Method for rapidly testing moisture content of sized and dried carbon fibers

A technology of moisture content after drying, which is applied in the field of detection to achieve the effect of avoiding quality errors and fast testing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

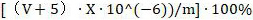

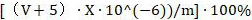

Embodiment 1

[0055] Take about 5g of fiber sample A after sizing and drying and weigh it with a balance with a precision of 0.01mg. The accurate mass is 5.03281g. After 7 minutes, take out the fiber from the acetone solvent. During the process of taking out the fiber, squeeze the acetone solvent attached to the fiber back into the glass container so that the solvent attached to the fiber does not appear in the form of droplets. Then use the precision scale that comes with the airtight container to quickly read the remaining solvent volume as 141.2ml, accurately sample 1ml from the remaining acetone solvent, and quickly test the water content in this 1ml acetone solvent with a Karl Fischer trace moisture analyzer. 10.2μg / ml . At the same time, TGA is used to determine whether there is sizing agent residue on the above-mentioned fibers after soaking and desizing. The TGA test condition is: nitrogen atmosphere, and the temperature is raised from 50°C to 500°C at a heating rate of 30°C / min. T...

Embodiment 2

[0057] Take about 5g of fiber sample B after sizing and drying and weigh it with a balance with a precision of 0.01mg. The accurate mass is 5.12831g. After 5 minutes, take out the fiber from the acetone solvent. During the process of taking out the fiber, squeeze the acetone solvent attached to the fiber back into the glass container so that the solvent attached to the fiber does not appear in the form of droplets. Then use the precision scale that comes with the airtight container to quickly read the remaining solvent volume as 170.8ml, accurately sample 1ml from the remaining acetone solvent, and quickly test the water content in this 1ml acetone solvent with a Karl Fischer trace moisture analyzer to be 10.8μg / ml . At the same time, TGA is used to determine whether there is sizing agent residue on the above-mentioned fibers after soaking and desizing. The TGA test condition is: nitrogen atmosphere, and the temperature is raised from 50°C to 500°C at a heating rate of 50°C / min ...

Embodiment 3

[0059] Take about 5g of fiber sample C after sizing and drying and weigh it with a balance with a precision of 0.01mg. The accurate mass is 5.19228g. After 5 minutes, take out the fiber from the acetone solvent. During the process of taking out the fiber, squeeze the acetone solvent attached to the fiber back into the glass container so that the solvent attached to the fiber does not appear in the form of droplets. Then use the precision scale that comes with the airtight container to quickly read the remaining solvent volume as 191.3ml, accurately sample 1ml from the remaining acetone solvent, and quickly test the water content in this 1ml acetone solvent with a Karl Fischer trace moisture analyzer to be 11.5μg / ml . At the same time, TGA is used to determine whether there is sizing agent residue on the above-mentioned fibers after soaking and desizing. The TGA test condition is: nitrogen atmosphere, and the temperature is raised from 50°C to 500°C at a heating rate of 50°C / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com