Corynebacterium glutamicum for high yield of L-proline and method for high yield of L-proline

A technology of Corynebacterium glutamicum and proline, applied in the fields of molecular biology and bioengineering, can solve the problems of low L-proline yield and the like, and achieve the effects of facilitating popularization and application, and improving transformation rate and production intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

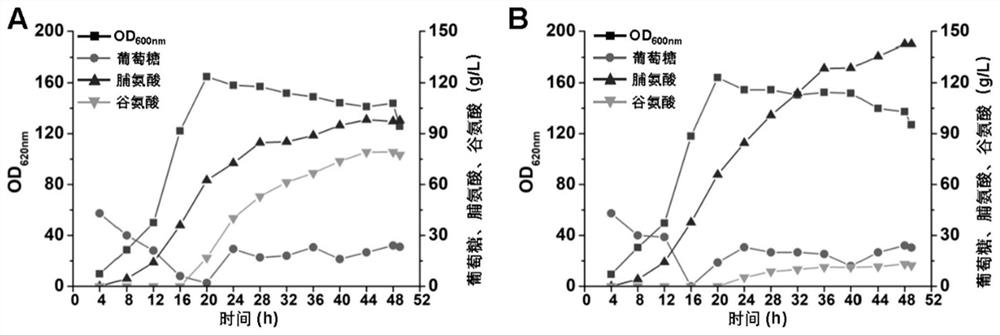

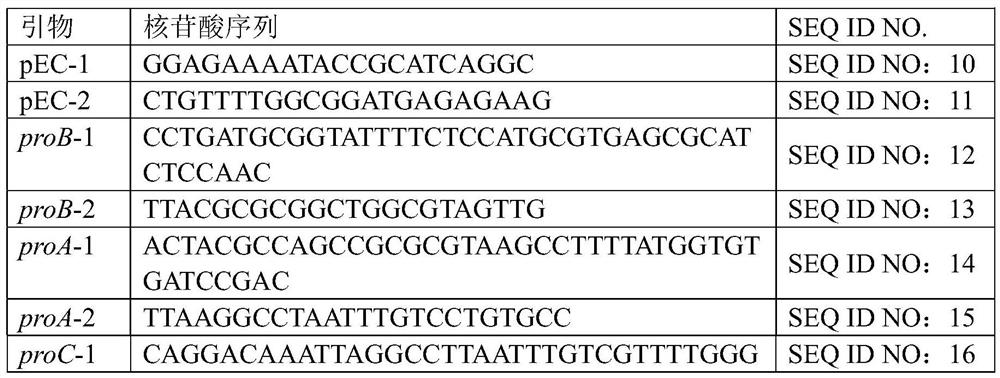

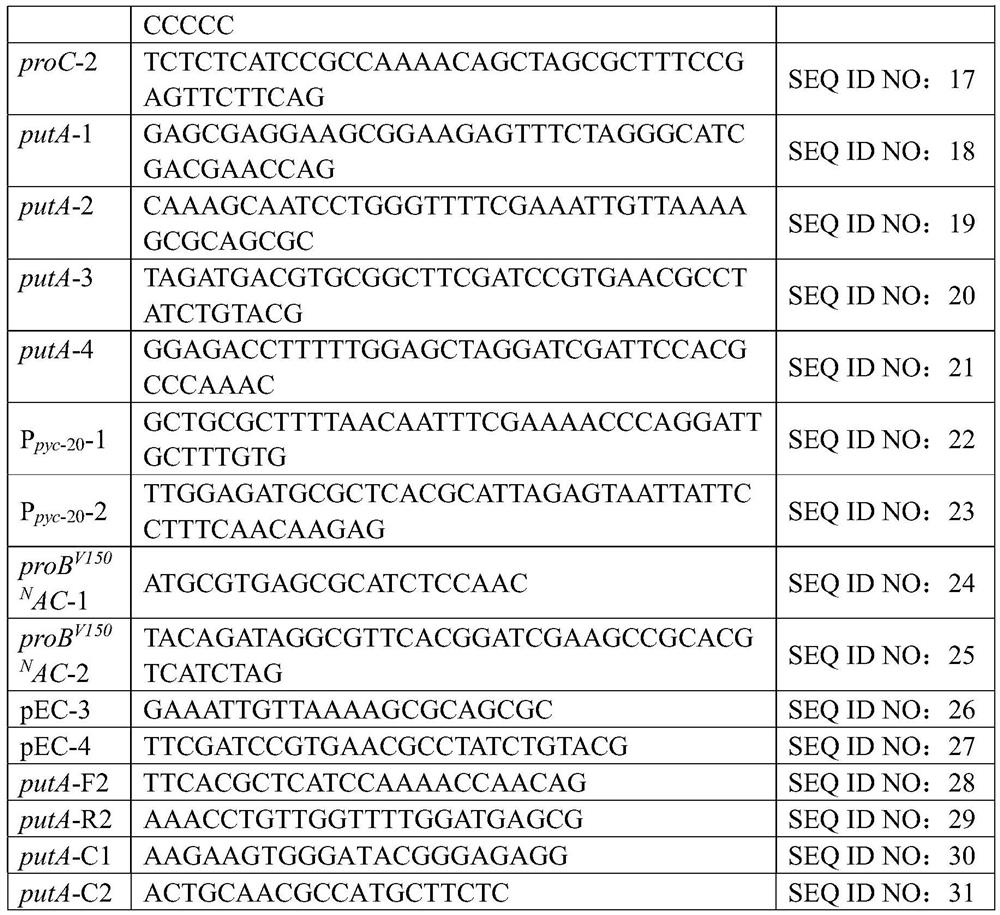

[0049] Embodiment 1, insert the proB of artificial copy V150N The AC operon and blocking L-proline degradation enhance L-proline production

[0050] Based on Corynebacterium glutamicum ATCC13032 (Gene ID: 2830649), the SLCgP54 (CN112111469B, ProB introduces the V150N mutation) bacterial strain that releases the L-proline feedback inhibition of γ-glutamyl kinase ProB is the starting strain, and the present invention is defined as PRO-1 strain. At the same time, the inventors mutated the pyc promoter of the endogenous pyruvate carboxylase gene pyc in Corynebacterium glutamicum in the early stage, and obtained a series of promoter mutants with significantly improved promoter activity, among which P pyc-20 (The sequence is shown as SEQ ID NO: 8) is the most active promoter, and the expression intensity is 16.1 times higher than that of the wild-type promoter.

[0051] The present invention further enhances L-proline synthesis by enhancing the expression of three key enzymes ProB...

Embodiment 2

[0067] Embodiment 2, enhancing the expression of glutamate dehydrogenase gdh gene improves L-proline output

[0068] L-glutamic acid is the precursor of L-proline synthesis, in order to enhance the activity of glutamate dehydrogenase and then enhance the supply of glutamic acid precursor to increase the production of L-proline, the present invention adopts the enhanced activity of the gene itself The promoter mutation is directly modified in situ on the chromosome to achieve enhanced expression of the target gene, that is, the promoter mutant with increased expression intensity enhances the expression of the glutamate dehydrogenase gdh (gene number Cgl2079) gene. The inventors mutated the endogenous glutamate dehydrogenase gdh promoter of Corynebacterium glutamicum in the early stage, and obtained a series of promoter mutants with significantly improved promoter activity, among which P gdh-16 ,P gdh-23 ,P gdh-26 ,P gdh-29 Promoter mutants (sequences as shown in SEQ ID NO: 1...

Embodiment 3

[0078] Example 3, Enhancing the expression of pyruvate carboxylase pyc gene to improve L-proline production

[0079] In order to enhance the activity of pyruvate carboxylase and then strengthen the supply of oxaloacetate to increase the production of L-proline, the present invention adopts the enhanced activity promoter mutation of the gene itself to directly modify the expression of the target gene in situ on the chromosome, that is, Promoter mutants with increased expression strength were achieved by enhancing the expression of the pyruvate carboxylase pyc (Cgl0689) gene. The inventors mutated the endogenous pyruvate carboxylase pyc promoter of Corynebacterium glutamicum in the early stage, and obtained a series of promoter mutants with significantly improved promoter activity, among which P pyc-13 ,P pyc-16 ,P pyc-20 The expression intensity of the promoter (sequence shown in SEQ ID NO: 6, SEQ ID NO: 7, and SEQ ID NO: 8) is 8.9, 12.1, and 16.1 times higher than that of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com