A kind of preparation method of copper sleeve

A copper sleeve and forming equipment technology, applied in the direction of manufacturing tools, heat treatment equipment, process efficiency improvement, etc., can solve the problems of copper sleeve strength and hardness decrease, etc., achieve strength and hardness improvement, remove residual stress, and improve driving energy. Effect

Active Publication Date: 2022-06-03

CHINA WEAPON SCI ACADEMY NINGBO BRANCH

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the strength and hardness of the copper sleeve tend to decrease after annealing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Login to View More

Abstract

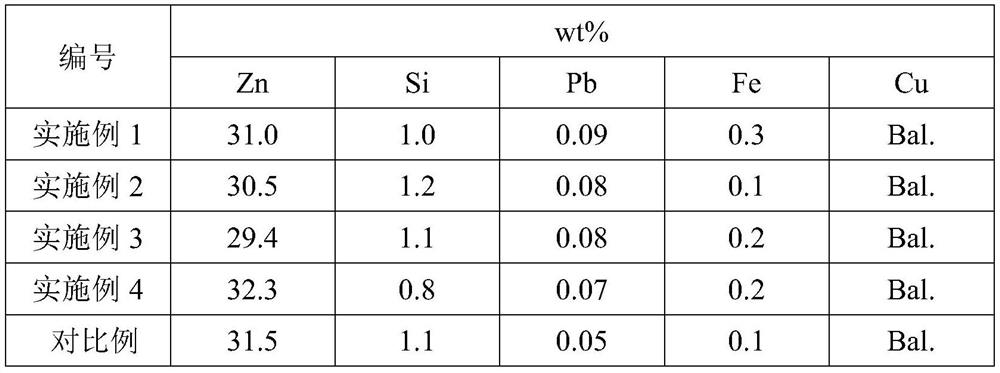

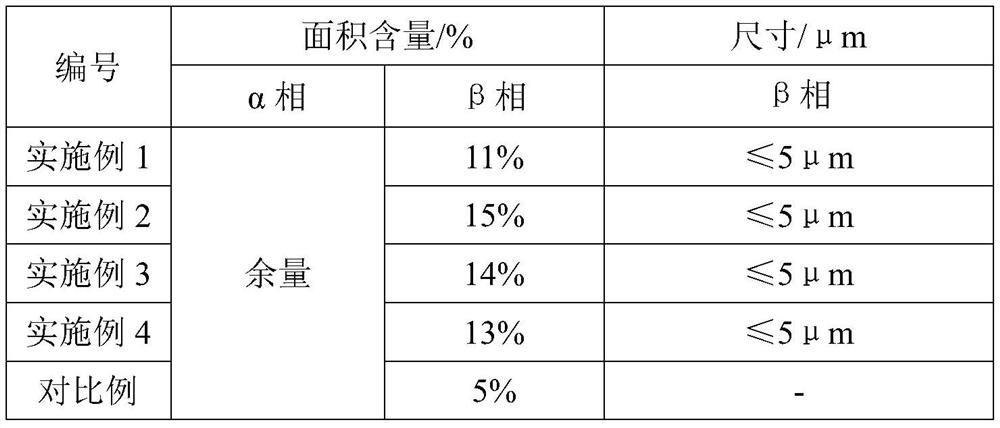

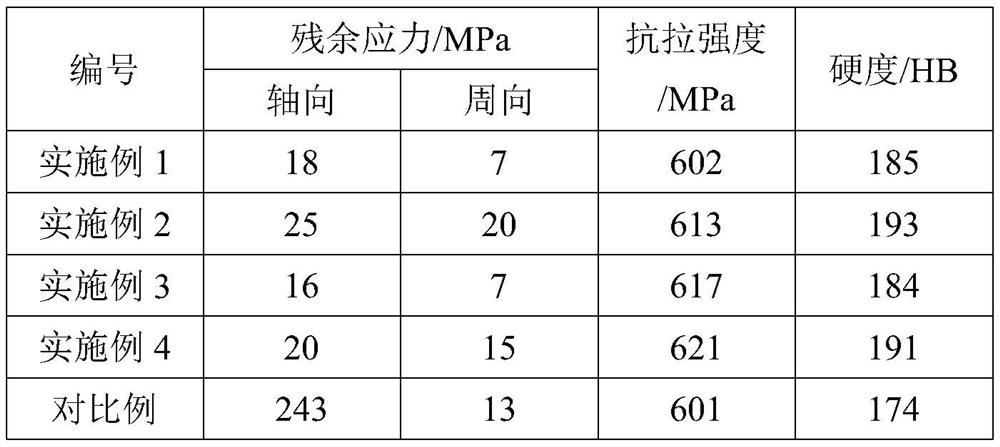

The invention discloses a preparation method of a copper sleeve, which is characterized in that: the mass percentage of the copper sleeve is composed of Zn: 28.5-33.5%, Si: 0.7-1.3%, Pb≤0.1%, Fe≤0.5%, and the balance It is Cu and unavoidable impurities; the preparation process of the copper sleeve includes: casting → forming → quenching → annealing; when quenching, the transfer time from removing the copper sleeve from the forming equipment to quenching into the water tank is not more than 15s; the annealing The temperature is 250 ℃ ~ 300 ℃, the holding time is 2h ~ 3h, and air cooling after taking out the copper sleeve. In the invention, quenching is carried out after forming, which not only ensures the strength and hardness of the copper sleeve, but also largely removes the residual stress produced by plastic deformation. Annealing after quenching, the annealing temperature is controlled below the recrystallization temperature of the copper sleeve, which avoids the performance degradation of the material due to recrystallization, and further removes the residual stress inside the material.

Description

A kind of preparation method of copper sleeve technical field The present invention relates to a kind of preparation method of copper sleeve. Background technique The copper sleeve is one of the main parts of the engine. The plug pin is a clearance fit, which is used to reduce the surface contact stress of the piston pin hole and the connecting rod, and improve the reliability of the work. Traditional copper sleeve preparation adopts the mode of cold drawing after extrusion to obtain finished product, but in the forming process, the plastic The inhomogeneous deformation and material flow deformation lead to the generation of residual stress. Residual stress will change the performance of copper sleeve , resulting in problems such as deformation and dimensional accuracy changes during processing, and even cracking during use, resulting in As a result, the entire piston-rod mechanism fails. The method for removing residual stress at present mainly contains natural...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22F1/08C21D9/00C22C9/04

CPCC22F1/08C22F1/002C21D9/0068C22C9/04Y02P10/20

Inventor 洪晓露徐恒秋黄涛郭亚明彭银江徐英陈大辉朱鸿磊张将刘永强侯林冲

Owner CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com