Full-compliant impact-overload-resistant dynamic mass compensation micro-positioning device

A dynamic mass, micro-positioning technology, used in maintenance and safety accessories, measuring/indicating equipment, metal processing equipment, etc., can solve problems such as limiting the working stroke of the micro-positioning motion platform, inability to take into account positioning accuracy, and system heating, etc. It does not affect the positioning accuracy and dynamic performance, the effect of simple structure and high motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

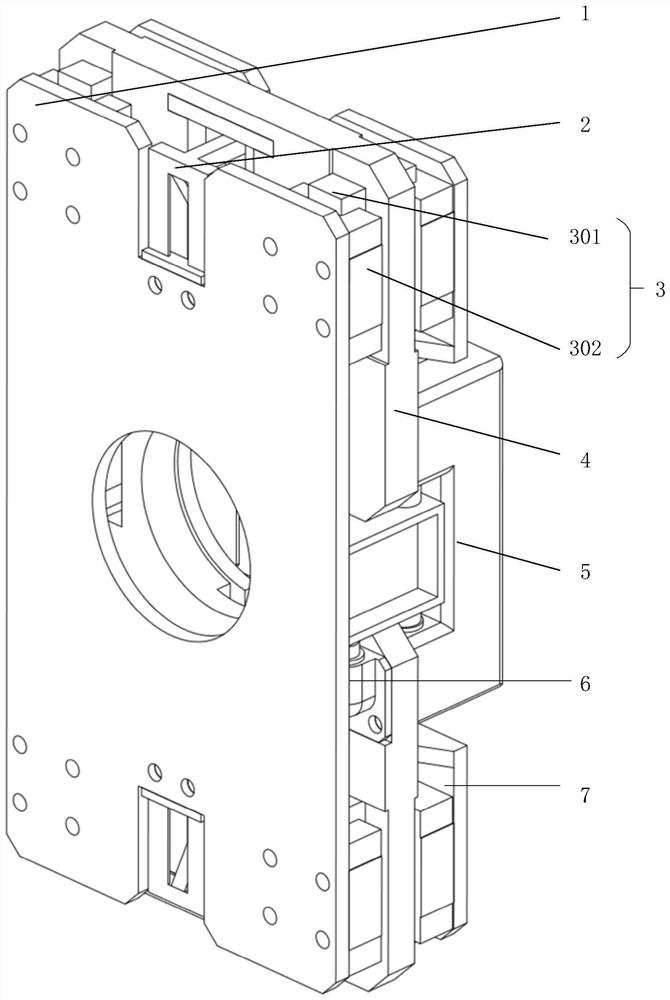

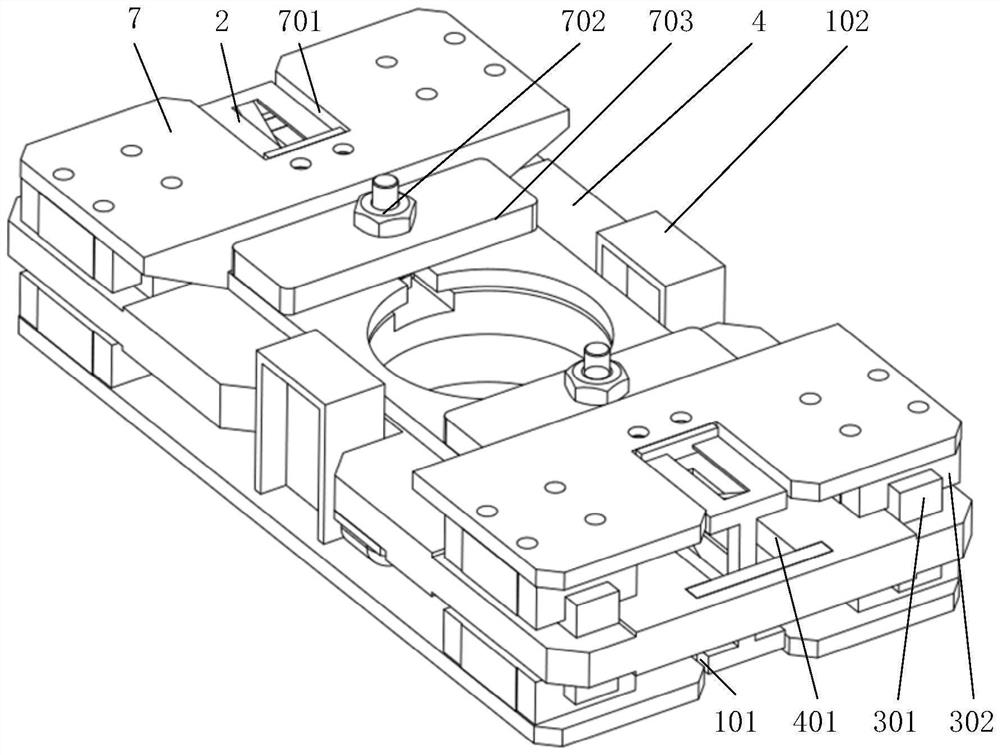

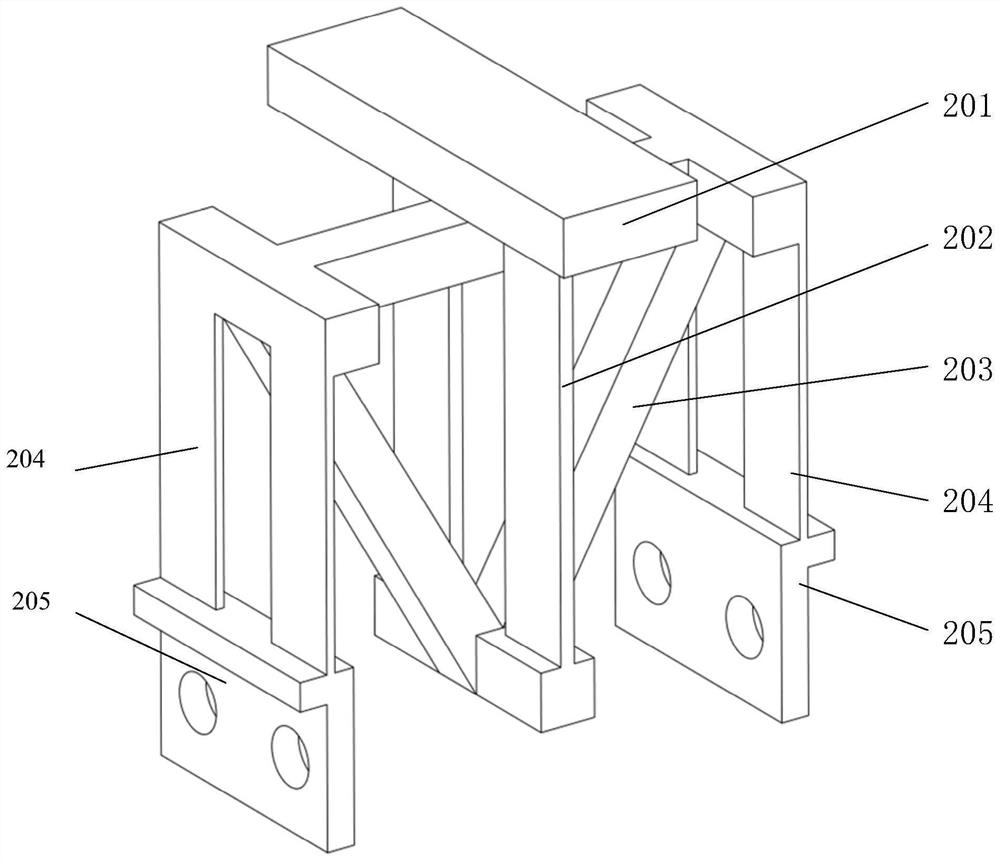

[0028] Such as figure 1 with figure 2 As shown, the fully compliant and shock-resistant dynamic mass compensation micro-positioning device of the present invention includes a compliant lever mechanism 2, a motion platform 1, a mass counterweight platform 7, a base 4, multiple sets of guide rail slider assemblies 3, a driver 5 and The sensor 6; the rigid fulcrum crossbeam 201 of the compliant lever mechanism 2 is fixed on the base 4, and the motion platform 1 and the mass counterweight platform 7 pass through the multiple sets of guide rail slider assemblies 3 and the base 4 respectively. Both sides are connected, and translational freedom in one direction is reserved; the left and right ends of the compliant lever mechanism 2 are fixedly connected with the motion platform 1 and the mass counterweight platform 7 respectively, and are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com