Polyurethane for solvent-free foot pad leather and preparation method thereof

A polyurethane, solvent-free technology, applied in the field of polyurethane, can solve problems such as environmental pollution, achieve the effects of environmental friendliness, increase the curing rate, and improve the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

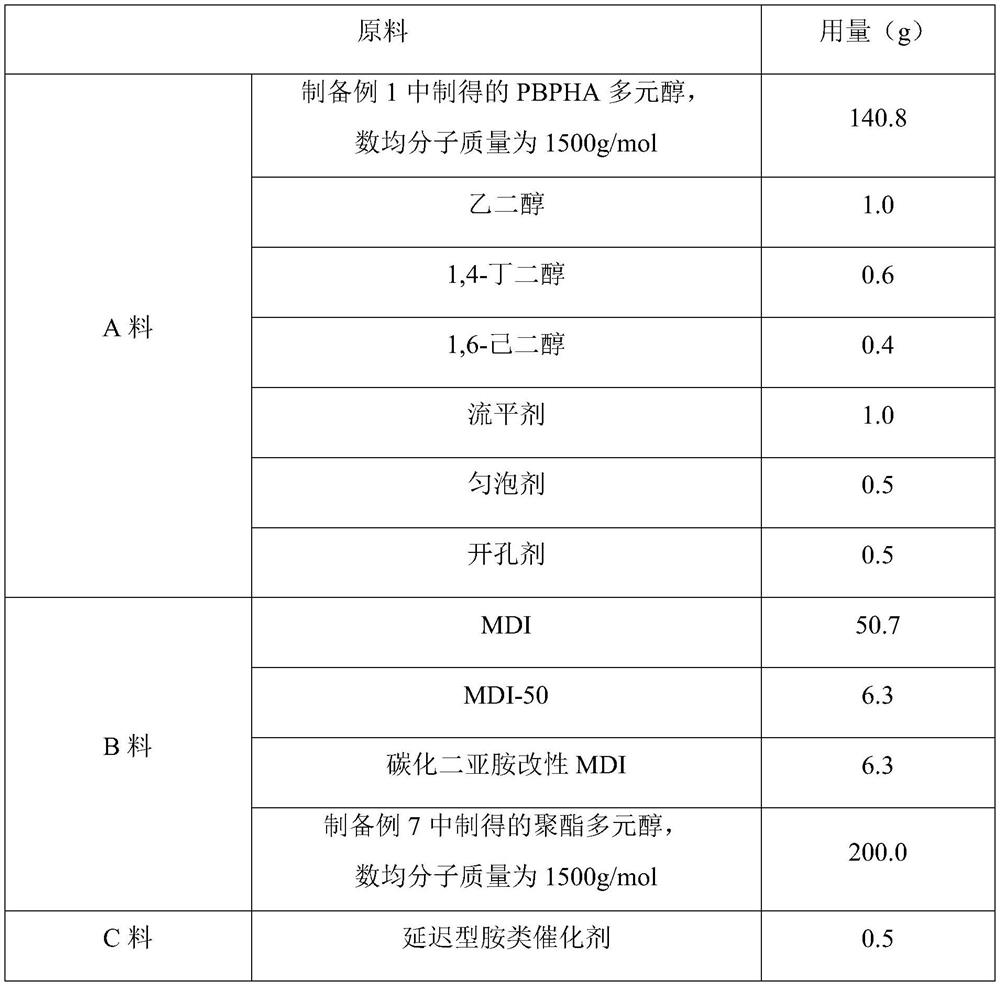

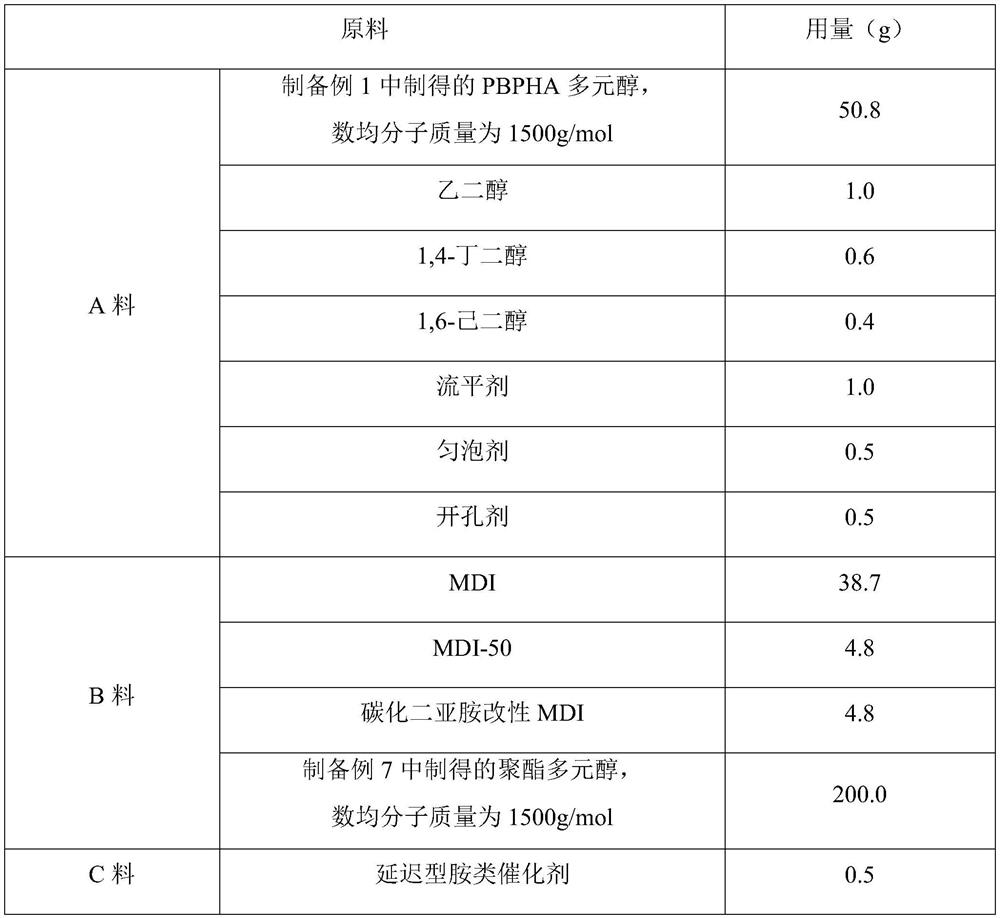

Examples

preparation example 1

[0047] The PBPHA polyol with a number-average molecular weight of 1500 is prepared from catalyst tetraisopropyl titanate, 1.10kg of composite polyol A and 1.900kg of 1,6-adipic acid, wherein composite polyol A and 1, The molar ratio of 6-adipic acid is 12:13, and the amount of catalyst-tetraisopropyl titanate is 40ppm of the total mass of composite polyol A and 1,6-adipic acid, and composite polyol A is composed of 1, 4-Butanediol, 1,2-propanediol, and 1,6-hexanediol are mixed in the reaction kettle in a mass ratio of 5:3:3.

[0048] The specific preparation method of PBPHA polyol is as follows: adding accurately metered composite polyol A, 1,6-adipic acid and tetraisopropyl titanate into a reaction kettle, mixing uniformly, and reacting at a temperature of 220 ° C for 1.3 hours Then, it is vacuumed step by step in the distillation tower (the degree of vacuum is gradually increased from 0.01Mpa to 0.098Mpa, when the vacuum reaches 0.098Mpa, the temperature at the top of the di...

preparation example 2

[0050] PBPHA polyol with a number-average molecular weight of 1500 is prepared from catalyst tetraisopropyl titanate, 1.19kg of composite polyol A and 1.900kg of 1,6-adipic acid, wherein composite polyol A and 1, The molar ratio of 6-adipic acid is 13:13, and the consumption of catalyst-tetraisopropyl titanate is 40ppm of the total mass of composite polyol A and 1,6-adipic acid, and composite polyol A is composed of 1, 4-Butanediol, 1,2-propanediol, and 1,6-hexanediol are mixed in the reaction kettle in a mass ratio of 5:3:3.

[0051]The specific preparation method of PBPHA polyol is as follows: adding accurately metered composite polyol A, 1,6-adipic acid and tetraisopropyl titanate into a reaction kettle, mixing uniformly, and reacting at a temperature of 220 ° C for 1.3 hours Then, it is vacuumed step by step in the distillation tower (the degree of vacuum is gradually increased from 0.01Mpa to 0.098Mpa, when the vacuum reaches 0.098Mpa, the temperature at the top of the di...

preparation example 3

[0053] The difference between this preparation example and preparation example 1 is that in this preparation example compound polyol A, 1,4-butanediol of the same mass is used to replace the 1,2-propanediol used to prepare compound polyol A in preparation 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com