High-speed silicon light modulator phase shift arm and preparation method thereof

A modulator and silicon photonics technology, applied in the field of optical communication, to achieve the effect of increasing bandwidth and increasing optical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

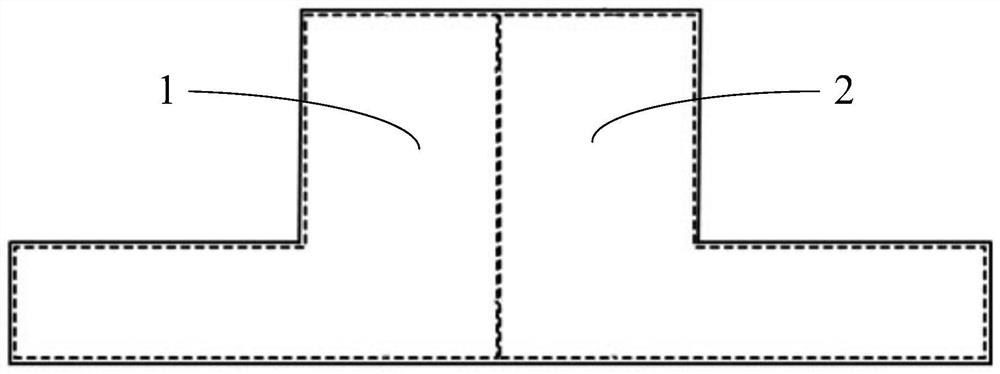

[0049] An embodiment of the present invention provides a high-speed silicon optical modulator phase shift arm, such as figure 1 As shown, it includes: a ridge waveguide; the P-type doped region and the N-type doped region are respectively located on both sides of the ridge-shaped waveguide.

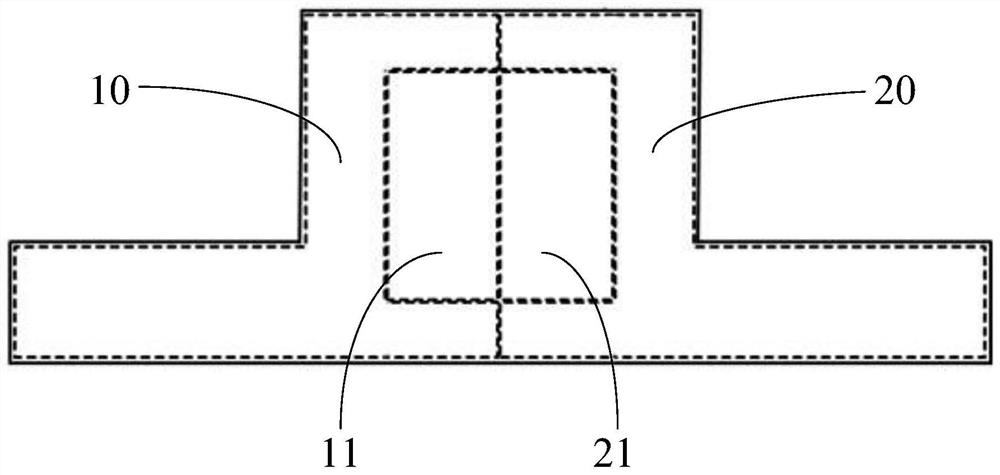

[0050] Such as figure 2 As shown, the P-type doped region includes a P-type heavily doped region and a P-type lightly doped region; the P-type heavily doped region is located at the boundary region of the ridge waveguide, and the P-type lightly doped region is located at the ridge waveguide core region of the waveguide.

[0051] The N-type doped region includes an N-type heavily doped region and an N-type lightly doped region; the N-type heavily doped region is located at the boundary region of the ridge waveguide, and the N-type lightly doped region is located at the core of the ridge waveguide area.

[0052] Wherein, the average doping concentration of the P-type heavily doped regio...

Embodiment 2

[0068] An embodiment of the present invention provides a method for preparing a phase shift arm of a high-speed silicon optical modulator. By ion implantation doping, a P-type heavily doped region and an N-type heavily doped region are arranged in the boundary region of a ridge waveguide, and a P-type The lightly doped region and the N-type lightly doped region are arranged in the core region of the ridge waveguide.

[0069] Wherein, the average doping concentration of the P-type heavily doped region is higher than the average doping concentration of the P-type lightly doped region; the average doping concentration of the N-type heavily doped region is higher than that of the N-type lightly doped region The average doping concentration of the ridge waveguide; the optical field intensity in the boundary region of the ridge waveguide is smaller than that in the core region of the ridge waveguide.

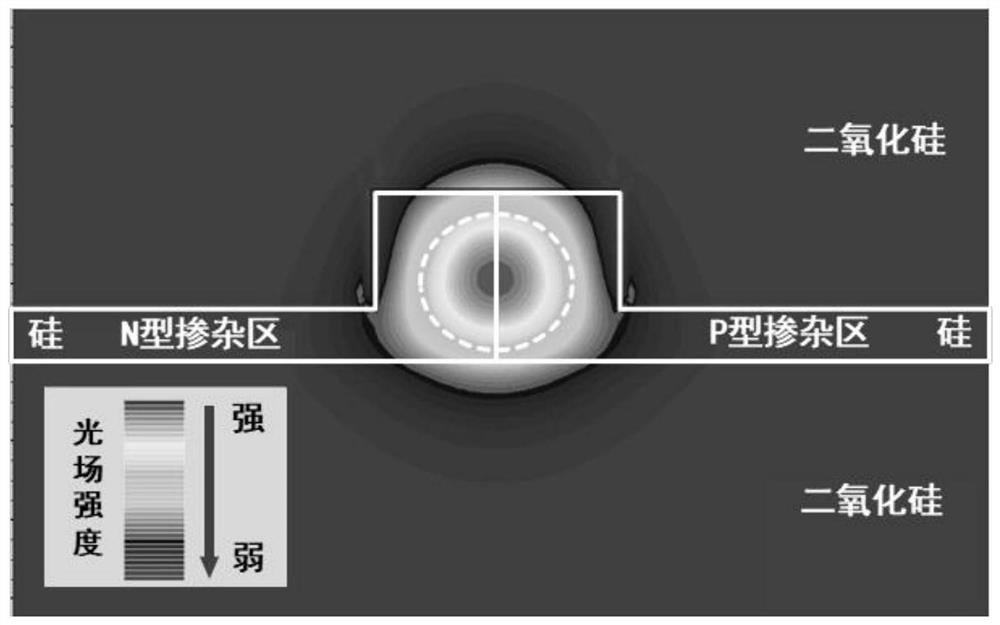

[0070] In the embodiment of the present invention, such as Figure 6 As shown, t...

Embodiment 3

[0091] The present invention provides two typical process conditions, which are used to illustrate the technical effect of the above-mentioned doping process; as Figure 7 As shown, recipe 1 is a process parameter designed for a ridge waveguide with a height of 220nm, and recipe 2 is another process parameter designed for a ridge waveguide with a height of 340nm; these two recipes are at different heights In the ridge waveguide, the doping concentration in the core region of the ridge waveguide is low and the doping concentration in the boundary region is high.

[0092] Such as Figure 7 As shown, since formula 2 is aimed at a ridge waveguide with a height of 340nm, and formula 1 is aimed at a ridge waveguide with a height of 220nm, the magnitudes of the first energy, the second energy and the third energy in formula 1 increase successively The size of the fourth energy, the fifth energy and the sixth energy in the formula 1 increases successively; the size of the first energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com