Waste treatment system for chemical processing and working method

A technology of waste treatment and chemical industry, which is applied in the field of waste treatment system for chemical processing, can solve the problems of pollution, large space, occupancy, etc., and achieve the effects of avoiding interference, reducing floor space and reasonable structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

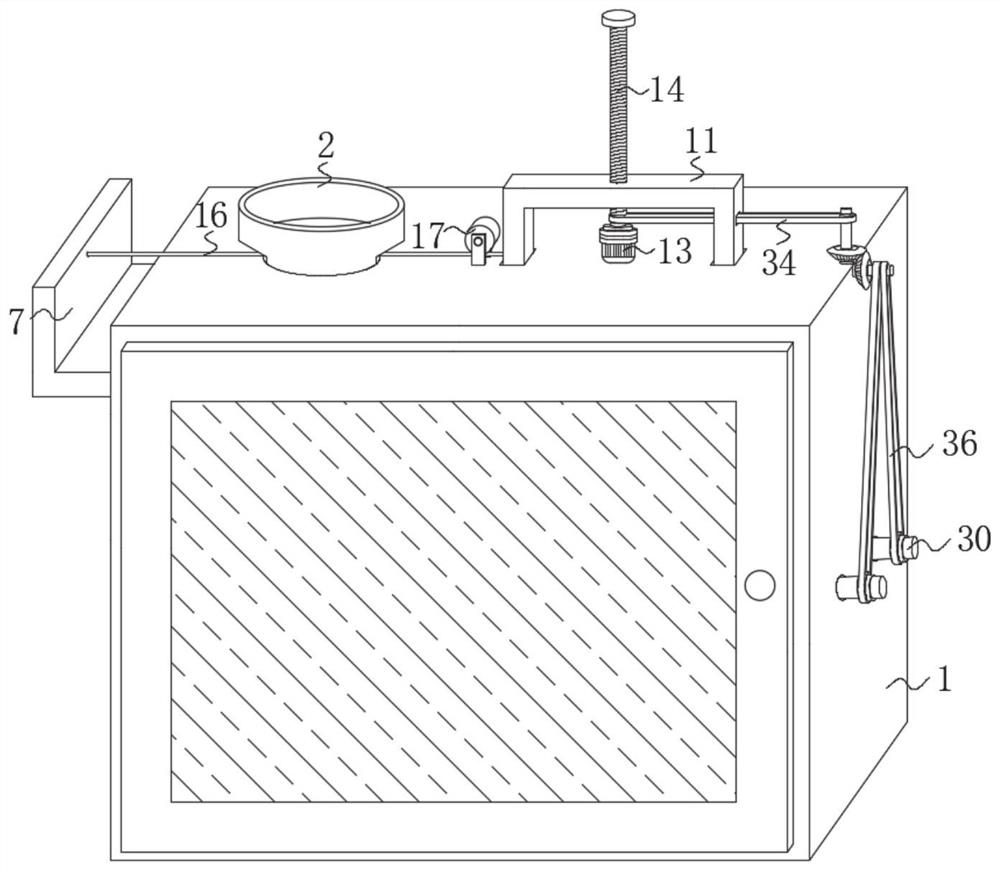

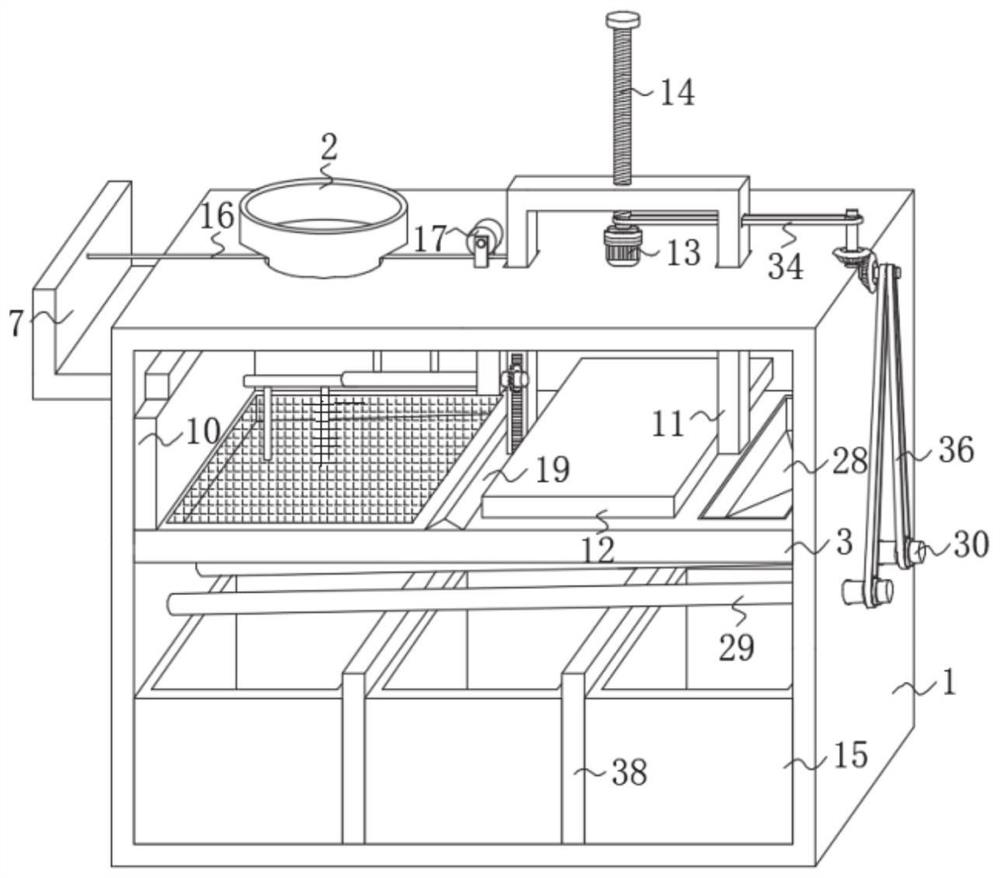

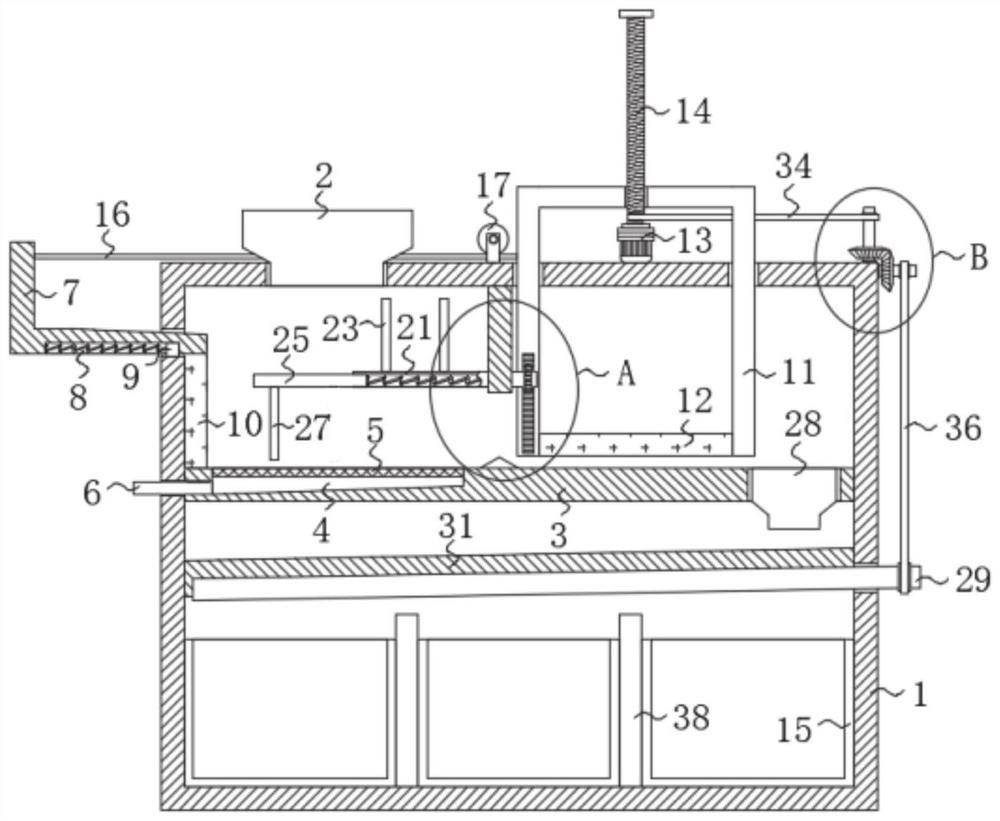

[0046] In a typical embodiment of the present invention, refer to Figure 1-Figure 3As shown, a waste treatment system for chemical processing includes a casing 1, and a feed inlet 2 is provided through the upper end of the casing. The feed inlet can be set to add chemical waste into the casing, and a support plate 3, the two ends of the support plate 3 are fixedly connected with the inner side walls of the two ends of the housing 1, the support plate is provided with a filter screen 5 below the feed port 2 to separate solid waste and liquid waste in the waste, and the support plate is below the filter screen A groove 4 is partly opened, and the groove 4 is arranged obliquely downward. The liquid separated by the filter can flow downward through the groove on the support plate with an inclined surface. The support plate supports one end of the drain pipe 6, and the drain pipe 6 is located on the filter screen. The bottom of the bottom is connected to the groove 4, and the drai...

Embodiment 2

[0058] The present invention also provides a working method of a chemical processing waste treatment system, which includes the following contents:

[0059] Pour chemical processing waste into the material inlet;

[0060] The material inlet falls into the filter screen, and the solid waste and liquid waste are separated through the filter screen. The liquid flows down, passes through the groove on the support plate, and is discharged from the drain pipe to the outside of the shell for easy collection. Support the solid waste in the waste. When the servo motor drives the threaded rod to rotate, the U-shaped plate can reciprocate up and down under the action of meshing, driving the pull rope to pull, so that the pusher plate moves towards the extrusion mechanism to push the solid to the extrusion. At the same time, the pressing mechanism moves toward the direction of the support plate to squeeze the solid. During the process of reciprocating sliding of the U-shaped plate 11 up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com