High-speed heavy-load chain scraper conveyor

A chain conveyor, high-speed technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of heavy cutting and welding processing workload, inability to meet cost-effective chain conveyors, high equipment manufacturing costs, etc. , to achieve the effect of stable equipment operation, improved conveying capacity, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

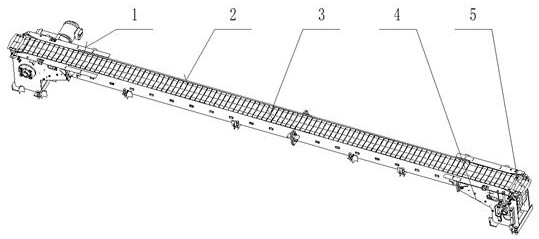

[0038] Such as figure 1 As shown, a high-speed heavy-duty chain conveyor is composed of 1-head frame part, 2-middle frame part, 3-V-shaped conveyor chain, 4-tail frame part and 5-transition device.

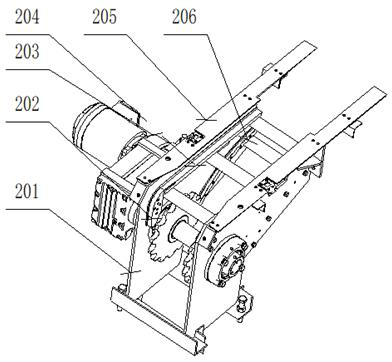

[0039] Such as figure 2 As shown, 1-head frame part includes 201-head frame, 202-arc guide rail block, 203-head upper guide rail, 204-drive component, 205-head cover plate and 206-head arc guide rail and so on. Among them, the 202-arc guide rail block is installed on the upper left part of the inner side of the 201-head frame, and its end is attached to the 203-head upper guide rail, and its upper surface is flush with the upper surface of the 203-head upper guide rail. 204- The two ends of the driving parts are installed in the bearing seat holes in the 201-head frame, the 205-head cover plate is arranged on the upper surface of the left and right side plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com