Concrete mix proportion design method based on minimum slurry theory

A mix ratio design and concrete technology, which is applied in the field of concrete, can solve the problems of small concrete slump, poor work performance, and large water demand, and achieve the effects of good volume stability, balanced compressive strength, and balanced work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of concrete mix ratio design method based on the minimum slurry theory disclosed by the present invention comprises the following steps,

[0022] S1 Select slurry and aggregate, and control the difference in apparent density between the slurry and aggregate within a preset range, the slurry includes cement, admixtures and water, and the aggregate includes coarse aggregate and fine bone Fine aggregate includes machine-made sand and dredging sand accounting for 0-50.00% of the total weight of fine aggregate;

[0023] S2 According to the minimum slurry theory, determine the volume of slurry required to achieve the strength level of concrete and the volume sand ratio of fine aggregate, and then determine the amount of coarse aggregate, fine aggregate, cement, admixture and water consumption;

[0024] S3 Stir and mix the coarse aggregate, fine aggregate, cement, admixture and water according to the amount of S2 to obtain concrete.

Embodiment 2

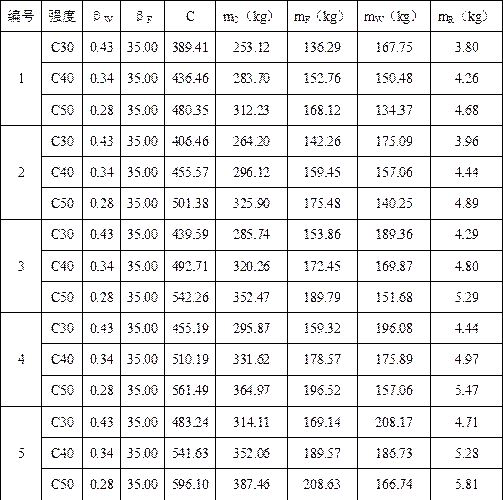

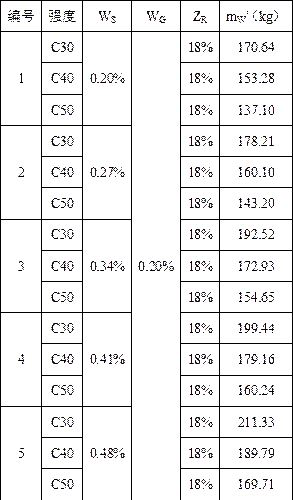

[0025] Embodiment 2: A concrete mix design method based on the minimum slurry theory disclosed in the present invention, the difference from Example 1 is that S1 selects slurry and aggregate, and controls the relationship between slurry and aggregate. The density difference is within the preset range, wherein the slurry includes cement, admixtures composed of fly ash, water, aggregates include coarse aggregates composed of crushed stones of 2.36~19.00mm, dredging sand and mechanism fine aggregate composed of sand; at the same time, set the dredging sand replacement rate (that is, the weight percentage of dredging sand in the fine aggregate) to 0~50.00%, and measure it according to the methods of GB / T208-94 and GB / T14685-2001 , to obtain the apparent density ρ of cement, admixture, water, fine aggregate and coarse aggregate C , ρ F , ρ W , ρ S , ρ G , the apparent density is shown in Table 1;

[0026] Table 1

[0027] Numbering dredged sand replacement rate ρ ...

Embodiment 3

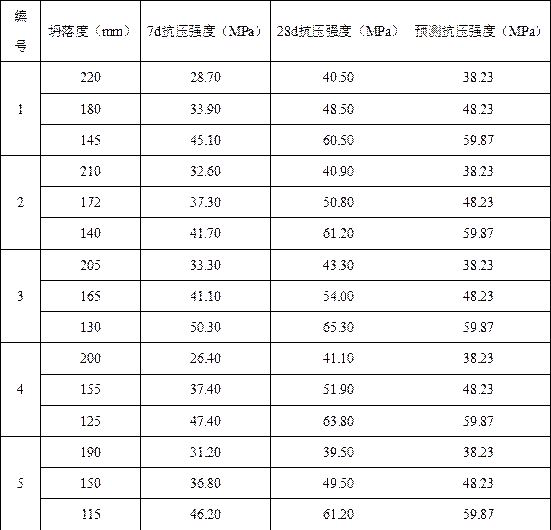

[0028]Embodiment 3: It is a concrete mix ratio design method based on the minimum slurry theory disclosed in the present invention. The difference from Example 1 is that S2 determines the concrete that can reach the strength level of C30~C50 according to the minimum slurry theory The required slurry volume and the corresponding volume sand ratio of fine aggregate, and then determine the amount of coarse aggregate, fine aggregate, cement, admixture and water consumption. The specific implementation method is as follows.

[0029] S21 Determine the formula for calculating the volume of slurry

[0030] 1) V P =m C / ρ C +m F / ρ F +m W / ρ W ;

[0031] 2) V P =APT*S+V V ;

[0032] Among them, S=m S *R S +m G *R G =y S *ρ S *R S +(1-y S )*ρ G *R G ;

[0033] V V = (1-φ A ) / φ A ;

[0034] In the formula, V P is the slurry volume; APT is the average slurry thickness of the wrapped aggregate; S is the total surface area of fine aggregate and coarse aggregate p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com