Heat-conducting composite material and plate

A technology of thermally conductive composite material and heat storage material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

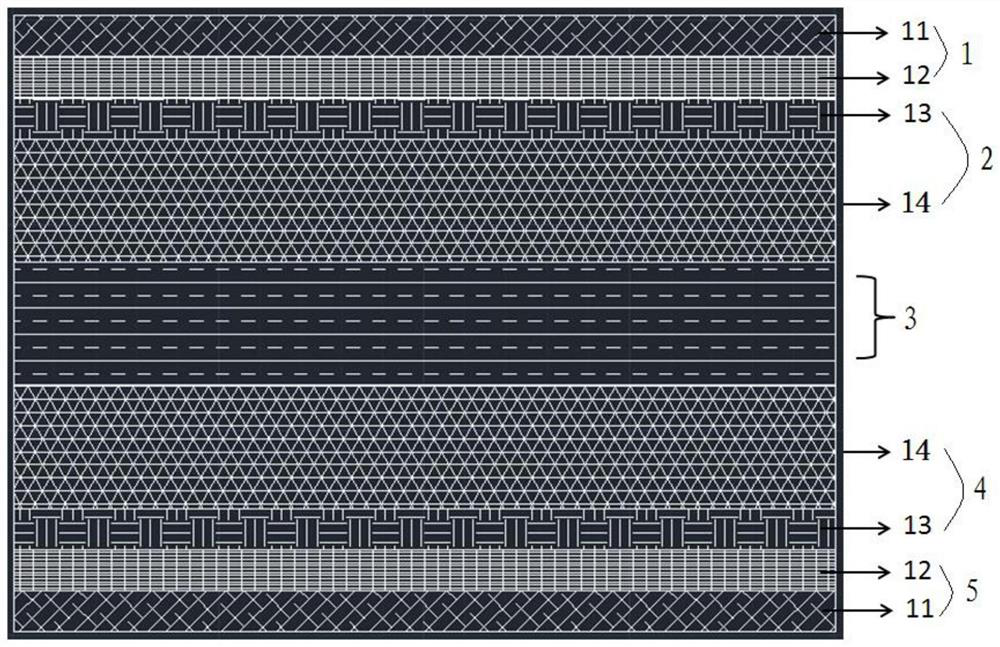

[0042] This embodiment provides a kind of melamine decorative board, the basic structure of the melamine decorative board is:

[0043] In this example, the main structure of the high-gloss melamine veneer resistant to cigarette burning is prepared as follows: figure 1 It is divided into five layers: from top to bottom: 1. Upper finish layer; 2. First functional layer; 3. Multi-layer plywood layer; 4. Second functional layer; 5. Lower finish layer;

[0044] The upper finishing layer and the lower finishing layer can be the same, including a glue layer 11 and a decorative material layer 12, and the decorative material layer 12 can be plain base paper or printed decorative paper, as described in this embodiment The gram weight of the decorative material layer 12 is 100g / m 2 , with a thickness of about 90 μm to 110 μm; the adhesive layer 11 can be an ordinary melamine resin layer, and the melamine resin used is purchased from Xinxiang Xinli Industrial Co., Ltd., MF50 melamine imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com