PCB manufacturing process for 5G base station communication

A technology for PCB board and base station communication, applied in the directions of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problem of reducing the communication quality and fault tolerance rate of the PCB board, increasing the weight and volume of the PCB board, and reducing the stability of the protective communication work of the PCB board. It can avoid the loosening and dislocation of components, improve convenience and work efficiency, and increase the protection and heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

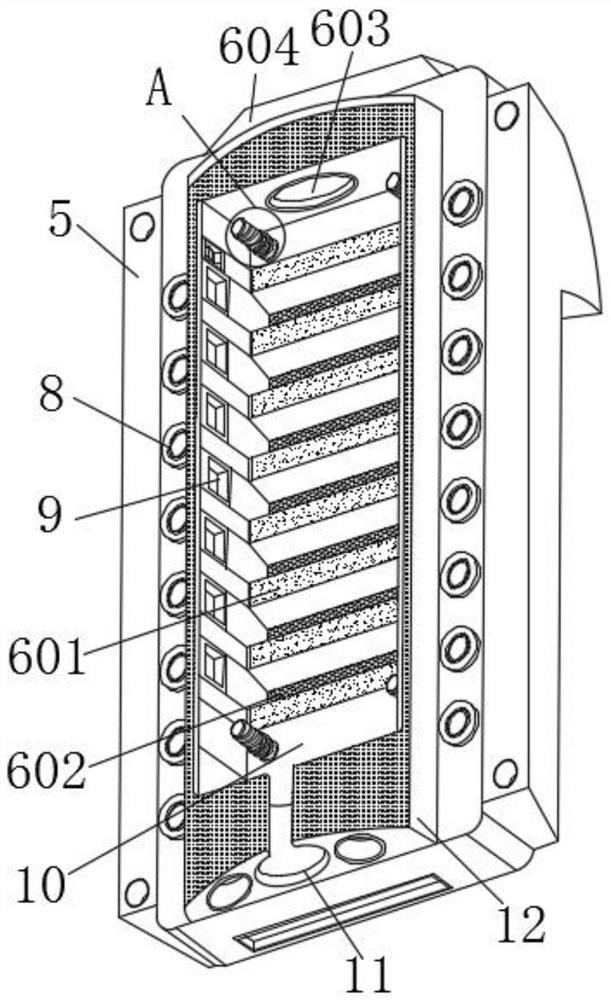

[0044] Example 1, such as Figure 3-4 As shown, when the PCB body 4 is assembled inside the groove 10, the PCB body 4 can be used to snap into the positioning bolt 703 through the positioning hole 702 provided, and the PCB body 4 is urged to stick to the spring 704, and then the PCB body 4 can be passed through The nut 701 fixes the positioning bolt 703 with threads, but does not lock the PCB body 4 to the maximum, so that the PCB body 4 can expand and contract under the elastic contact of the spring 704, avoiding the impact and vibration on the device directly acting on the PCB body 4 surfaces, providing the protection of the PCB body 4 and the stability of communication operations.

Embodiment 2

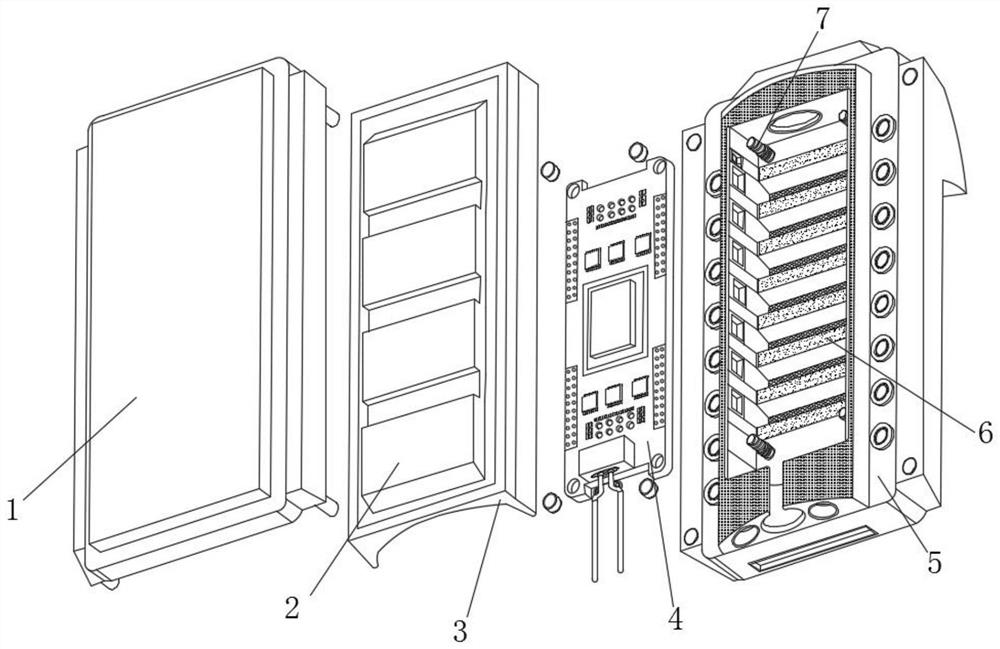

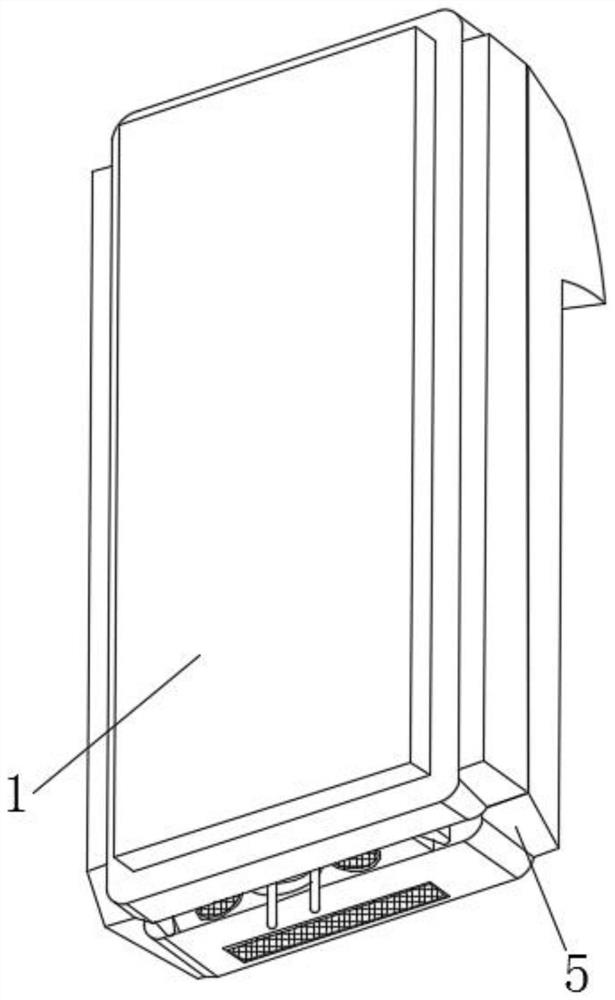

[0045] Example 2, such as Figure 1-5 As shown, when the PCB board is combined and assembled, the antenna board 2 and the curved filter board 3 can be snapped into the inner side of the fixed protective cover 1 to form an integration, and the protective cover 1 and the base 5 can be spliced together. At this time, the four sets of positioning sleeves at the four corners of the protective cover 1 are inserted into the fixing holes provided at the four corners of the base 5 for combination, and four sets of fixing bolts are used to screw the inserted positioning sleeves, so that the antenna board 2 and the arc filter The board 3 and the PCB body 4 are respectively assembled between the protective cover 1 and the base 5, which reduces the integration of the device assembly structure, promotes the overall lightweight of the PCB board, and provides convenience for subsequent base station assembly operations.

[0046] Working principle: When the device is in use, the protective co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com