Preparation method of high-whiteness thermosensitive color developing agent containing sulfonylurea structure

A technology containing sulfonylurea and high whiteness, which is applied in the field of preparation of heat-sensitive developer, which can solve the problem that the purity of color developer and whiteness affect the quality of thermal paper, the preparation process is cumbersome and complicated, and the heat-sensitive paper is dark. problems, to achieve the effect of preventing poor color, improving the purity of filter cake, and preventing oxidation and discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

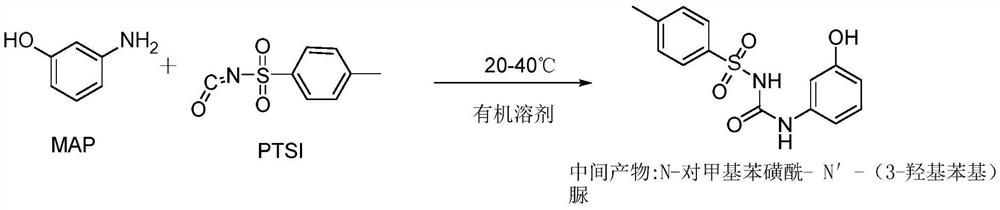

Method used

Image

Examples

Embodiment 1

[0031] One-step reaction: feed N into reactor 1 2 , add 500L DMAC after air replacement, start stirring, add 272.75kg (2.50kmol) m-aminophenol (MAP), after dissolving at 40°C, slowly add 517.65kg (2.63kmol) p-toluenesulfonyl isocyanate (PTSI), The dropping time is 2.5 hours, and the temperature is kept at 40° C., and the temperature is kept for 2 hours to reach the end point.

[0032] Two-step reaction: p-toluenesulfonyl chloride (PTSC) solution configuration: 524.42kg (2.75kmol) PTSC was dissolved in 525L DMAC.

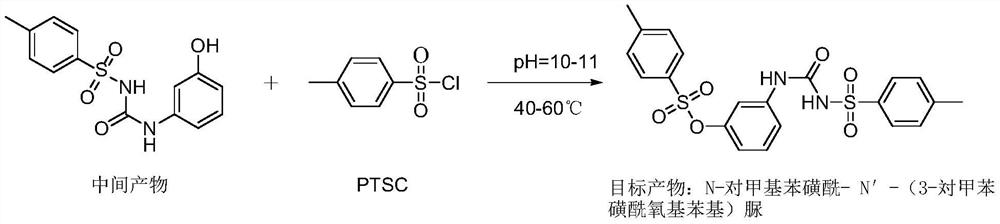

[0033] Transfer the material in the reactor 1 to N 2 In the reaction kettle 2 of the atmosphere, pump 1196kg (2.99kmol) of 10% NaOH solution in the reaction kettle 2, the system pH=10-11, slowly add the DMAC solution of p-toluenesulfonyl chloride (PTSC) dropwise, and simultaneously add 30 300kg (2.25kmol) of % NaOH was dissolved to ensure that the pH of the system was 10-11, the temperature was between 40-60°C, the dropping time was 1.0h, and the temperature was ke...

Embodiment 2

[0039] One-step reaction: feed N into reactor 1 2, add 750L DMAC after air replacement, start stirring, add 272.75kg (2.50kmol) m-aminophenol (MAP), after dissolving at 30°C, slowly add 542.3kg (2.75kmol) p-toluenesulfonyl isocyanate (PTSI), The dropping time is 3.5 hours, and the temperature is kept at 30° C., and the temperature is kept for 1.5 hours to reach the end point.

[0040] Two-step reaction: p-toluenesulfonyl chloride (PTSC) solution configuration: 572.10kg (3.00kmol) PTSC was dissolved in 720L DMAC.

[0041] Transfer the material in the reactor 1 to N 2 In the reaction kettle 2 of the atmosphere, pump 20% NaOH solution 598kg (2.99kmol) in the reaction kettle 2, the system pH=10-11, slowly add the DMAC solution of p-toluenesulfonyl chloride (PTSC) dropwise, and simultaneously add 20 Dissolve 513.31kg (2.57kmol) of % NaOH, ensure the pH of the system is 10-11, the temperature is between 40-60°C, the dropwise addition time is 1.5h, and keep warm for 1h to reach the...

Embodiment 3

[0047] One-step reaction: feed N into reactor 1 2 , add 1000L DMAC after air replacement, start stirring, add 272.75kg (2.50kmol) m-aminophenol (MAP), after dissolving at 20°C, slowly add 566.95kg (2.88kmol) p-toluenesulfonyl isocyanate (PTSI), The dropping time is 4.0h, and the temperature is kept at 30°C, and the temperature is kept for 1h to reach the end point.

[0048] Two-step reaction: p-toluenesulfonyl chloride (PTSC) solution configuration: 619.78kg (3.25kmol) PTSC was dissolved in 900L DMAC.

[0049] Transfer the material in the reactor 1 to N 2 In the reaction kettle 2 of the atmosphere, pump 15% Na in the reaction kettle 2 2 CO 3 Solution 1060kg (1.5kmol), system pH=10-11, slowly add dropwise the DMAC solution of p-toluenesulfonyl chloride (PTSC), simultaneously dropwise add 40% NaOH to dissolve 280kg (2.80kmol), guarantee system pH=10-11, temperature The temperature is between 40-60°C, the dropping time is 1.5h, and the temperature is kept for 1h to reach the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com