Cetrorelix acetate for injection and preparation method thereof

A technology of cetrorelix acetate and cetrorelix, applied in the direction of non-active ingredient medical preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve problems such as difficulty in long-term storage, and achieve improved preservation Time, improve temperature resistance, reduce the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

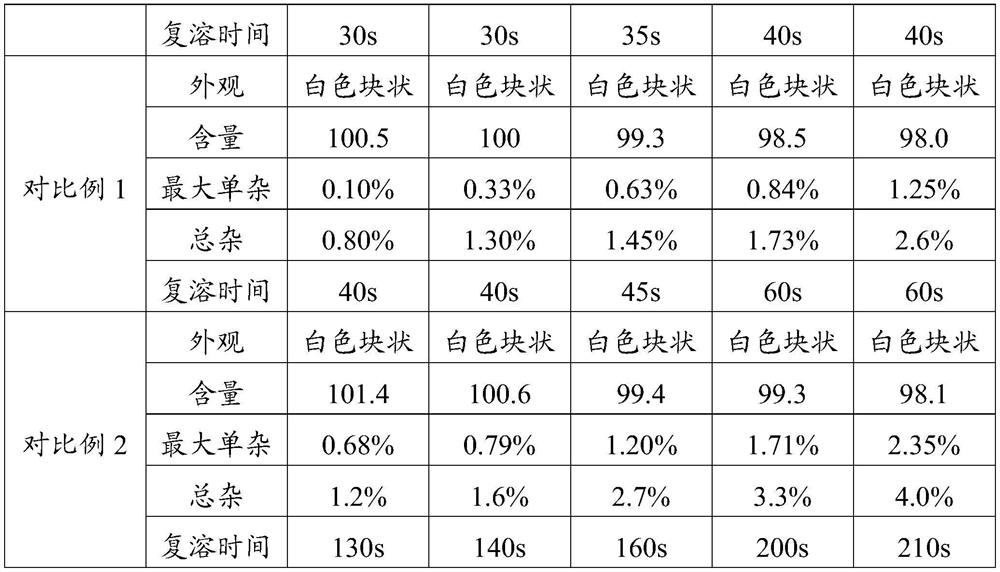

Examples

preparation example Construction

[0009] The preparation method of cetrorelix acetate for injection comprises the steps of adding hydroxyethyl starch and mannitol into the cetrorelix acetate solution and mixing with ultrasonic wave to obtain solution A;

[0010] And the step of spraying and freeze-drying solution A to obtain cetrorelix acetate for injection.

[0011] Among them, by using ultrasonic wave to mix solution A obtained by mixing hydroxyethyl starch, mannitol and cetrorelix acetate, it can effectively promote the formation of stable colloidal dispersion of hydroxyethyl starch in solution A, and promote the formation of cetrorelix acetate. grams uniformly dispersed in the colloidal dispersion. The mixing and spray freeze-drying are preferably carried out under the protection of nitrogen gas. In order to prevent the hydroxyethyl starch from swelling during mixing or after opening, in one embodiment, an anti-swelling agent, preferably sodium chloride, can also be added during mixing.

[0012] Cetrorel...

Embodiment 1

[0022] The preparation method of cetrorelix acetate for injection comprises the steps:

[0023] S1. Dissolve 3 g of cetrorelix in 30% acetic acid and dilute to volume with water for injection to obtain a 0.3% cetrorelix acetate solution;

[0024] S2. Add hydroxyethyl starch 200 / 0.5, mannitol and 2 g of sodium chloride into the cetrorelix acetate solution, and obtain solution A after mixing with ultrasonic waves;

[0025] Wherein, the mass ratio of hydroxyethyl starch and cetrorelix acetate is 0.4:1, and the mass ratio of cetrorelix acetate and mannitol is 1:300;

[0026] S3. Atomize solution A at 1.35 bar, pre-freeze the atomized particles at -40°C for 2 hours, freeze-dry for the first time at -30~-25°C, refreeze at -35°C for 1 hour, - Freeze-drying for the second time at 30-25°C, freeze-drying for the third time at 25-30°C, and freeze-drying at a heating rate of 5°C / min to obtain cetrorelix acetate freeze-dried granules;

[0027] S4, bottling the cetrorelix acetate freeze-d...

Embodiment 2

[0029] The difference between the preparation method of cetrorelix acetate for injection and Example 1 is that the concentration of the cetrorelix acetate solution is 0.4%, and the hydroxyethyl starch is selected from hydroxyethyl starch 130 / 0.4, hydroxyethyl starch The mass ratio of starch to cetrorelix acetate is 0.2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com