Production device of nanofiber yarn

A production device and nanofiber technology, applied in fiber processing, filament/thread forming, textile and papermaking, etc., can solve the problem of low yield of nanofibers, and achieve the effect of improving production utilization rate, improving practicability, and facilitating circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

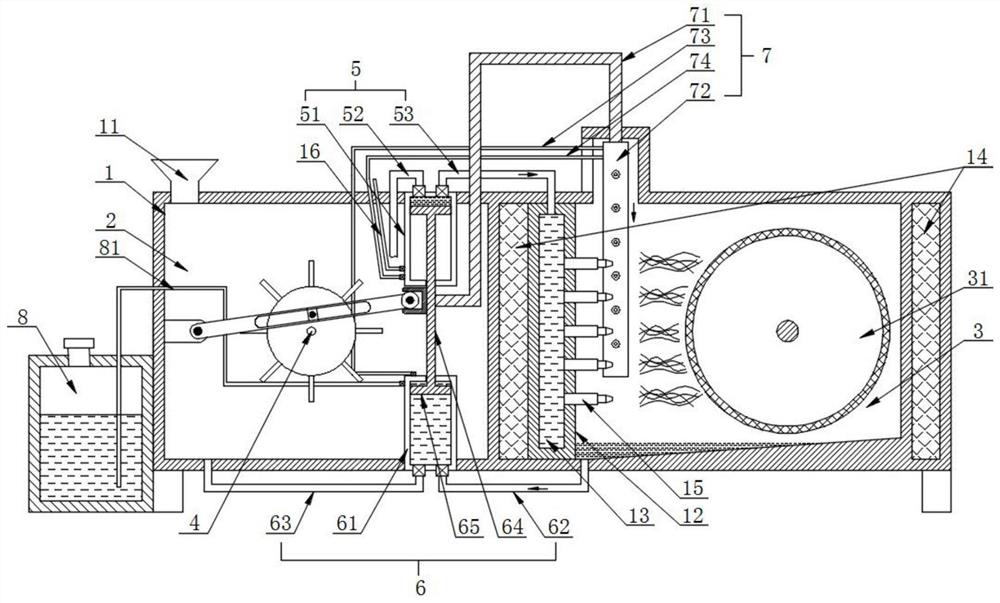

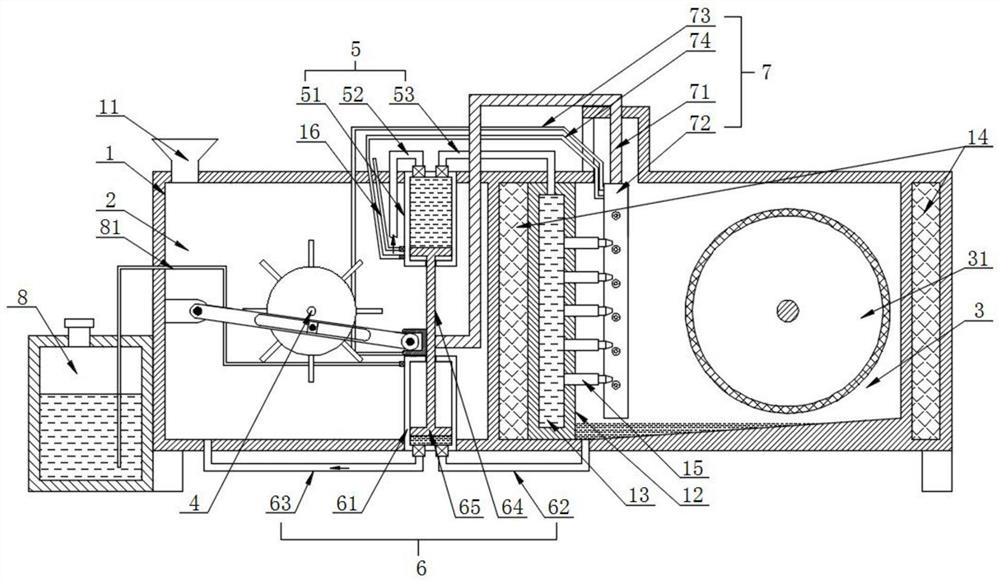

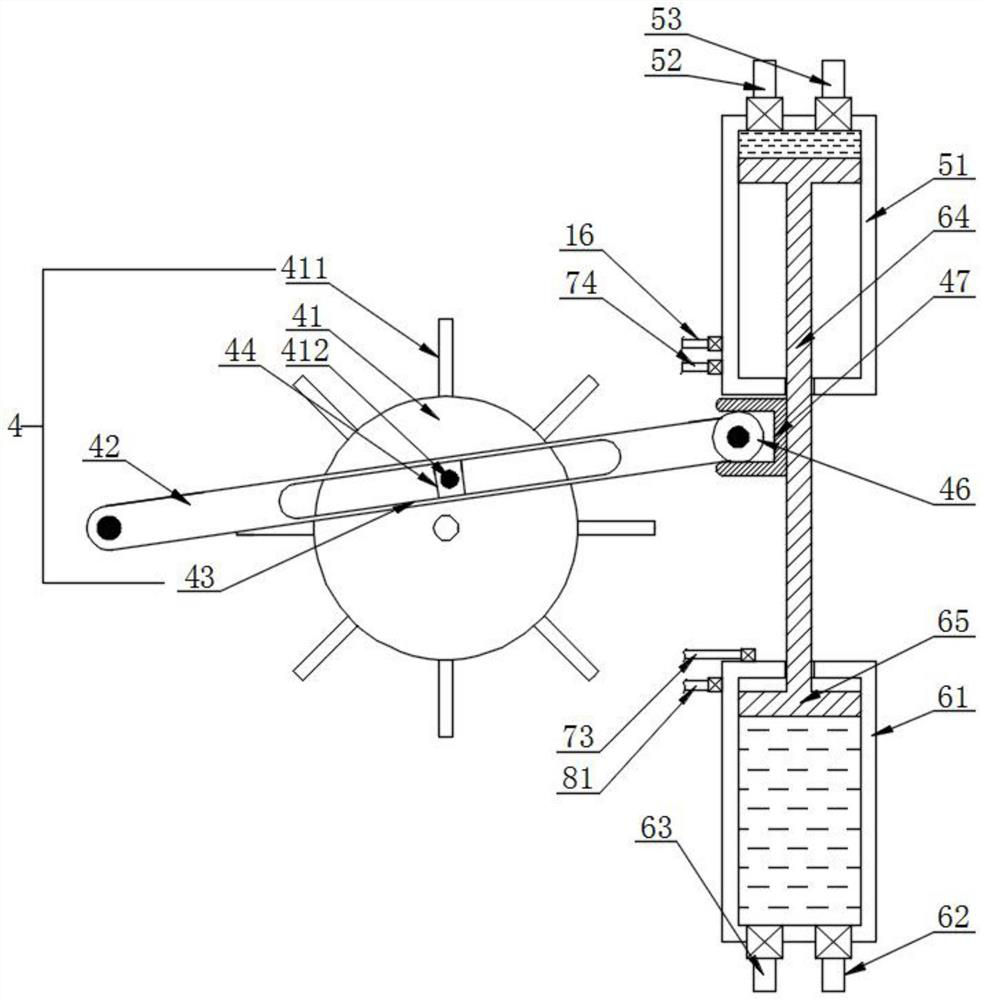

[0032] Refer to the attached Figure 1-4 , a production device for nanofiber yarns, comprising a box body 1, a partition 12 is fixedly embedded in the middle of the box body 1, and production chambers 2 symmetrically distributed with respect to the partition plate 12 are arranged in the box body 1 And the spinning chamber 3, the top side of the production chamber 2 is penetrated with a feed hopper 11 installed, and the inside of the spinning chamber 3 is equipped with a rotating drum roller blind 31 (the rotating drum roller blind 31 is driven by an external motor to rotate) , to facilitate the attachment of nanofibers), and both sides of the spinning chamber 3 are fixedly embedded with electrostatic plates 14, the inside of the partition 12 is provided with a liquid storage chamber 13, and the inner wall of one side of the spinning chamber 3 A plurality of sets of needle nozzles 15 are fixedly embedded on the top, and the needle nozzles 15 communicate with the inside of the l...

Embodiment 2

[0040] Refer to the attached Figure 1-4 , a production device for nanofiber yarns, comprising a box body 1, a partition 12 is fixedly embedded in the middle of the box body 1, and production chambers 2 symmetrically distributed with respect to the partition plate 12 are arranged in the box body 1 And the spinning cavity 3, the top side of the production cavity 2 is penetrated with a feed hopper 11 installed, the inside of the spinning cavity 3 is rotatably installed with a drum roller curtain 31, and the two sides of the spinning cavity 3 Both are fixedly embedded with electrostatic plates 14, and the inside of the partition 12 is provided with a liquid storage chamber 13, and a plurality of groups of needle nozzles 15 are fixedly embedded on one side of the spinning chamber 3, and the needle nozzles 15 It communicates with the inside of the liquid storage chamber 13, the inside of the production chamber 2 is provided with a stirring drive mechanism 4, and the top and bottom ...

Embodiment 3

[0047] Refer to the attached Figure 1-4 , a production device for nanofiber yarns, comprising a box body 1, a partition 12 is fixedly embedded in the middle of the box body 1, and production chambers 2 symmetrically distributed with respect to the partition plate 12 are arranged in the box body 1 And the spinning cavity 3, the top side of the production cavity 2 is penetrated with a feed hopper 11 installed, the inside of the spinning cavity 3 is rotatably installed with a drum roller curtain 31, and the two sides of the spinning cavity 3 Both are fixedly embedded with electrostatic plates 14, and the inside of the partition 12 is provided with a liquid storage chamber 13, and a plurality of groups of needle nozzles 15 are fixedly embedded on one side of the spinning chamber 3, and the needle nozzles 15 It communicates with the inside of the liquid storage chamber 13, the inside of the production chamber 2 is provided with a stirring drive mechanism 4, and the top and bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com