Intelligent ballistic automatic machining center for cone mirror part

A technology for automatic processing and parts, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of equipment price reduction, labor cost increase, high positioning accuracy requirements, etc., to improve work efficiency and save equipment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

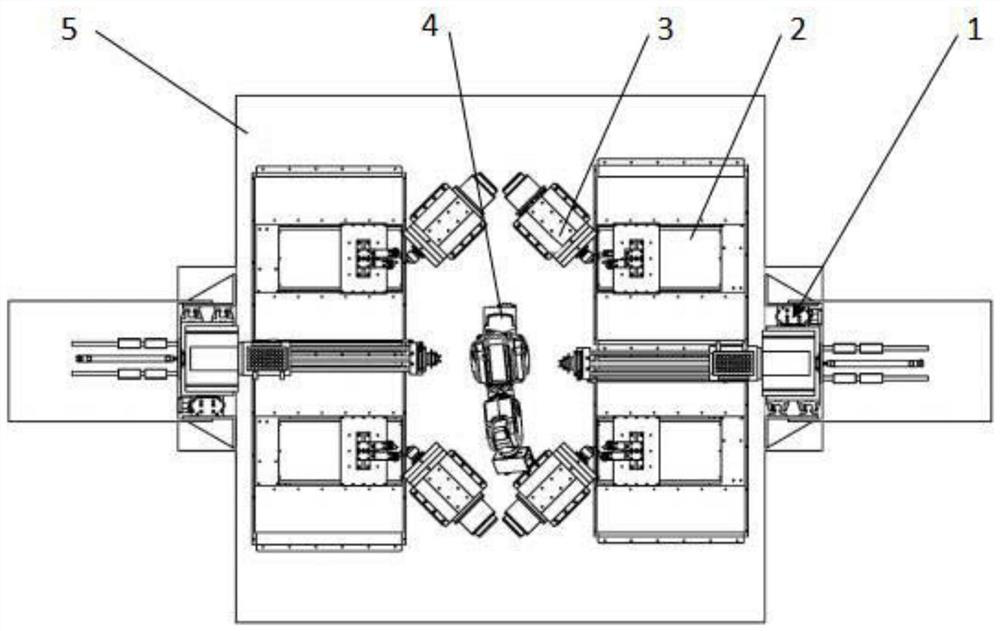

[0021] Such as Figure 1 ~ Figure 4 The shown intelligent ballistic automatic machining center for aconic mirror parts has a machine assembly 5, and a group of tray feeding systems 1 are symmetrically arranged at both ends of the machine assembly 5, and the feeding of the tray feeding system 1 The tool post system 2 is installed on the machine components 5 on both sides of the end respectively, the ultra-precision spindle 3 is provided at the tool position corresponding to the tool post system 2, and the robot handling system 4 is provided in the middle of the machine component 5 .

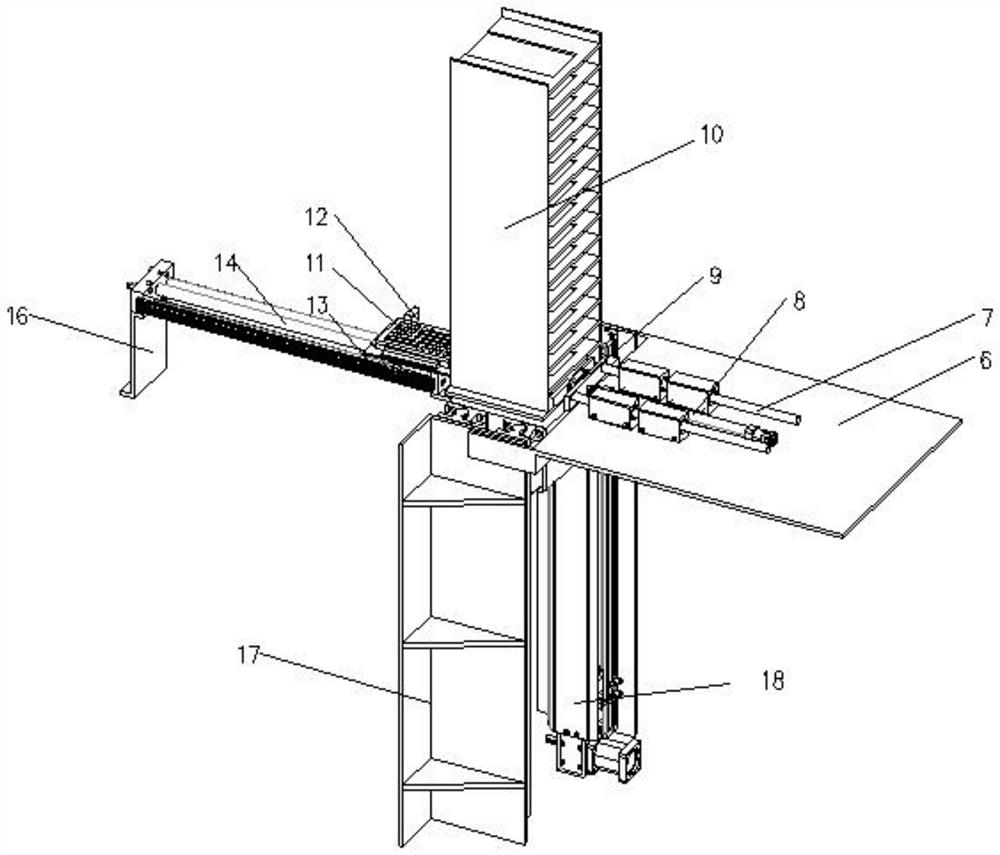

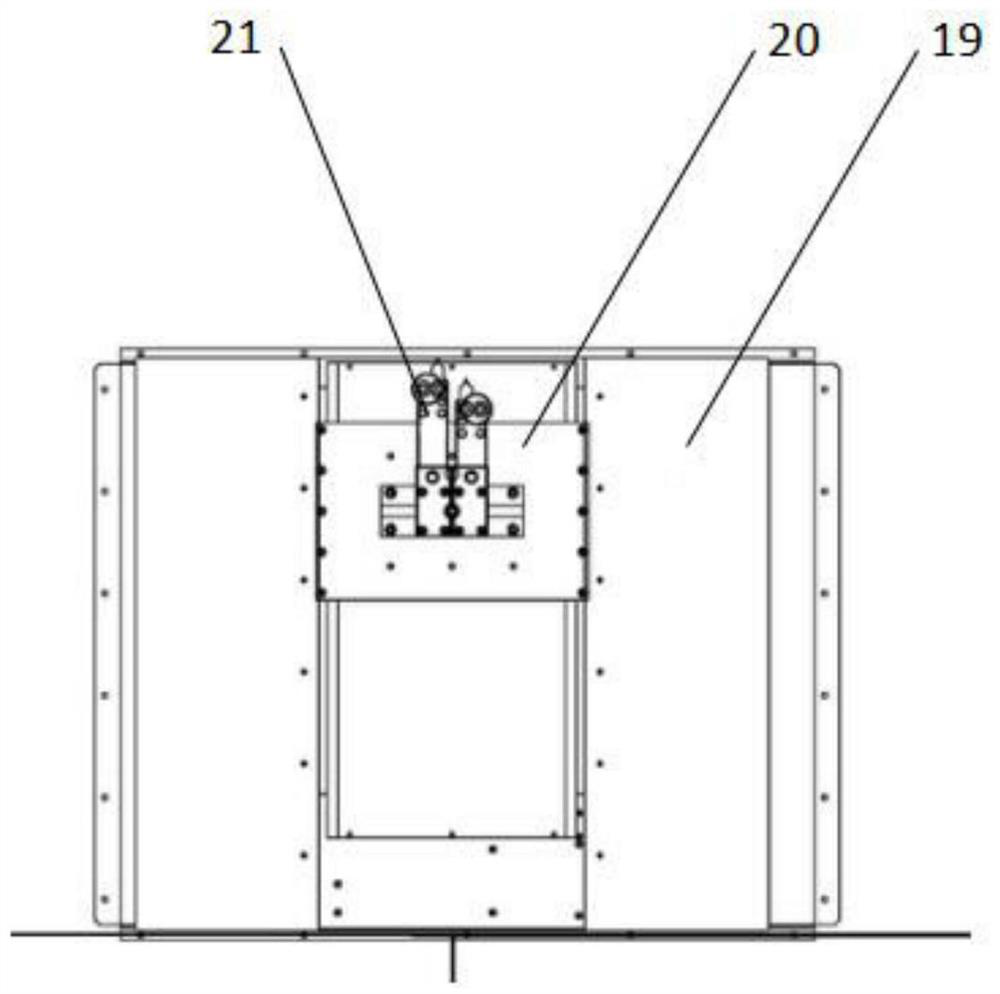

[0022] The pallet feeding system 1: includes a support frame 17 for laminati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com