Phosphorus-free corrosion and scale inhibition integrated agent for treating circulating cooling water and preparation method of phosphorus-free corrosion and scale inhibition integrated agent

A phosphorus-free corrosion inhibition, treatment cycle technology, applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc. problem, to achieve the effect of less dosage, good corrosion and scale inhibition effect, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

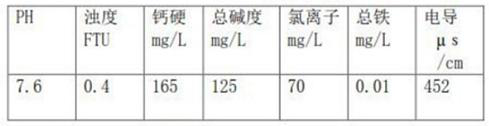

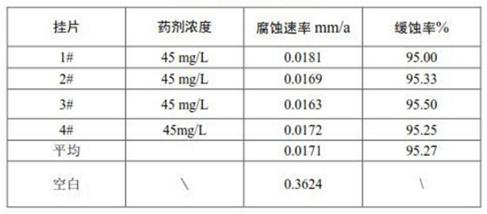

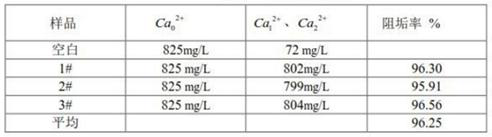

[0029] Such as Figure 1-3 As shown, the phosphorus-free corrosion and scale inhibition integrated agent for treating circulating cooling water and its preparation method include the following raw materials: sodium polyepoxysuccinate, hydrolyzed polymaleic acid, 2-acrylamido-2-methylpropane Sulfonic acid, zinc sulfate, deionized water, sodium polyepoxysuccinate 15-20%, hydrolyzed polymaleic acid 20-30%, 2-acrylamido-2-methylpropanesulfonic acid The share of zinc sulfate is 20-30%, the share of zinc sulfate is 5-10%, and the share of deionized water is 5-20%.

[0030] Further, the share of sodium polyepoxysuccinate is 18%, the share of hydrolyzed polymaleic acid is 25%, the share of 2-acrylamido-2-methylpropanesulfonic acid is 28%, and the share of zinc sulfate is 9%, and the share of deionized water is 20%.

[0031] The preparation method of the non-phosphorous corrosion and scale inhibition integrated agent for treating circulating cooling water comprises the following step...

Embodiment 2

[0042] On the basis of Example 1, as Figure 1-3 As shown, the phosphorus-free corrosion and scale inhibition integrated agent for treating circulating cooling water and its preparation method include the following raw materials: sodium polyepoxysuccinate, hydrolyzed polymaleic acid, 2-acrylamido-2-methylpropane Sulfonic acid, zinc sulfate, deionized water, sodium polyepoxysuccinate 15-20%, hydrolyzed polymaleic acid 20-30%, 2-acrylamido-2-methylpropanesulfonic acid The share of zinc sulfate is 20-30%, the share of zinc sulfate is 5-10%, and the share of deionized water is 5-20%.

[0043] Further, the share of sodium polyepoxysuccinate is 19%, the share of hydrolyzed polymaleic acid is 24%, the share of 2-acrylamido-2-methylpropanesulfonic acid is 29%, and the share of zinc sulfate is 8%, and the share of deionized water is 20%.

[0044] The preparation method of the non-phosphorous corrosion and scale inhibition integrated agent for treating circulating cooling water compri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com