VCM (voice coil motor) dispensing and curing device

A curing device and dispensing technology, applied in electromechanical devices, devices for coating liquid on surfaces, manufacturing of motor generators, etc., can solve the problems of long curing time of colloid and low production efficiency of dispensing process, and shorten curing time. , Good curing effect and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

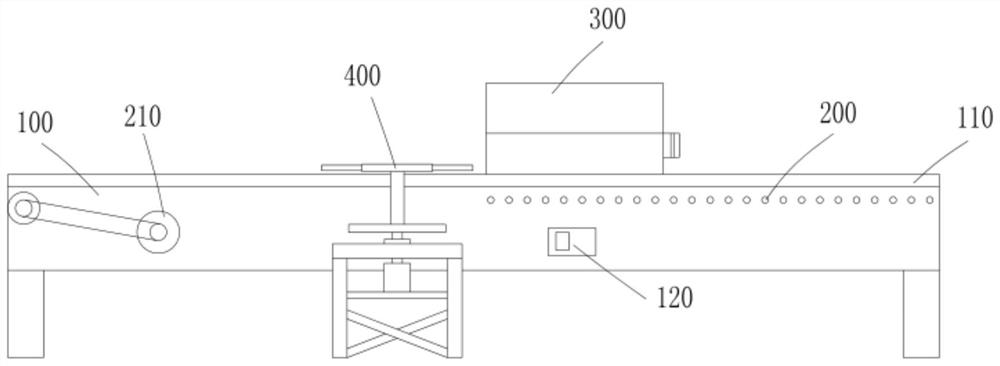

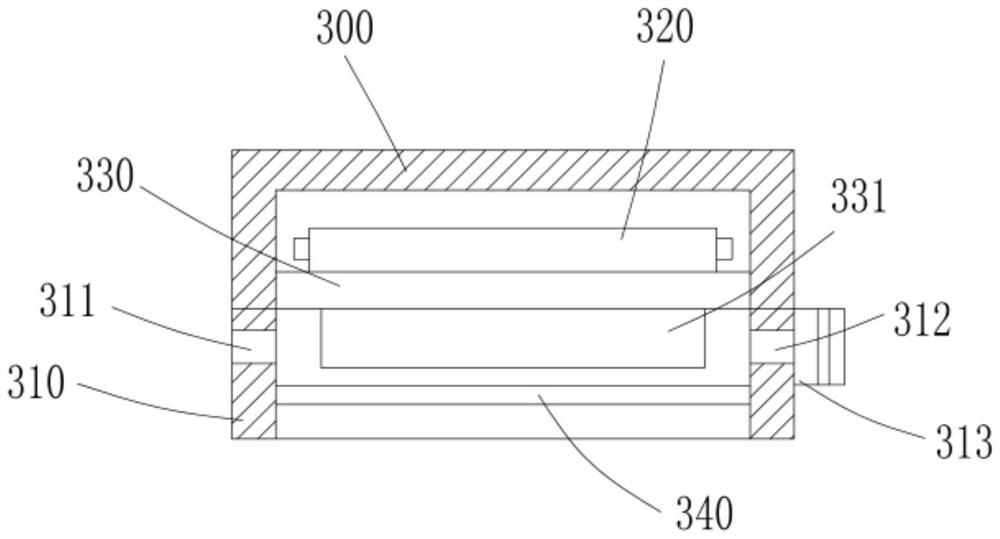

[0030] The present invention provides a technical solution: a VCM motor dispensing and curing device, including a workbench 100, the workbench 100 is provided with a conveying mechanism 200 for conveying a jig 500 with products, and the two sides of the upper end of the workbench 100 are respectively arranged A fence 110 is provided; a top plate 300 is arranged above the workbench 100, a frame plate 310 is provided at the bottom of the top plate 300, and the top plate 300 has a cavity, and a heating element 320 is arranged in the cavity, and the top plate 300 is under the heating element 320 A heat conduction plate 330 is arranged on the side, and several sets of partitions 331 are arranged on the lower side of the heat conduction plate 330. The adjacent two sets of partitions 331 form an air flow channel. One end of the frame plate 310 is provided with an air inlet 311, and the other end is provided with an air outlet 312. , the air inlet 311 and the air outlet 312 are in comm...

Embodiment 2

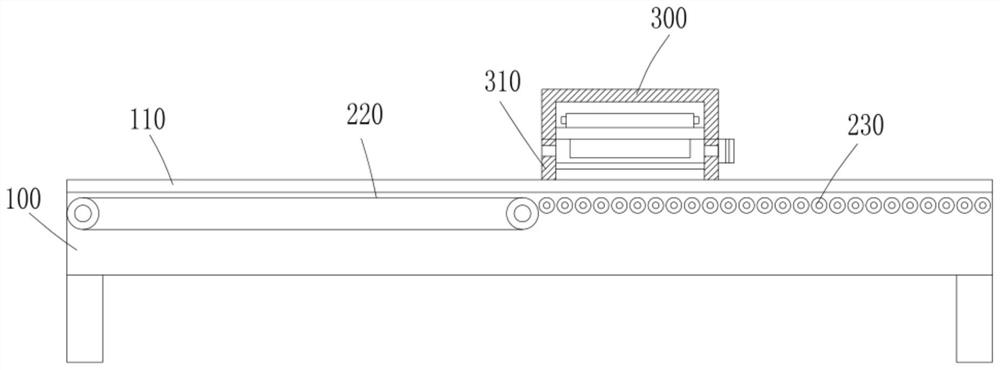

[0033]On the basis of Embodiment 1, the conveying mechanism 200 includes a first conveyor belt set 220, a second feed roller set 230 and a first driving power supply 210, and the first conveyor belt set 220 and the second feed roller set 230 are along the working table 100. The jig 500 is butted in the discharge direction, the top plate 300 is located above the feed end of the second feed roller set 230, the first drive source is used to drive the first conveyor belt set 220 to rotate at intervals; the feed assembly 400 is located on the first conveyor belt set 220 one side of the discharge end; the feeding assembly 400 includes a fixed frame 410, an adjustment disc 420, a rotating disc 430 and a second drive source 440, the fixed frame 410 is arranged on one side of the workbench 100, and the top is connected with a support plate 411 and an adjustment disc 420 The rotation is arranged on the upper end of the support plate 411, and the rotating disk 430 is connected with the ad...

Embodiment 3

[0036] On the basis of Embodiment 1 or Embodiment 2, the jig 500 is circular, two groups of sliders 510 are arranged symmetrically on the upper end of the jig 500, and the inner walls on both sides of the frame plate 310 are respectively provided with backing plates 340, each set of backing plates 340 A set of chute is arranged on the lower side, and the slide block 510 corresponds to the chute one by one, and can be slidably connected; the outer wall of the air outlet 312 is equipped with an induced fan 313 .

[0037] Specifically, the induced fan 313 allows the airflow to enter the airflow passage through the air inlet 311, and the airflow is heated in the airflow passage to solidify the product dispensing, and is discharged from the air outlet 312 smoothly. The block 510 is slidingly connected with the chute, which acts as an airtight barrier to the two sides of the jig 500, so that the heated airflow is not easy to leak from the two sides, and effectively improves the curin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap