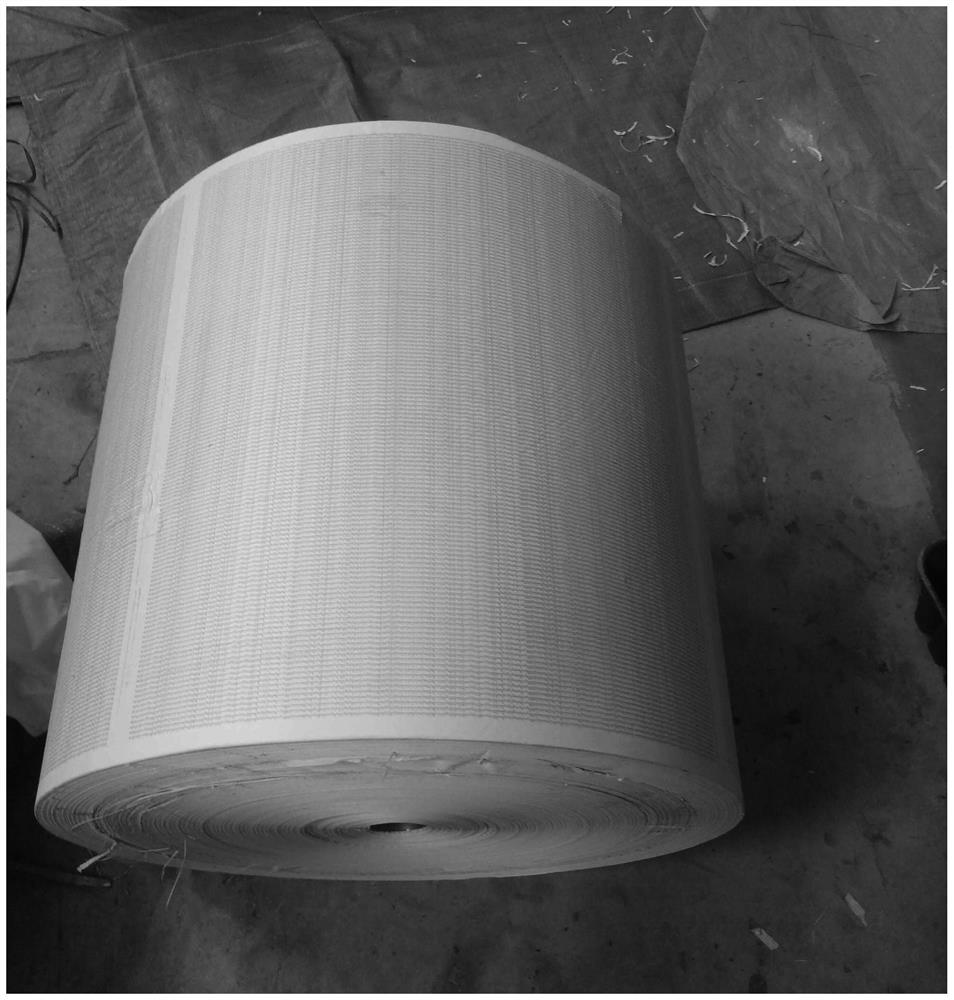

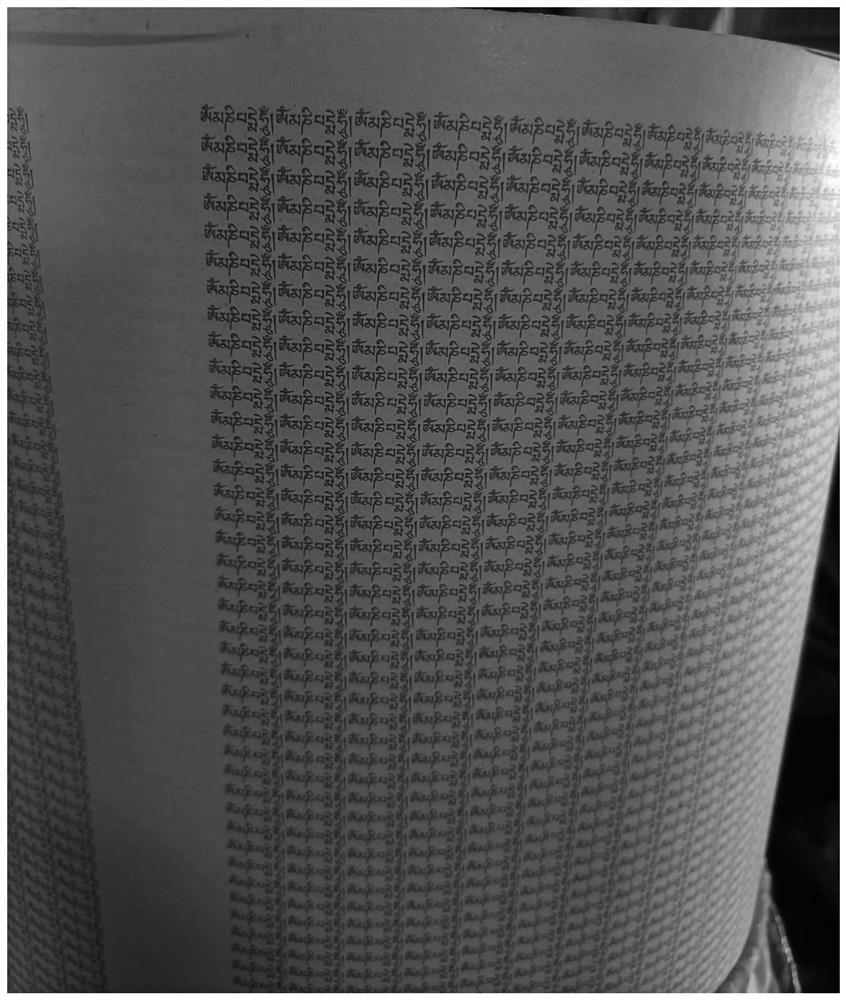

Printing and rolling integrated process

An integrated and crafted technology, which is applied in the printing field, can solve the problems of easy discoloration of scriptures, irregular manual cutting, high production requirements, etc., and achieve the effect of prominent and clear scriptures, long storage time and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An integrated printing and rolling process of scriptures, comprising the following steps:

[0040] Pre-printing preparation: typeset scriptures according to requirements; weigh 30g of water, 18g of water-based acrylic emulsion, 15g of nano-aluminum hydroxide, 12g of sub-nanometer silicon powder, 4g of kaolin, 4g of hexanediol, 3g of modified hydrogenated castor oil, and lilac 2g, 2g of Albizia Julibrissin skin and 5g of carbon black, pulverize lilac and Albizia Juliensis skin into 200 mesh fine powder, mix each raw material evenly, pour in the ink cartridge of printing machine; Print paper is carried out flattening standby.

[0041] Printing: The paper is sent to the printing equipment for scripture printing. The printing roller in the printing equipment uses an anilox roller made of ceramic material, which can make the printing clearer.

[0042] Drying: The paper printed with scriptures is dried quickly by ultraviolet drying to prevent the ink from scattering during wi...

Embodiment 2

[0047] An integrated printing and rolling process of scriptures, comprising the following steps:

[0048] Preparation before printing: typeset the scriptures according to requirements; weigh 40g of water, 20g of water-based acrylic emulsion, 12g of nano-aluminum hydroxide, 15g of sub-nano silicon powder, 2g of kaolin, 1g of hexanediol, N-methyl polyurea 4g of pyrrolidone solution, 4g of lilac, 4g of lavender and 2g of everlasting yellow GG, crush the lilac and lavender into 150 mesh fine powder, mix each raw material evenly, pour it into the ink box of the printing machine; flatten the printing paper for later use .

[0049] Printing: The paper is sent to the printing equipment for scripture printing. The printing roller in the printing equipment uses an anilox roller made of ceramic material, which can make the printing clearer.

[0050] Drying: The paper printed with scriptures is dried quickly by ultraviolet drying to prevent the ink from scattering during winding.

[005...

Embodiment 3

[0054] An integrated printing and rolling process of scriptures, comprising the following steps:

[0055] Preparation before printing: typeset the scriptures according to the requirements; weigh 25g of water, 15g of water-based acrylic emulsion, 18g of nano-aluminum hydroxide, 8g of sub-nanometer silicon powder, 4g of kaolin, 5g of hexanediol, 1g of polyamide wax, 2g of cypress kernels, 1g of saffron, 1g of lavender and 8g of Jinguanghong C, crush the cypress kernels, saffron, and lavender into 100-mesh fine powder, mix each raw material evenly, pour it into the ink cartridge of the printing machine; flatten the printing paper for later use.

[0056] Printing: The paper is sent to the printing equipment for scripture printing. The printing roller in the printing equipment uses an anilox roller made of ceramic material, which can make the printing clearer.

[0057] Drying: The paper printed with scriptures is dried quickly by ultraviolet drying to prevent the ink from scatterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com