High-voltage solid-state soft start all-in-one machine without power compensation

A technology of power compensation and soft start, applied in the direction of output power conversion devices, electrical components, current controllers, etc., can solve the problems of asynchronous turn-on and turn-off of thyristors, single function, thyristor damage, etc., to reduce pollution and Small inrush current, the effect of reducing the impact of the power grid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

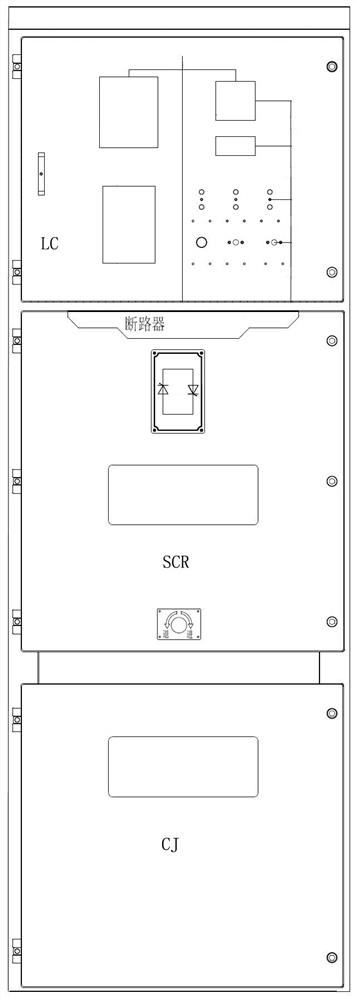

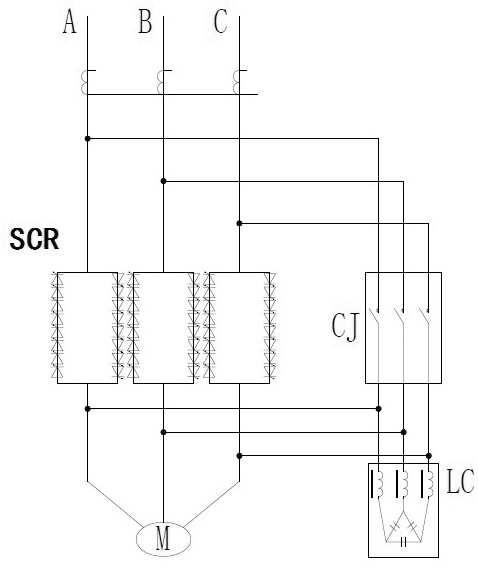

[0019] A high-voltage solid-state soft-start all-in-one machine without power compensation, including a thyristor SCR, a contactor CJ and a reactor LC arranged in the cabinet, the high-voltage power supply is connected to the motor M through the thyristor SCR, and the high-voltage power supply is connected across the contactor CJ is arranged in parallel with thyristor SCR and connected with reactor LC. The high-voltage circuit is composed of high-voltage thyristor components, valve body protection units, vacuum switch components, etc.; the control system is composed of thyristor trigger units, signal acquisition and protection components, and the trigger system connects the low-voltage control to the high-voltage part through optical fibers. Reliable isolation; system control and display interface form a human-computer interaction unit.

[0020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com