Water conservancy gate load protection method and device

A technology for protection devices and gates, applied in measuring devices, water conservancy projects, coastline protection, etc., can solve problems such as short service life, high energy consumption, and easy failure, and achieve the effect of preventing misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

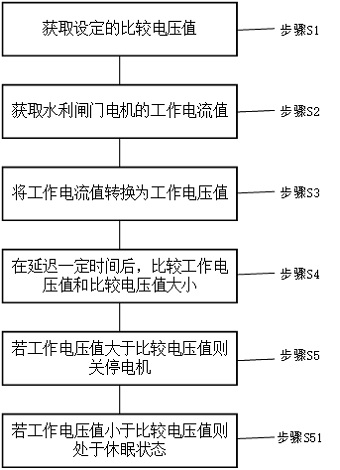

[0045] Please refer to figure 1 , figure 1 It is a flow chart of an optional implementation of the load protection method for water conservancy gates provided by the present invention. This embodiment provides a load protection method for water conservancy gates, including the following steps: Step S1: Obtain the set comparison voltage value; Step S2 : Obtain the working current value of the water conservancy gate motor; Step S3: Convert the working current value into a working voltage value; Step S4: Perform a delay comparison, compare the working voltage value and the comparison voltage value; Step S5: If the working voltage value is greater than the comparison voltage value, the motor is turned off. In some optional implementation manners, step S5 further includes: step S51: if the operating voltage value is less than the comparison voltage value, enter a dormant state, which reduces execution redundancy.

[0046] The gate load protection instrument is a device used to sc...

Embodiment 2

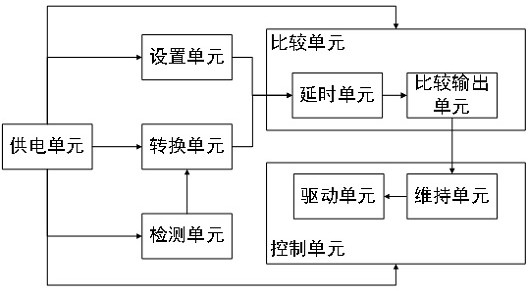

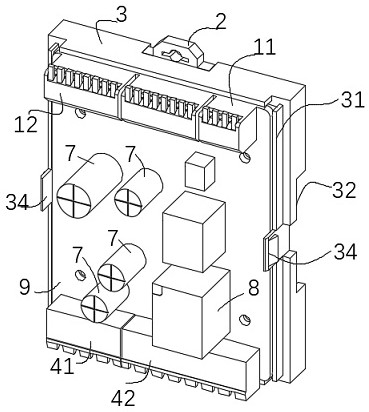

[0053] The realization of the technical effect of the present invention is described below from a more specific and detailed load protection device, please refer to figure 2 and image 3 , figure 2 It is a functional block diagram of an optional embodiment of the load protection device for water conservancy gates provided by the present invention; image 3 It is a structural schematic diagram of an optional embodiment of the load protection device for a water conservancy gate provided by the present invention. This embodiment provides a load protection device for a water conservancy gate, including: a detection unit and a conversion unit, the detection unit is electrically connected to the conversion unit, the detection unit is configured to: obtain the working current value of the water conservancy gate motor, and the conversion unit is configured to: The working current value is converted into a working voltage value; the setting unit is electrically connected to the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com