Automatic batching production system and process for feed additives

A feed additive and automatic batching technology, which is applied in the general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of incapable of real-time control of the feeding ratio of materials, inability to monitor the batching of batching tanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

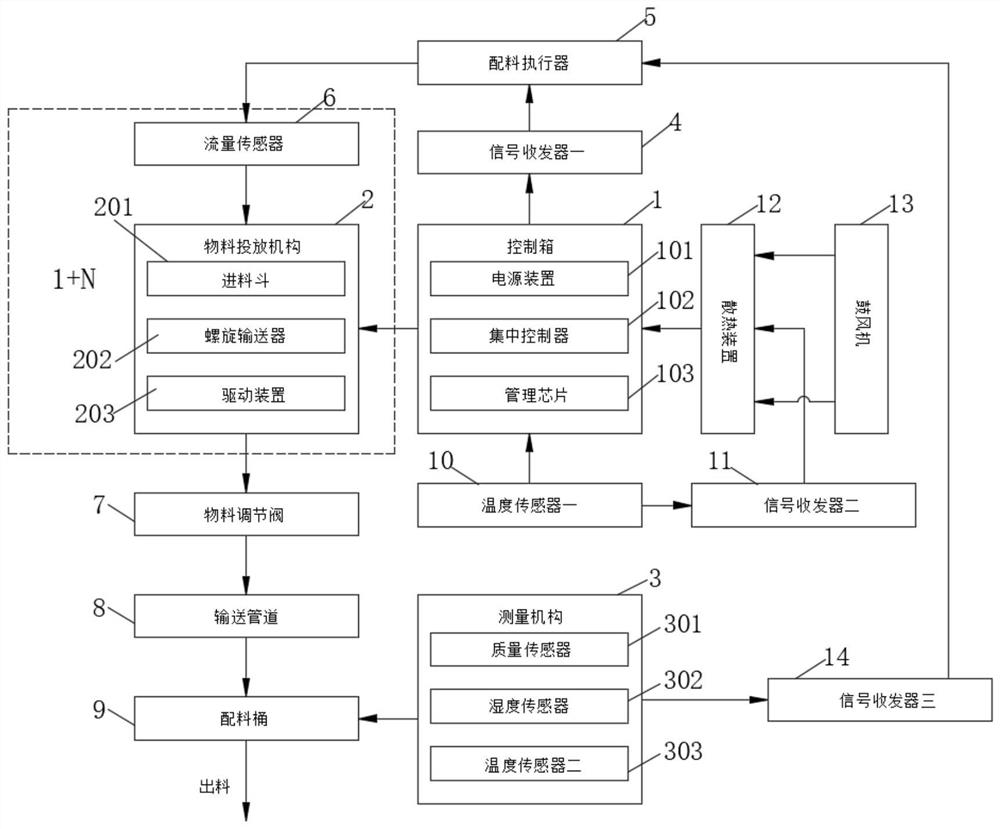

[0029] see figure 1 , the present invention provides a technical solution: a feed additive automatic batching production system, comprising a control box 1, a material feeding mechanism 2 and a measuring mechanism 3, the output end of the control box 1 is connected to the input end of the material feeding mechanism 2;

[0030] The output end of the material delivery mechanism 2 is connected with the batching barrel 9 pipelines;

[0031] The output end of the measuring mechanism 3 is connected to the input end signal of the batching barrel 9, the output end of the measuring mechanism 3 is connected to the input end signal of the batching actuator 5, and the output end of the batching actuator 5 is connected to the input end signal of the material feeding mechanism 2 ;

[0032] By setting the measuring mechanism 3, the quality sensor 301, the humidity sensor 302 and the temperature sensor 2 303 in the measuring mechanism 3 measure the various values of the ingredient barrel 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com