Sulfuryl fluoride reaction device

A technology of sulfuryl fluoride reaction and reaction chamber, which is applied in the direction of sulfuryl fluoride, sulfur and halogen compounds, chemical instruments and methods, etc., can solve the problems of the influence of activated carbon activity, the influence of sulfuryl fluoride yield, and the carrying of particle impurities, etc., to achieve Ensure quality and yield, avoid excessive temperature fluctuations, and ensure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

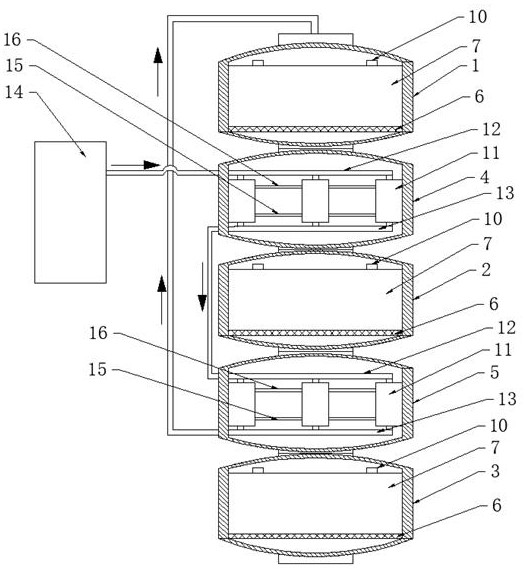

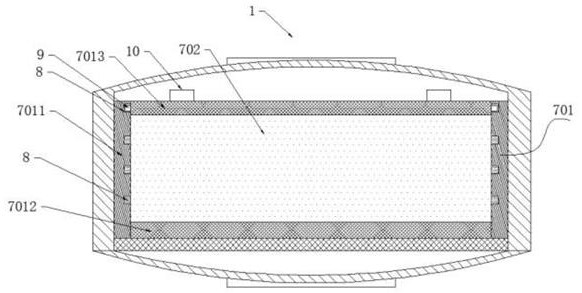

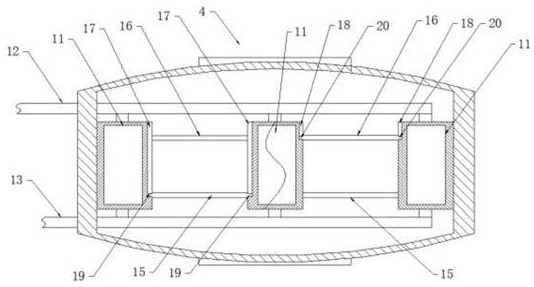

[0034] Such as Figure 1-Figure 4 As shown, the present invention provides a sulfuryl fluoride reaction device, comprising a reaction chamber and a heat exchange chamber;

[0035] There are three reaction chambers, namely reaction chamber A1, reaction chamber B2 and reaction chamber C3;

[0036] There are two heat exchange chambers, namely heat exchange chamber A4 and heat exchange chamber B5;

[0037] The gas inlet of the heat exchange chamber A4 is connected to the gas outlet of the reaction chamber A1, the gas outlet of the heat exchange chamber A4 is connected to the gas inlet of the reaction chamber B2; the gas inlet of the heat exchange chamber B5 is connected to the gas outlet of the reaction chamber B2, and the heat exchange The gas outlet of chamber B5 is connected with the gas inlet of reaction chamber C3;

[0038]The mixed raw gas enters the reaction device from the gas inlet of the reaction chamber A1, and enters the heat exchange chamber A4 to exchange heat afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com