Sodium gold sulfite gold water as well as synthesis method and application thereof

A technology of gold sodium sulfite gold water and a synthesis method, which is applied to semiconductor devices, process efficiency improvement, circuits and other directions, can solve problems such as instability and color of gold sodium sulfite gold water, and achieves overcoming the influence of impurities and achieving good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The first aspect of the present invention provides a kind of synthetic method of sodium gold sulfite gold water, wherein, this synthetic method comprises:

[0022] Precipitating the chloroauric acid solution and ammonia water to obtain a bright orange-yellow precipitate product; wherein the concentration of ammonia water is 10-15 wt%, and the terminal pH of the precipitate product is 7.2-8.5;

[0023] The precipitated product is washed and filtered to obtain a gold fulminate precipitate;

[0024] A slurry prepared by mixing the gold fulminate precipitate with water, then performing an initial reaction with sulfite on the slurry, and then adjusting the final pH of the obtained reaction product to be greater than 10 and not greater than 11 to obtain an alkaline product;

[0025] The alkaline product is reacted again to obtain a gold plating solution free of trivalent gold ions.

[0026] The synthesis method provided by the present invention improves the conditions for pr...

Embodiment 1

[0052] Gold dissolution: Put 20g of gold flakes into a beaker, add aqua regia and heat until all the gold is dissolved;

[0053] Nitrate removal with hydrochloric acid: Concentrate the gold solution, and add concentrated hydrochloric acid dropwise until no yellow nitrogen oxides escape. After the removal of nitrification, dilute with pure water to 200mL to obtain a chloroauric acid solution with a concentration of 100g / L;

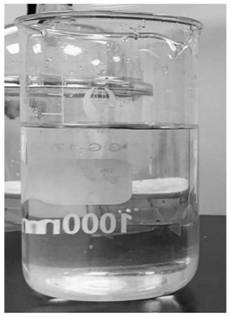

[0054] Ammonia precipitation: dilute concentrated ammonia with pure water (the concentration of ammonia water is 12.5wt%) and then add it to the chloroauric acid solution for precipitation reaction. The temperature of the precipitation reaction is 60°C. The precipitation is gradually formed and the stirring is continued until the final pH value of the precipitated product was 7.9, and a bright orange-yellow precipitated product (such as Figure 1a shown);

[0055] Cleaning and filtering: transfer the precipitated product to a Buchner funnel, stir and wash t...

Embodiment 2

[0059] Gold dissolution: Put 20g of gold flakes into a beaker, add aqua regia and heat until all the gold is dissolved;

[0060] Nitrate removal with hydrochloric acid: Concentrate the gold solution to 100 g / L, and add concentrated hydrochloric acid dropwise until no yellow nitrogen oxides escape. After the removal of nitric acid, dilute to 200 mL with pure water to obtain a chloroauric acid solution with a concentration of 100 g / L;

[0061] Ammonia precipitation: Dilute concentrated ammonia water with pure water (the concentration of ammonia water is 14wt%) and then add it to the chloroauric acid solution for precipitation reaction. The temperature of the precipitation reaction is 55° C., and the precipitation is gradually generated and the stirring is continued until the final pH value of the precipitated product is 8.1, a bright orange-yellow precipitated product (with Figure 1a Similar results, not shown);

[0062] Cleaning and filtering: transfer the precipitated product t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com