Material sample shearing and fixing device and metal gas content analysis sample preparation method

A technology of fixing devices and metal materials, which is applied in the field of material processing, can solve the problems of potential safety hazards and poor uniformity, and achieve the effects of low cost, good uniformity, and simple and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

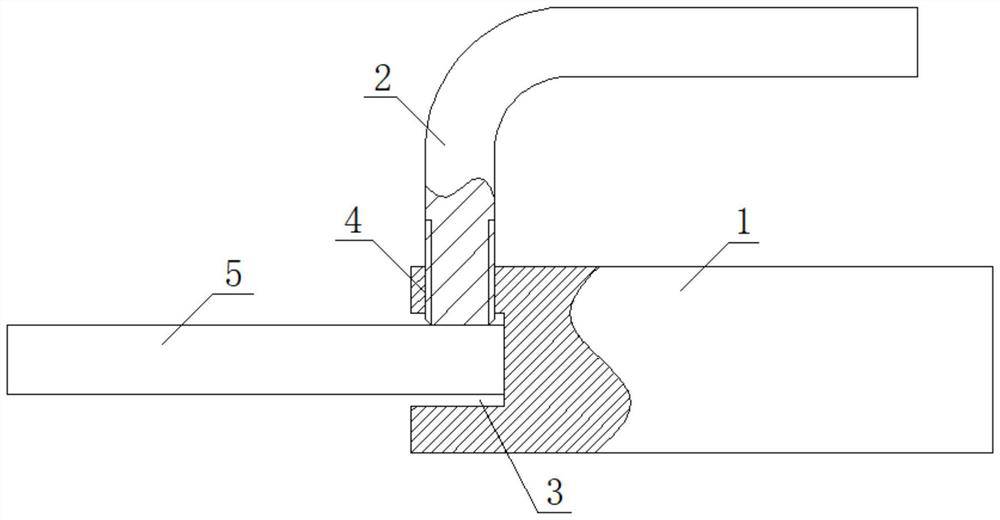

[0020] see figure 1 , The material sample shearing and fixing device of the present invention includes a base body 1 and a fastener 2, a reference plane is set on the base body 1, the reference plane is a plane, and a positioning hole 3 is set on the reference plane. The positioning hole 3 is used to accommodate the material sample that needs to be sheared, and the positioning hole 3 can be a blind hole or a through hole. The positioning hole 3 is preferably a blind hole, and the material sample to be cut can be inserted into the bottom of the positioning hole 3, so as to control the length of the cut material. The material sample that needs to be cut can be inserted into the bottom of the positioning hole 3, and then sheared after being fixed; or not inserted into the bottom of the positioning hole 3, and then sheared after being fixed. One side of the positioning hole 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com