Polluted soil in-situ chemical barrier material and preparation and application thereof

A technology of polluted soil and barrier materials, applied in the restoration of polluted soil, etc., can solve the problems of reducing the content of pollution factors, restricting construction, pollution exposure, etc., and achieve the effects of long-lasting performance, convenient material acquisition, and multiple functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation of embodiment 1 polluted site chemical barrier layer material

[0047] This example is aimed at the application of in-situ barrier control of heavy metal and organic pollutant compound polluted soil:

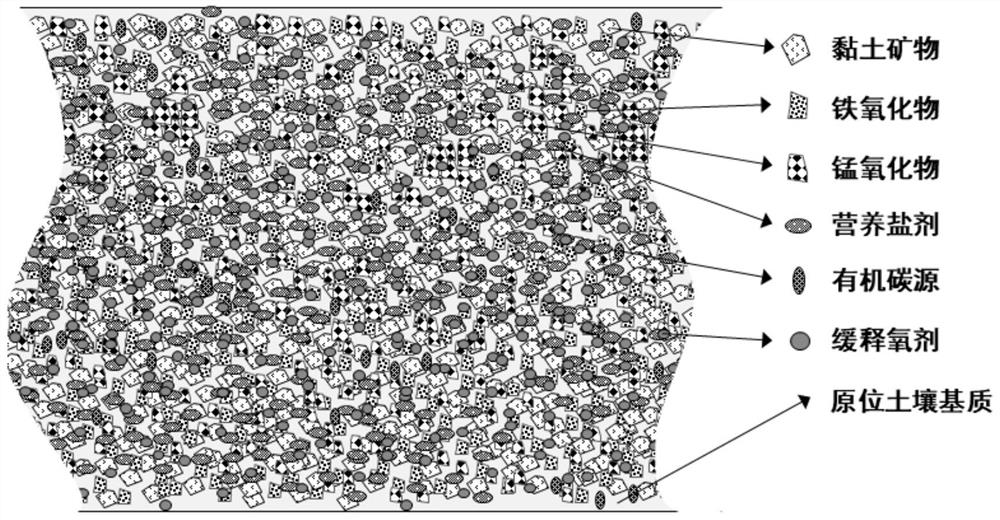

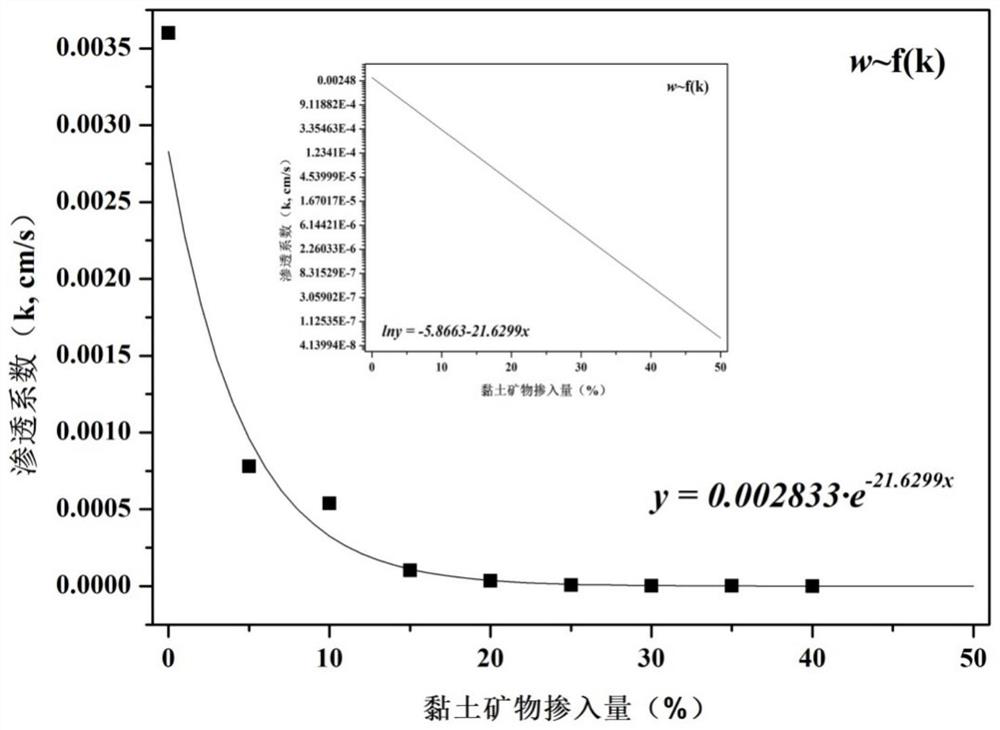

[0048] Accordingly, the chemical barrier material is composed of "in-situ soil + clay mineral + heavy metal stabilization active material + biostimulation active material". The schematic diagram of the chemical barrier material is as follows: figure 1 As shown, the composition of each component of the material is shown in Table 1.

[0049] 1) Preparation of chemical barrier materials

[0050] First, the in-situ soil was used as the matrix of the chemical barrier material, and the in-situ soil was excavated from a contaminated site of a chemical plant in the north. The soil pollution in the site was characterized by heavy metal arsenic exceeding the "Soil Environmental Quality Construction Land Soil Pollution Risk Control Standard" (GB 36600-2018), the sc...

Embodiment 2

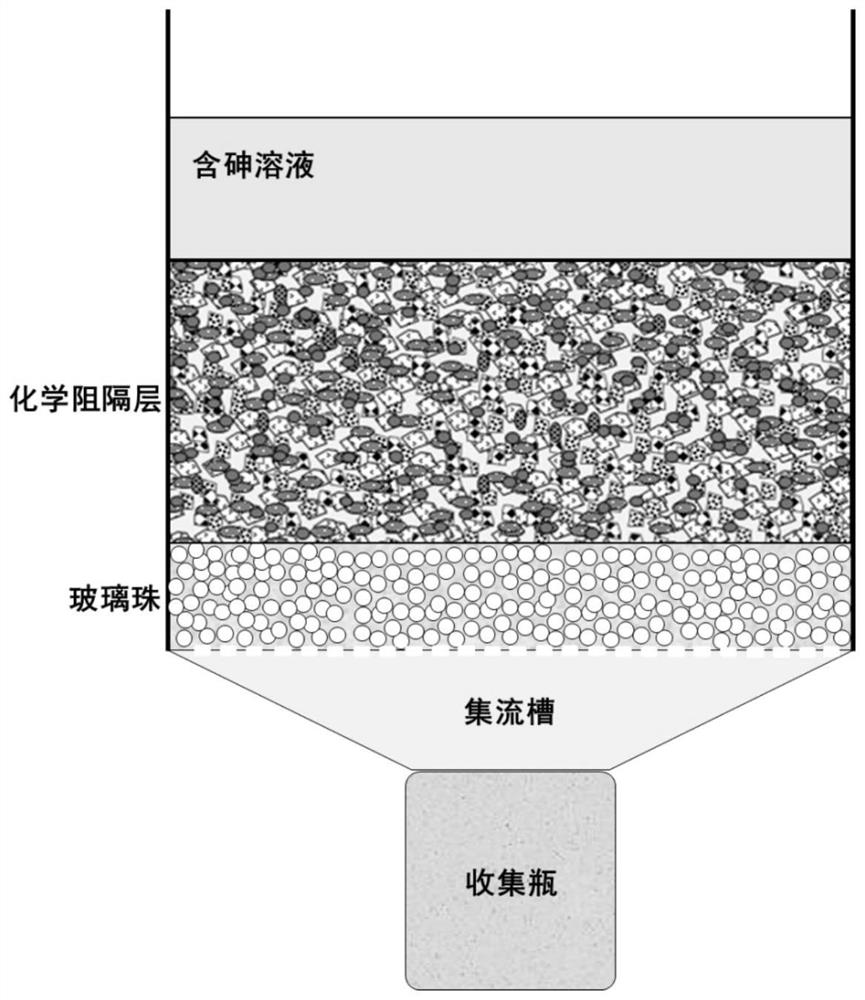

[0070] Example 2 Chemical barrier layer used in pilot field barrier control of heavy metal arsenic-contaminated soil

[0071] According to the disposition result of the chemical barrier layer verified by the small test experiment in step 2) of embodiment 1, the sampling site of the polluted soil sample in the chemical barrier material matrix in the chemical barrier material matrix prepared in step 1) of embodiment 1 (a chemical industry in the north) A 5m long and 5m wide area in the factory polluted site) was selected to carry out the pilot test of contaminated soil isolation. During the construction process, the polluted target area was first cleared and excavated, and a flat-bottomed foundation pit with a length of 7m, a width of 7m and a depth of 800mm was excavated ( Figure 7 ), and then adopt the chemical barrier material prepared in step 1) of Example 1 as the chemical barrier layer, the thickness of the barrier layer is designed to be 0.5m, and the total amount of fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com