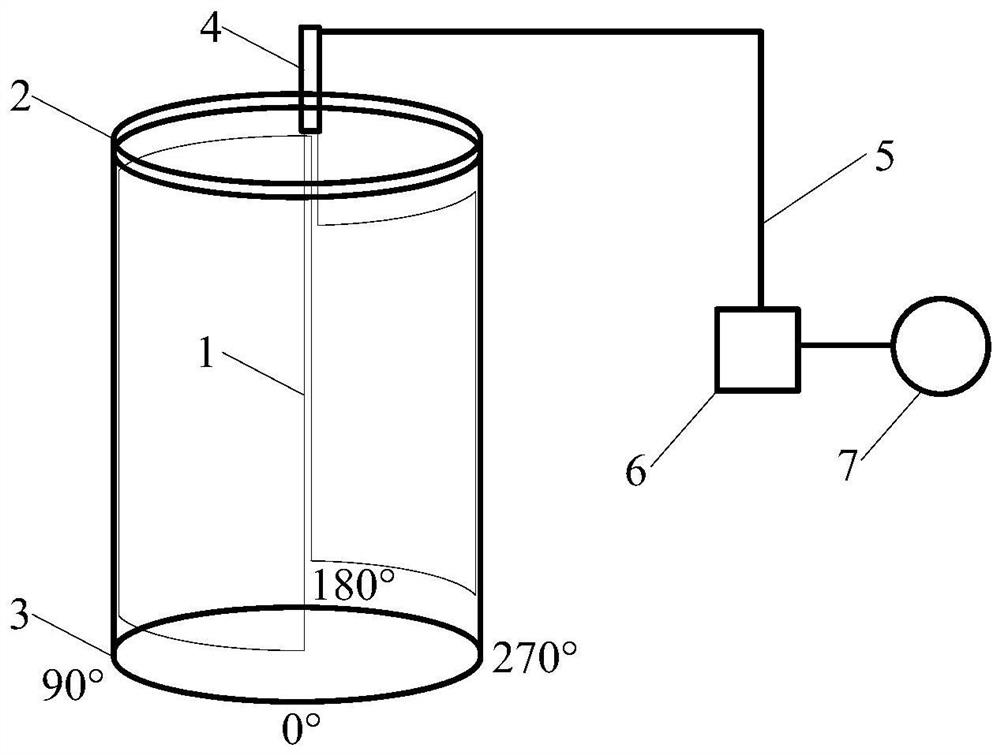

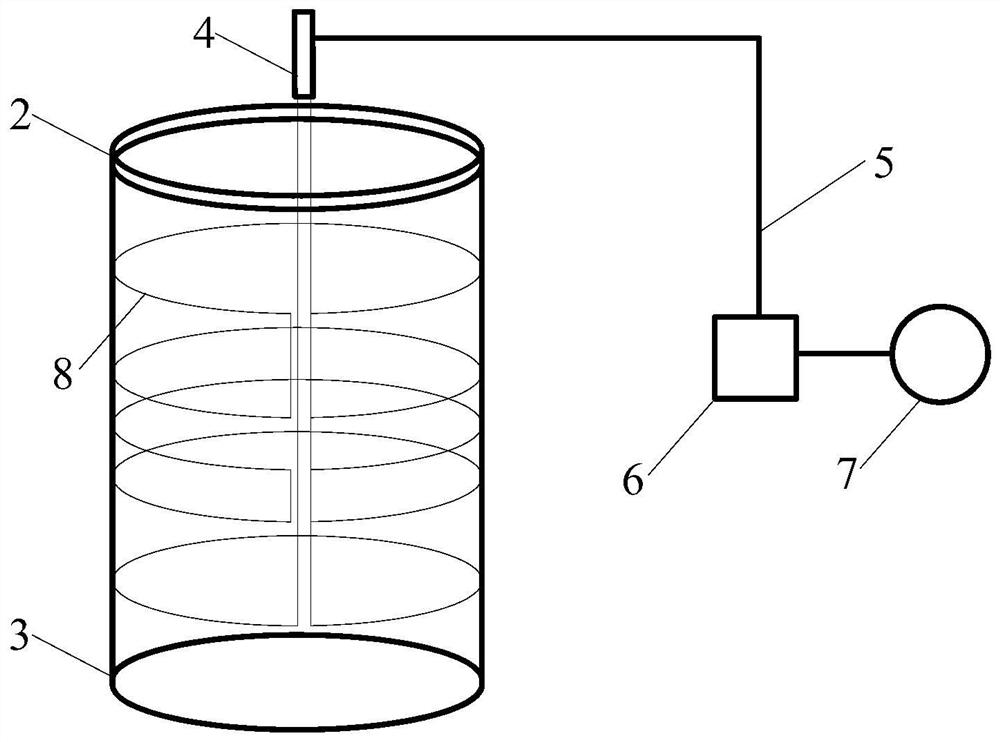

[0070] The glass fiber composite base optical cable and carbon fiber composite base optical cable in steps 1, 3, and 6 are as follows: Figure 2a , longitudinally distributed fiber 1 is fixed in four directions of 0°, 90°, 180° and 270°, such as Figure 2b The circular distributed optical fiber 2 is fixed at positions 1m, 2m, 2.5m, 3m, 4m away from the PCCP socket 3.

[0071] The protective air tubes of the lead wires are all fixed near the PCCP socket 2;

[0072] Among them, the lead-out length of the tail fiber of the glass fiber composite-based optical cable, carbon fiber composite-based optical cable, high-transmission tight-sheathed strain sensing optical cable 12, and bare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com