Video-based belt running state detection method

A technology of running status and detection method, which is applied in the direction of instruments, character and pattern recognition, computer parts, etc., can solve the problems of restricting the operation efficiency and dispatching automation level of the belt conveyor conveying system, consuming manpower and time, and being prone to negligence, mistakes and omissions, etc. , to achieve the effect of ensuring the safe operation of production, reducing the waste of materials and resources, and reducing negligence, errors and omissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

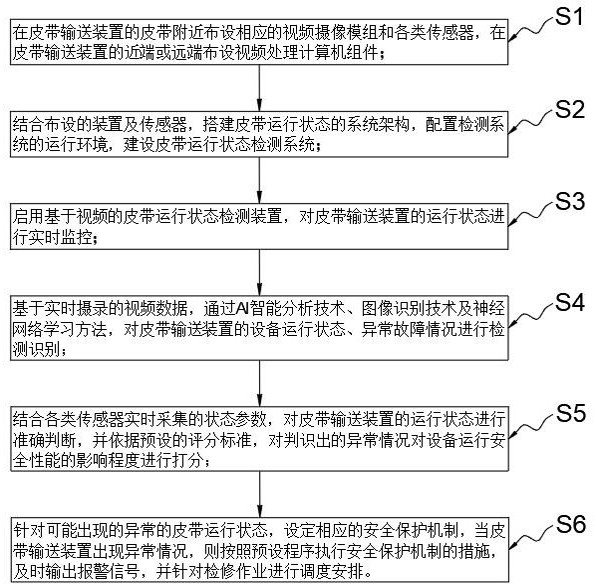

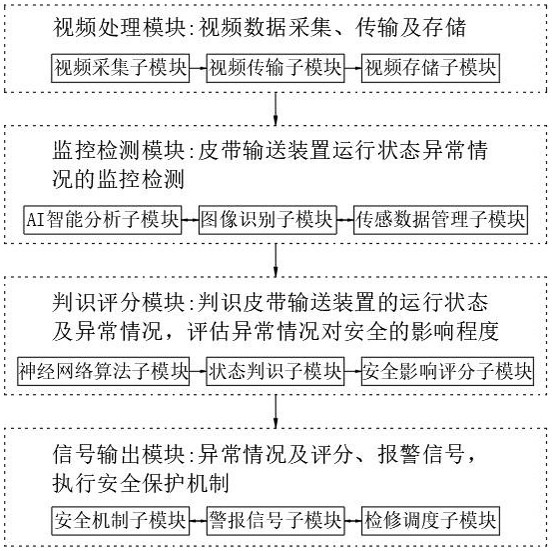

[0067] Such as Figure 1-Figure 3 As shown, the present embodiment provides a video-based belt running state detection method, including the following steps:

[0068] S1. Arrange corresponding video camera modules and various sensors near the belt of the belt conveyor, and arrange video processing computer components at the near or far end of the belt conveyor;

[0069] S2. Combining the installed devices and sensors, build a system architecture for the belt running status, configure the running environment of the detection system, and build a belt running status detection system;

[0070] S3. Enable the video-based belt running state detection device to monitor the running state of the belt conveying device in real time;

[0071] S4. Based on the video data recorded in real time, through AI intelligent analysis technology, image recognition technology and neural network learning method, detect and identify the equipment operation status and abnormal fault conditions of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com