A mask for processing convex hemisphere of gyro motor and its processing method

A processing method and gyro motor technology, which are applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as the inability to guarantee the processing accuracy of convex hemispheres and the performance impact of gyro motors, and achieve improved mask rigidity and deburring effects. The effect of avoiding processing damage, avoiding deformation and loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood by those skilled in the art that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

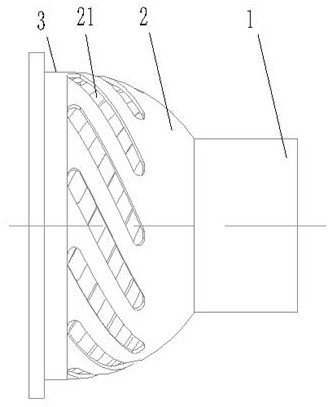

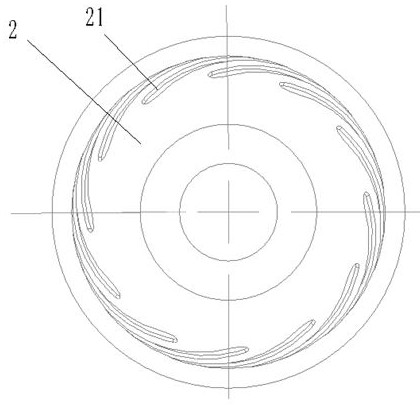

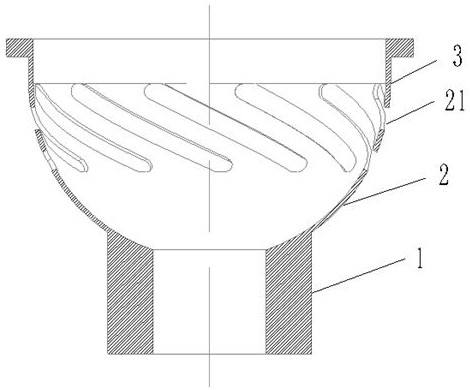

[0053] The difficulty of processing the logarithmic curve spiral groove of the convex hemisphere lies in the control of the groove depth. During ion etching, the ion beam is projected from one direction to the surface of the convex hemisphere in a straight line, and the convex hemisphere is driven by the tool to rotate around its axis at a certain speed. In this way, a plurality of spiral grooves evenly distributed on the entire spherical surface of the convex hemisphere can be etched. Based on this, the present invention provides a mask for processing the convex hemisphere of the gyro motor, which is used for processing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com