A method for online capacity recovery of all-vanadium redox flow battery

An all-vanadium redox flow battery and capacity recovery technology, which is applied in fuel cells, regenerative fuel cells, circuits, etc., can solve problems such as the valence imbalance of positive and negative electrolytes, achieve long-term operation, and realize online recovery and recovery good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

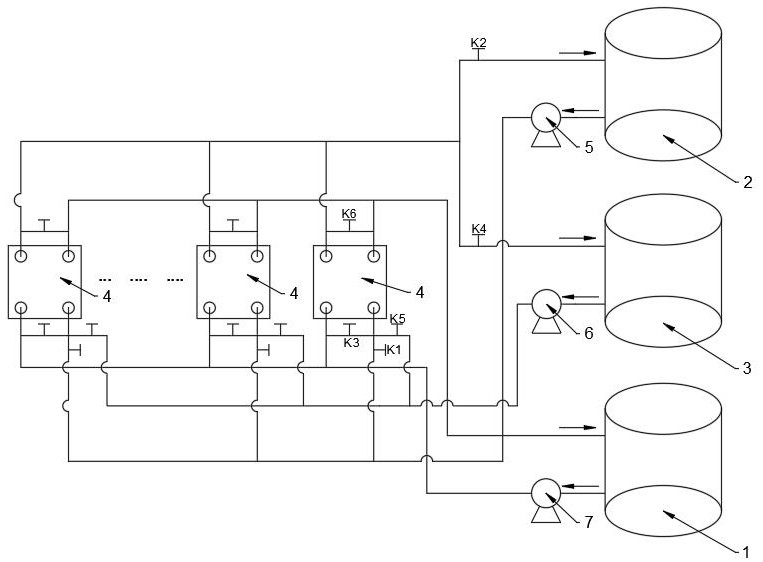

Method used

Image

Examples

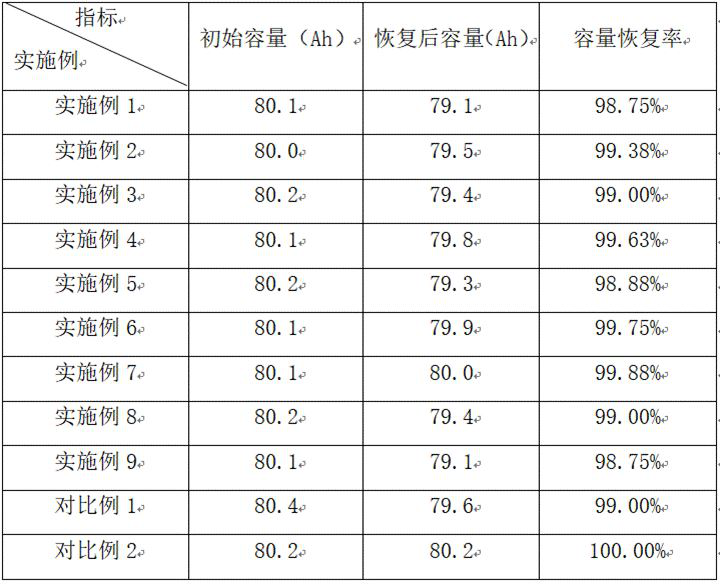

Embodiment 1

[0029]S1: When the capacity of the all-vanadium redox flow battery decays and there is a demand for capacity recovery, measure the total volume of the positive electrolyte in the positive storage tank as V + =2.0L and the total volume of the negative electrode electrolyte in the negative electrode storage tank is V - =2.0L, when the SOC of the vanadium redox flow battery is 100%, that is, the battery is fully charged, use the spectrophotometric method to detect the valence state of vanadium ions in the negative electrode electrolyte in the negative electrode storage tank online x=2.1, and the positive electrode storage tank The total concentration of vanadium ions in the positive electrolyte in the liquid tank M + =1.5mol / L and the total concentration M of vanadium ions in the negative electrode electrolyte in the negative electrode liquid storage tank - =1.5mol / L;

[0030] S2: the positive electrode electrolyte in the positive electrode liquid storage tank is divided into t...

Embodiment 2

[0035] S1: When the capacity of the all-vanadium redox flow battery decays and there is a demand for capacity recovery, measure the total volume of the positive electrolyte in the positive storage tank as V + =2.0L and the total volume of the negative electrode electrolyte in the negative electrode storage tank is V - =2.0L, when the SOC of the vanadium redox flow battery is 100%, that is, when the battery is fully charged, the valence state of vanadium ions in the negative electrode electrolyte in the negative electrode liquid storage tank is detected online by spectrophotometry x=2.2, and the positive electrode storage tank The total concentration of vanadium ions in the positive electrolyte in the liquid tank M + =1.52mol / L and the total concentration M of vanadium ions in the negative electrode electrolyte in the negative electrode liquid storage tank - =1.48mol / L;

[0036] S2: the positive electrode electrolyte in the positive electrode liquid storage tank is divided in...

Embodiment 3

[0041] S1: When the capacity of the all-vanadium redox flow battery decays and there is a demand for capacity recovery, measure the total volume of the positive electrolyte in the positive storage tank as V + =2.0L and the total volume of the negative electrode electrolyte in the negative electrode storage tank is V - =2.0L, when the SOC of the vanadium redox flow battery is 100%, that is, the battery is fully charged, use the spectrophotometric method to detect the valence state of vanadium ions in the negative electrolyte in the negative liquid storage tank online x=2.3, and the positive storage tank The total concentration of vanadium ions in the positive electrolyte in the liquid tank M + =1.55mol / L and the total concentration M of vanadium ions in the negative electrode electrolyte in the negative electrode liquid storage tank - =1.45mol / L;

[0042] S2: the positive electrode electrolyte in the positive electrode liquid storage tank is divided into two parts, and the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com