Manufacturing method of conformal antenna housing

A technology for conformal antennas and manufacturing methods, applied to antennas, antenna parts, radiation unit covers, etc., can solve problems such as poor system reliability and affecting communication system reliability, and achieve strong reliability, good designability, and quality stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0031] In order to illustrate the technical solutions of the embodiments of the present invention more clearly, the accompanying drawings of the embodiments will be briefly introduced below. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those of ordinary skill in the art Generally speaking, other drawings can also be obtained based on these drawings on the premise of not paying creative work.

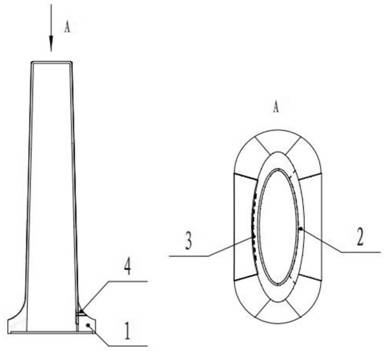

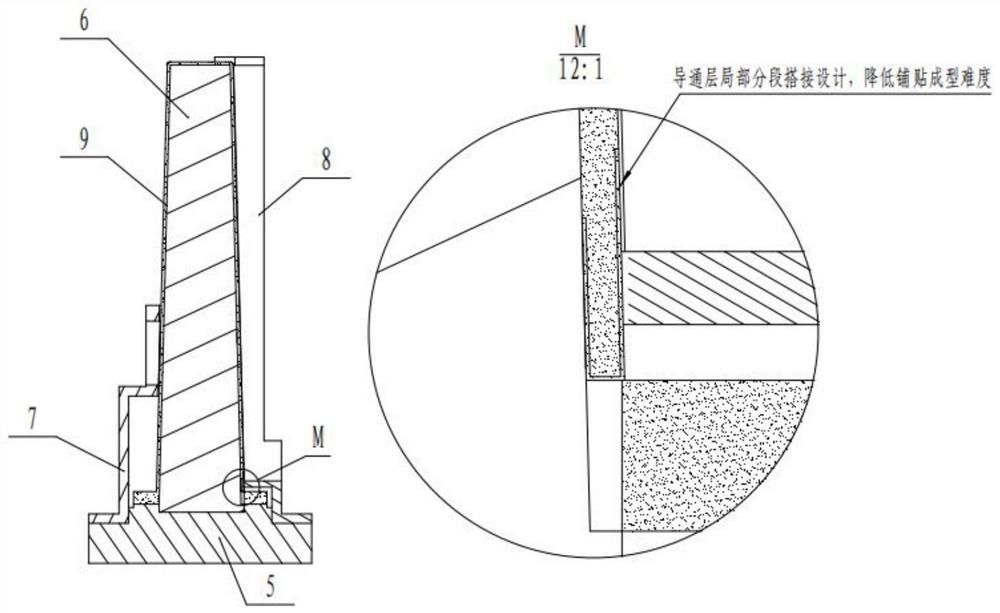

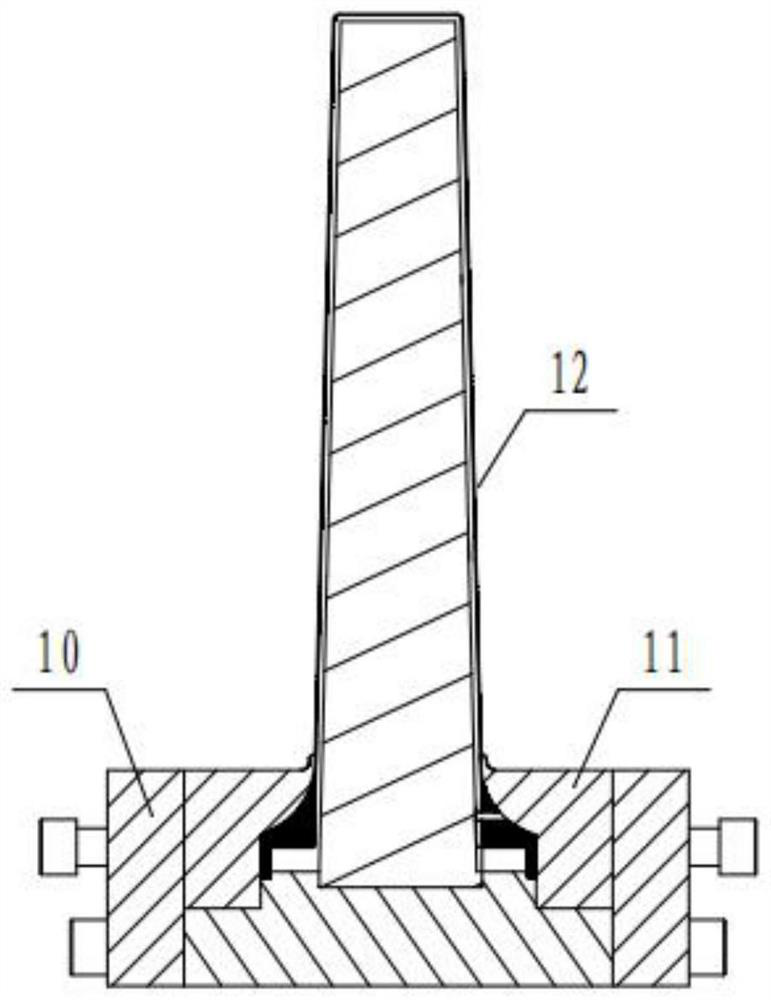

[0032] A method for manufacturing a conformal radome, using the processing and manufacturing technology, by accurately forming an electrically conductive layer and a reflective layer in the radome, a complex conformal antenna capable of transmitting and receiving directional beams can be prepared, and the antenna and cover body can be realized Integrated design and processing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com