Refrigerating system, control method and air conditioner

A refrigeration system and control method technology, applied in refrigerators, refrigeration components, air conditioning systems, etc., can solve problems such as affecting compressor life, compressor discharge temperature and discharge pressure exceeding specified values, compressor liquid hammer, etc. achieve the effect of avoiding the greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

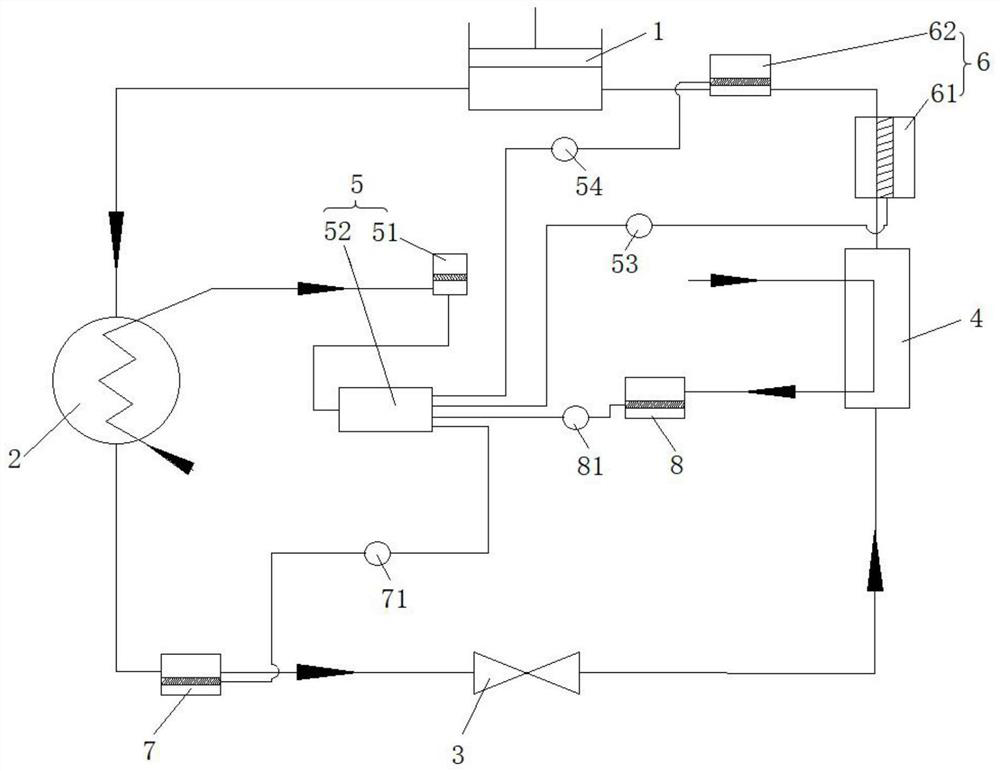

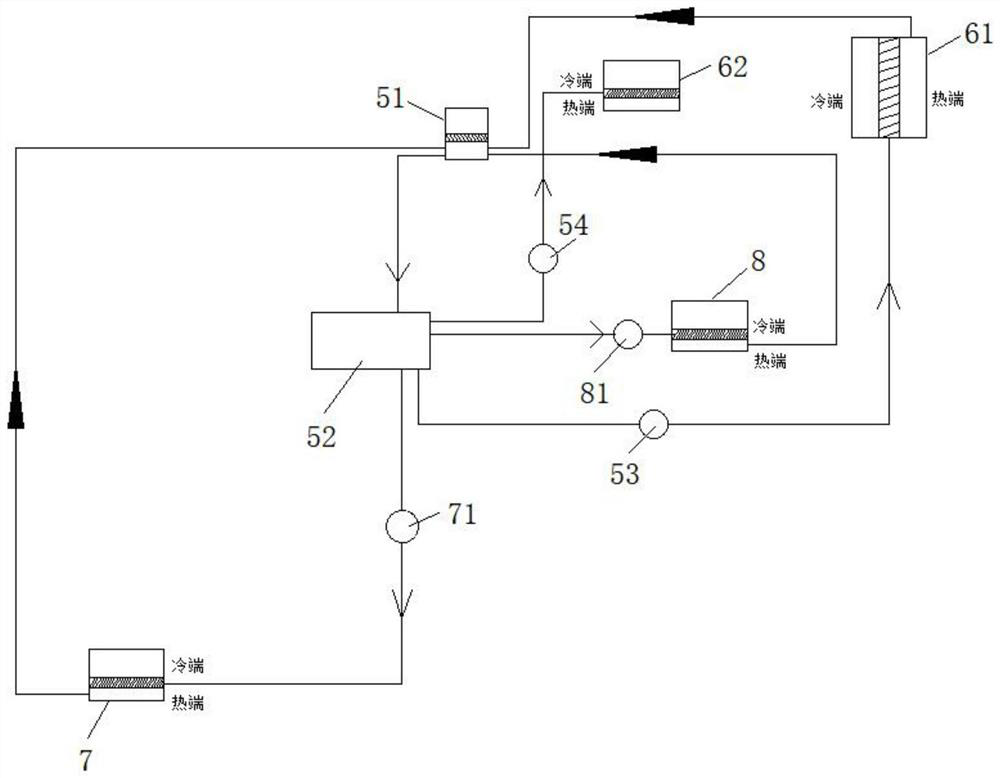

[0042] This embodiment provides a refrigeration system, such as figure 1 and figure 2 As shown, the refrigeration system includes a compressor 1, a condenser 2, a throttle valve 3, and an evaporator 4, an inlet connection of the compressor 1 and the inlet of the condenser 2 and the inlet of the throttle valve 3. Connect, the outlet of the throttle valve 3 is connected to the inlet of the evaporator 4, and the outlet of the evaporator 4 is connected to the suction port of the compressor 1;

[0043] The refrigeration system also includes an electric storage assembly 5 disposed on the wind side of the condenser 2 and a semiconductor refrigeration assembly 6 disposed between the compressor 1 and the evaporator 4, and the power storage component 5 recovers the heat release of the condenser 2 for use in The semiconductor refrigeration assembly 6 provides electrical energy, and the semiconductor refrigeration assembly 6 is used to adjust the suction overheating value of the compressor 1....

Embodiment 2

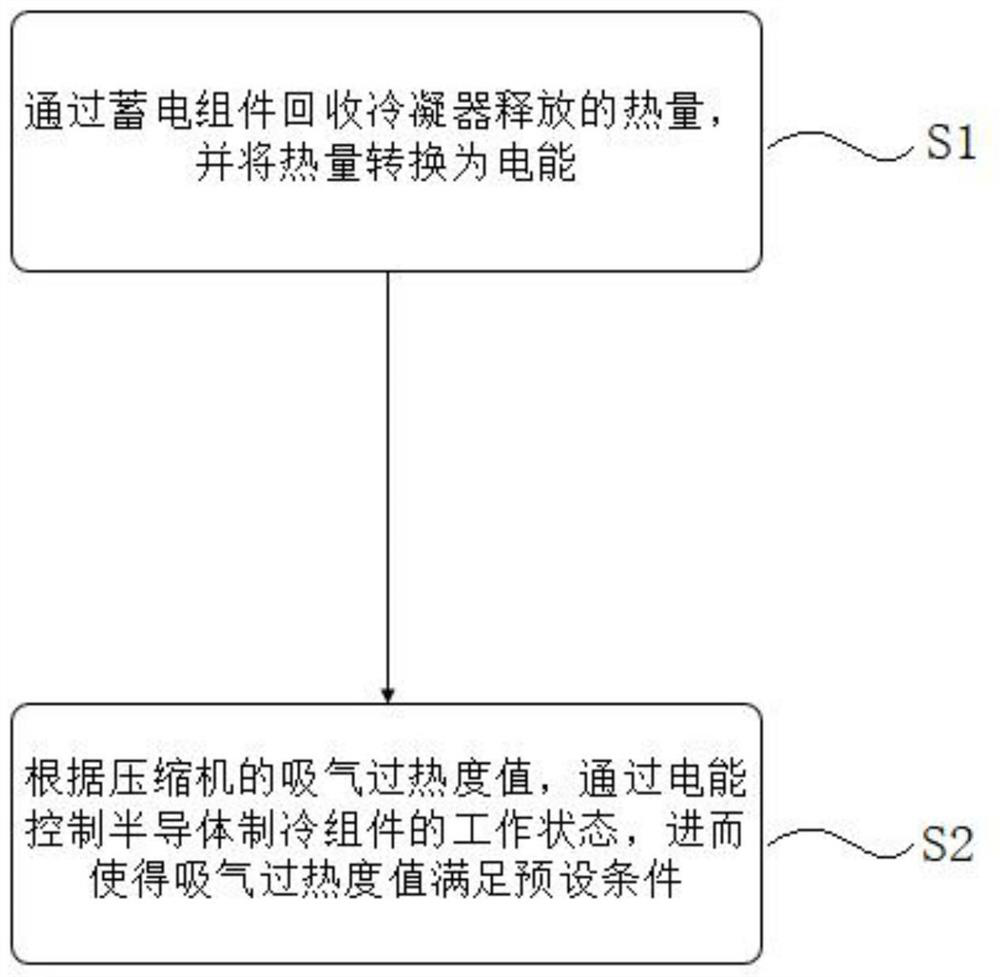

[0084] This embodiment provides a method of controlling a refrigeration system, such as image 3 As shown, the control method includes the steps of:

[0085] S1, the calorifier 2 released by the power storage component 5 and converts heat into electrical energy;

[0086] S2, according to the suction overheating value of the compressor 1, by the electrical energy controls the working state of the semiconductor refrigeration assembly 6, thereby causing the suction overheating value to satisfy the preset conditions.

[0087] In the specific embodiment:

[0088] The calorifier 2 released by the power storage component 5, and the heat is converted into electrical energy, specifically:

[0089] The heat released by the condenser 2 increases the temperature of the hot end of the semiconductor temperature difference generator 51 to generate electrical energy through the temperature difference of the cold end through the hot end of the semiconductor temperature difference generator 51 and t...

Embodiment 3

[0100] This embodiment provides an air conditioner that includes a refrigeration system in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com