Nuclear power reactor optical fiber penetration assembly and preparation method and use method thereof

A penetration, nuclear power technology, applied in the field of nuclear power reactor optical fiber penetration and its preparation, to achieve the effects of small size, improved signal capacity, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment provides a nuclear power reactor optical fiber penetrating piece, such as figure 1 As shown, the optical fiber penetration member of this embodiment includes a metal shell; the metal shell is composed of an inner metal shell 1 and an outer metal shell 10, both of which are a cylindrical structure, and the inner metal shell 1 The inner metal shell 10 is connected to the inner wall of the containment (stack) through the inner fillet weld 13, the outer metal shell 10 is connected to the outer wall of the containment (stack) through the outer fillet weld 5, and the inner metal shell 1 and the outer metal shell 10 pass through a V-shaped groove 9 are welded together to form the metal housing of the optical fiber penetration.

[0057] The metal casing of the optical fiber penetration is used to achieve a reliable seal between the optical fiber penetration and the containment (stack) wall and accommodate all internal components.

[0058] The outer metal end pl...

Embodiment 2

[0064] This embodiment proposes a preparation method of the optical fiber penetration member proposed in the above embodiment 1, and the specific process is as follows:

[0065] Step 1, peel off a section of the protective sheath in the middle of an armored optical cable to expose the bare optical fiber to form a whole optical cable with a section of bare optical fiber in the middle, that is, form the outer armored optical cable 4, the bare optical fiber 6 and the inner armored optical cable 12 integrated structure.

[0066] Step 2, passing several armored optical cables manufactured according to Step 1 through the preset holes of the outer metal end plate 2 from the outside of the fiber penetration piece, so that the outer end of the bare optical fiber 6 is connected to the inner side of the outer metal end plate 2. The bottom of the groove is flush.

[0067] In step 3, the finished outer metal end plate 2 is placed inside the outer metal shell 10 , and the welding between t...

Embodiment 3

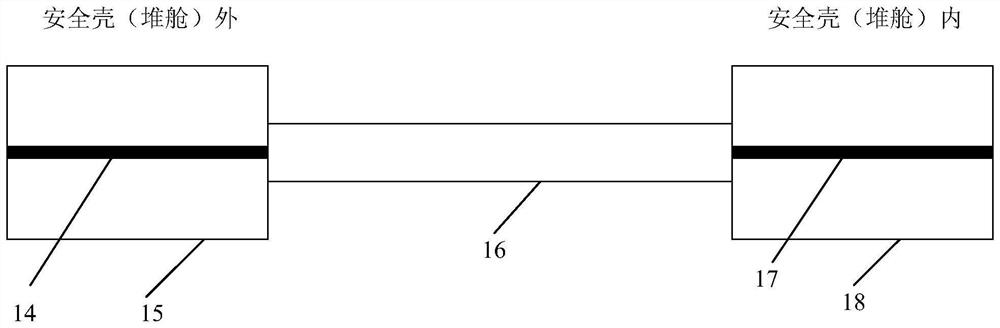

[0076] This embodiment adopts the optical fiber penetration piece proposed in the above embodiment 1 to realize the convenient connection of the armored optical cable at the construction site, such as figure 2 As shown, the specific implementation process is as follows:

[0077] An optical fiber penetration piece 16 is installed on the containment (stack) wall, and a reliable seal is achieved by means of welding.

[0078] An outer connection box 14 is arranged on the outside of the optical fiber penetration member 16, and an outer connection frame 15 is arranged inside the outer connection box 14, and the connection point between the outer armored optical cable 4 and the transmission optical cable outside the containment (stack) is arranged on the outer connection frame 15. The connection point provides mechanical protection, and the outer connection box 14 provides mechanical protection for the outer connection frame 15 and the connection point of the optical cable fixed the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com