Bioabsorbable orthopedic implant material and preparation method thereof

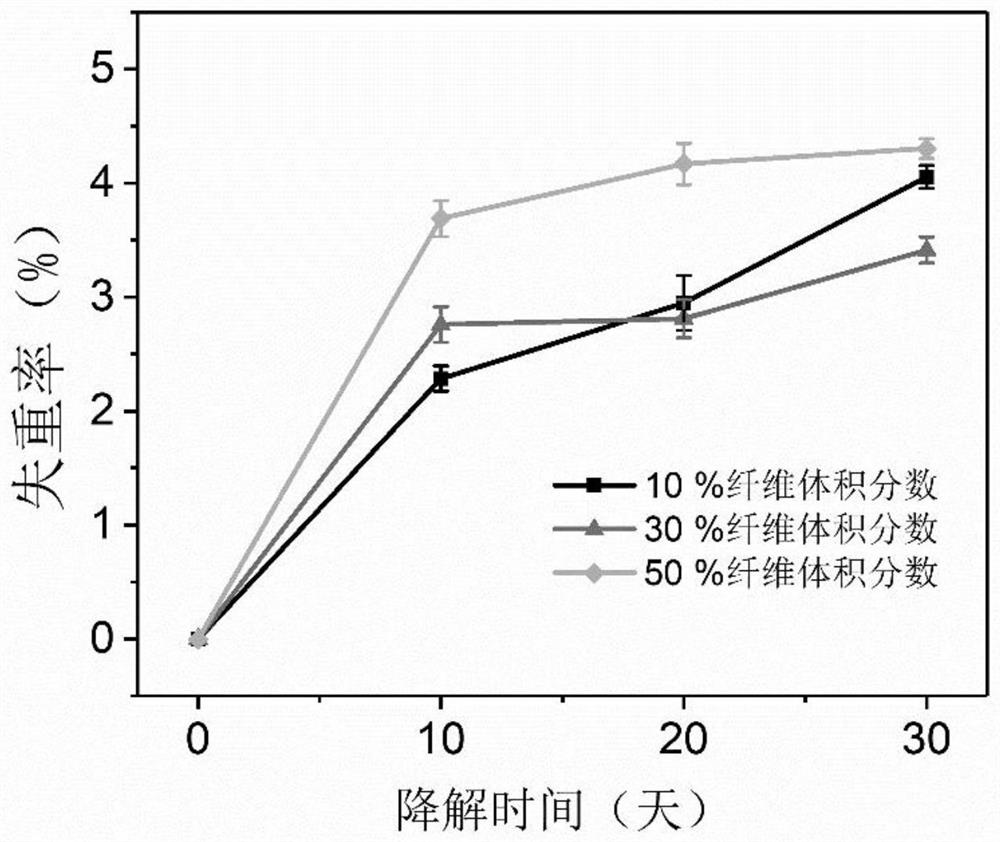

A technology for bioabsorption and implantation of materials, applied in the field of biomedical materials, can solve problems such as insufficient mechanical properties, and achieve the effects of good designability, good biocompatibility, and good damage resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

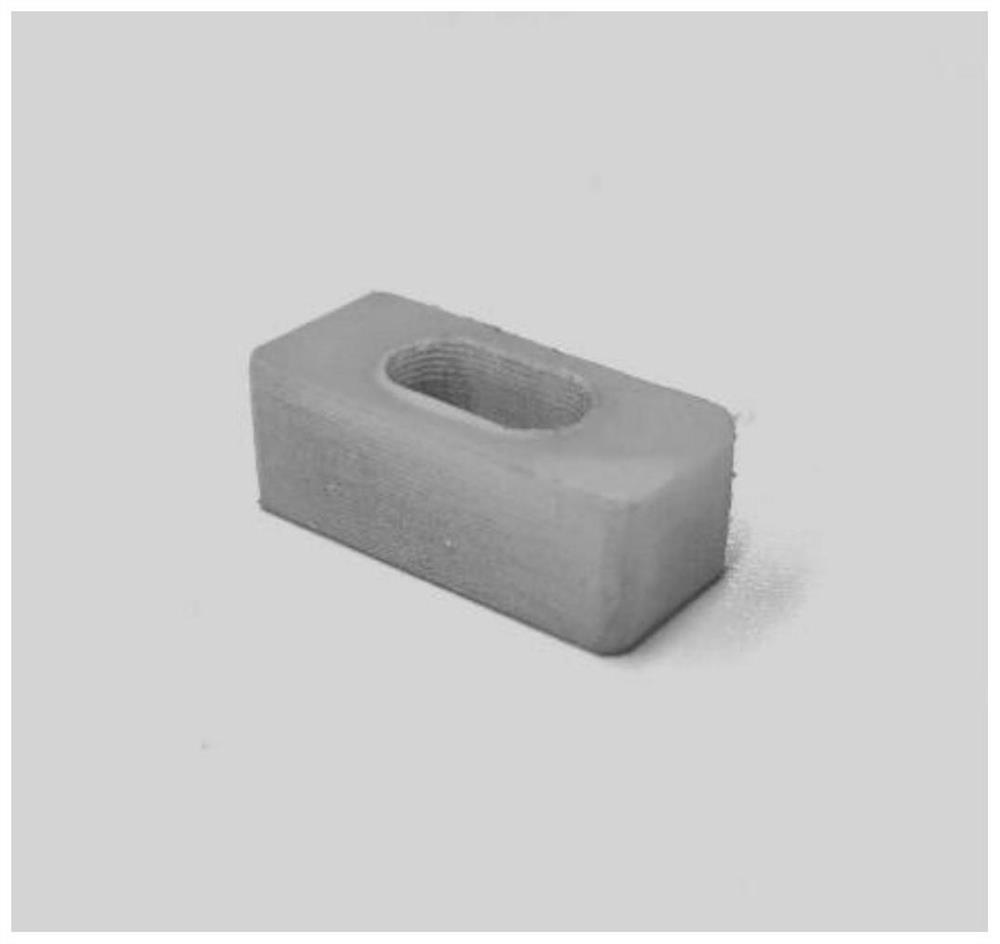

Image

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of the bioabsorbable orthopedic implant material described in the above technical solution, comprising the following steps:

[0044] The two-dimensional silk fiber fabric and the bioabsorbable polymer material film are laminated, and the first melting and the first prepressing are performed in sequence to obtain the bioabsorbable orthopedic implant material.

[0045] In the present invention, the thickness of the bioabsorbable polymer material film is preferably 0.07mm-0.18mm. In the present invention, before forming the bioabsorbable polymer material film, it is preferable to further include drying the bioabsorbable polymer material; the present invention does not limit the conditions for drying the bioabsorbable polymer material, It is sufficient as long as the bioabsorbable polymer material can be dried.

[0046] In the present invention, the two-dimensional silk fiber fabric is preferably pretreated before us...

Embodiment 1

[0079] A silk fiber-reinforced bioabsorbable orthopedic implant material: using silk fiber as a reinforcing phase and bioabsorbable polymer material polylactic acid as a matrix phase, it is prepared according to the following steps:

[0080] (1) Modification of silk fiber non-woven fabric

[0081] Dissolving γ-aminopropyltriethoxysilane in an ethanol solution is configured as a coupling agent solution, and in the coupling agent solution, the volume fraction of the coupling agent γ-aminopropyltriethoxysilane is 3%; Surface density is 60g / m 2 Put the artificial silk fiber non-woven fabric into the prepared coupling agent solution and let it stand at room temperature for 30 minutes; clean it with deionized water ultrasonically, soak it in medical alcohol for disinfection, and dry it in vacuum at 60°C for 24 hours to obtain improved Sexual silk fiber non-woven fabric.

[0082] (2) Preparation of prepreg

[0083] Polylactic acid (PLA) was vacuum-dried at 80°C for 24 hours and ma...

Embodiment 2

[0089] A silk fiber-reinforced bioabsorbable orthopedic implant material: using silk fiber as a reinforcement and bioabsorbable polymer material polycaprolactone as a matrix phase, it is prepared according to the following steps:

[0090] (1) Preparation of prepreg

[0091] Polycaprolactone (PCL) was vacuum-dried at 40°C for 48 hours and made into a film with a thickness of 0.7mm; the surface density was 90g / m 2 The two-dimensional plain weave fabric of mulberry silk was ultrasonically cleaned in deionized water, then soaked in medical alcohol for disinfection, and dried in vacuum at 60°C for 24 hours; a layer of two-dimensional plain weave silk fabric was placed in a rigid mold. Underneath the above layer of polycaprolactone film, preheat at 130°C for 5 minutes, apply a pressure of 5 MPa with a hot press, and keep the pressure for 3 minutes, so that the polycaprolactone is melted above the melting point and fully contacted and infiltrated with silk. After cooling, it is shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com