Split type convenient industrial hemp cultivation system

A split technology of industrial hemp, applied in the direct liquid fertilizer delivery system, agriculture, cultivation, etc., can solve problems such as uneven distribution of spacing, insufficient light and nutrition, and inconvenient operation, so as to prevent plants from dumping, facilitate movement and Stable placement and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

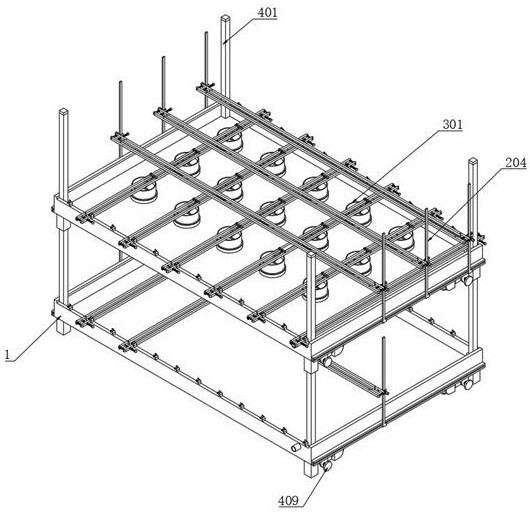

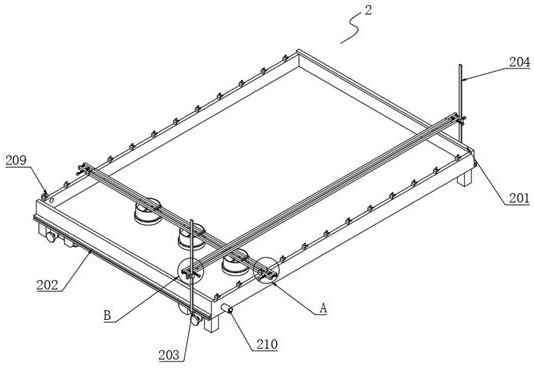

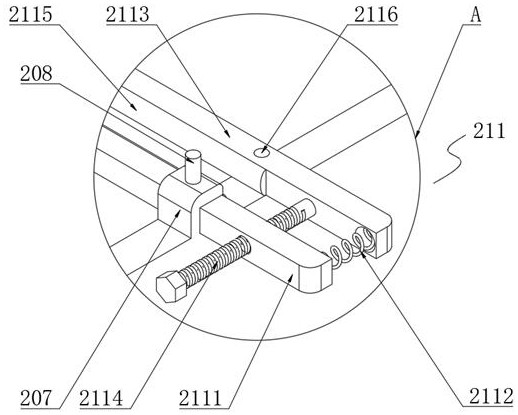

[0039] Example: such as Figure 1-4 As shown, the present invention provides a split-type convenient industrial hemp cultivation system technical solution, which includes an incubator 1, and a partition support assembly 2 is arranged inside the incubator 1. The partition support assembly 2 includes a raised side 201, a guide rail 202, a slide Block 203, guide rod 204, guide pipe 205, set screw 206, clip 207, pin 208, water inlet pipe 209, drain pipe 210 and clamping assembly 211;

[0040] The raised side 201 is symmetrically bonded to both ends of the top surface of the incubator 1, the bottom of the incubator 1 is installed with guide rails 202 through screws, the inside of the guide rail 202 is evenly slid and installed with a slider 203, and the top of the slider 203 is welded with a guide rod 204 , the middle part of the guide rod 204 is slidingly sleeved with a guide tube 205, the middle part of the guide tube 205 is threaded through and installed with a set screw 206, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com