Method for manufacturing reed-based specially-shaped container on basis of biomass adhesive

A container manufacturing and adhesive technology, which is applied in the chemical industry application field, can solve the problems of affecting the bonding performance, high silicon content in epidermal tissue, non-degradable application of products, etc., and achieves no formaldehyde release, good biodegradability, and appearance. good design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

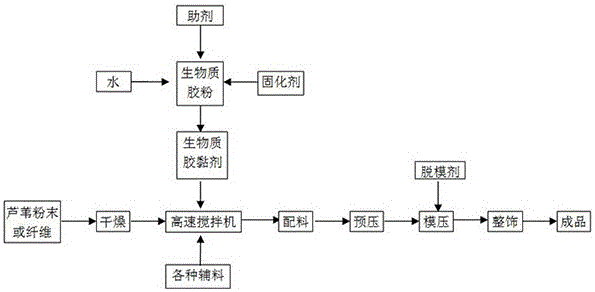

Image

Examples

preparation example Construction

[0016] (2) Preparation of reed-based special-shaped container substrate: add the reed-based raw material obtained in step (1) and auxiliary materials accounting for 1-10% of the total weight of the container into a high-speed mixer and stir evenly;

[0017] (3) Preparation of formaldehyde-free biomass adhesive: mix the main agent powder of biomass adhesive with water according to the mass ratio (50-80): 100 and stir evenly, add 3-30% of the total weight of the adhesive The curing agent, the appropriate amount of viscosity regulator and defoamer are mixed and stirred evenly to prepare the formaldehyde-free biomass adhesive;

[0018] (4) Slowly add the adhesive liquid obtained in step (3) into the high-speed mixer, the amount added is 10-50% of the total weight of the container, start the temperature rise control program, control the high-speed stirring temperature at 50-80°C, and mix Uniform and proper drying, control the final moisture content of the material at 15-25%;

[00...

Embodiment 1

[0026] Reed fiber is used as the main matrix material, and the original color reed fiber-based special-shaped container is molded and pressed. The weight of the container is 100g. The specific manufacturing process steps are divided into:

[0027] 1) Dry the reed fiber until the moisture content is 5%;

[0028] 2) Weigh 63g of reed fiber and 5g of starch into a high-speed mixer and stir evenly;

[0029] 3) Add 30g of biomass adhesive to 2g of curing agent, 3-5 drops of defoaming agent, etc. and mix evenly to prepare a liquid formaldehyde-free biomass adhesive;

[0030] 4) Slowly add the liquid adhesive to the mixture for glue mixing, start the heating and stirring control program, control the high-speed stirring temperature at 50-80°C, and control the final moisture content of the material at 20% through heat transfer and hot air volatilization;

[0031] 5) Pour the material mixed with biomass glue into the mold of the hot press molding machine coated with a release agent on ...

Embodiment 2

[0034] Reed sawdust powder is used as the main matrix raw material to mold and press natural color reed sawdust-based special-shaped containers. The total weight of the container is 100g. The specific manufacturing process steps are divided into:

[0035] 1) Dry the reed fiber until the moisture content is 5%;

[0036] 2) Weigh 68g of reed fiber, 3g of starch, and 2g of soybean powder and add them to a high-speed mixer and stir evenly;

[0037] 3) Add 25g of biomass adhesive to 2g of curing agent, 3-5 drops of defoaming agent, etc. and stir and mix evenly to obtain a liquid formaldehyde-free biomass adhesive;

[0038] 4) Slowly add the liquid adhesive to the mixture for glue mixing, start the heating and stirring control program, control the stirring temperature at 50-80°C, and control the final moisture content of the material at 20% through heat transfer and hot air volatilization;

[0039] 5) Pour the material mixed with biomass glue into the mold of the hot press molding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com