Copper wire rolling equipment with uniform output function

A rolling equipment and copper wire technology, applied in the field of uniform output copper wire rolling equipment, can solve the problems of copper wire thickness difference, deformation or extrusion degree deviation, reduce the use value of copper wire rolling equipment, etc., and achieve The effect of ensuring uniformity, facilitating rolling operations, and improving use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

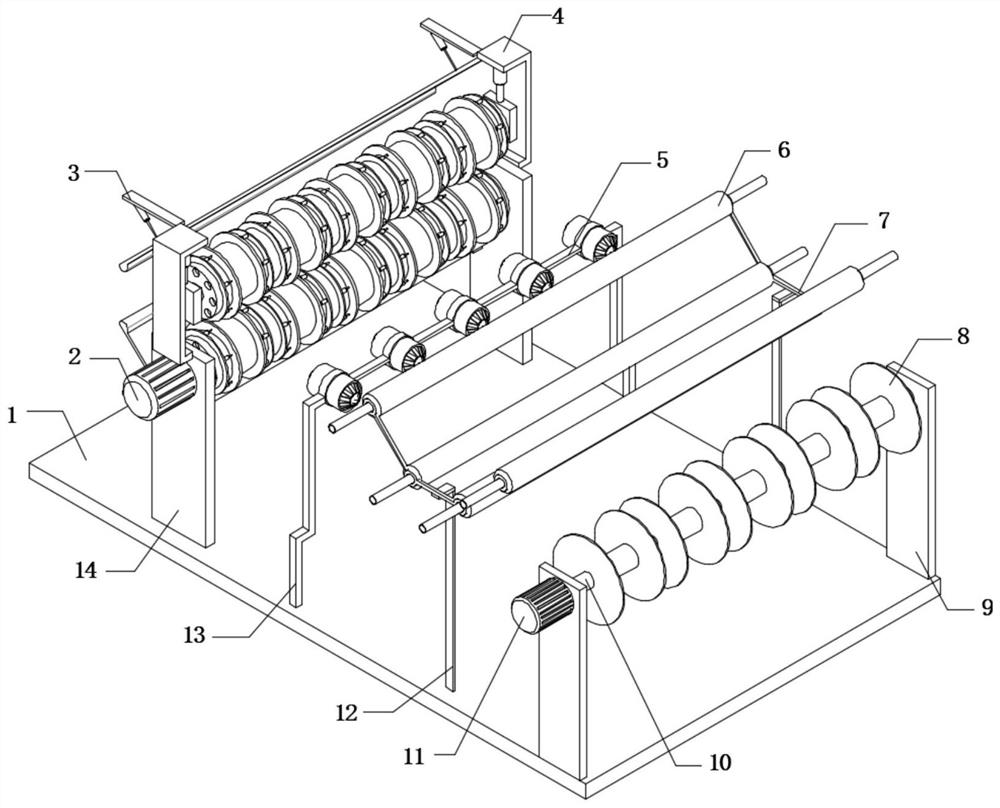

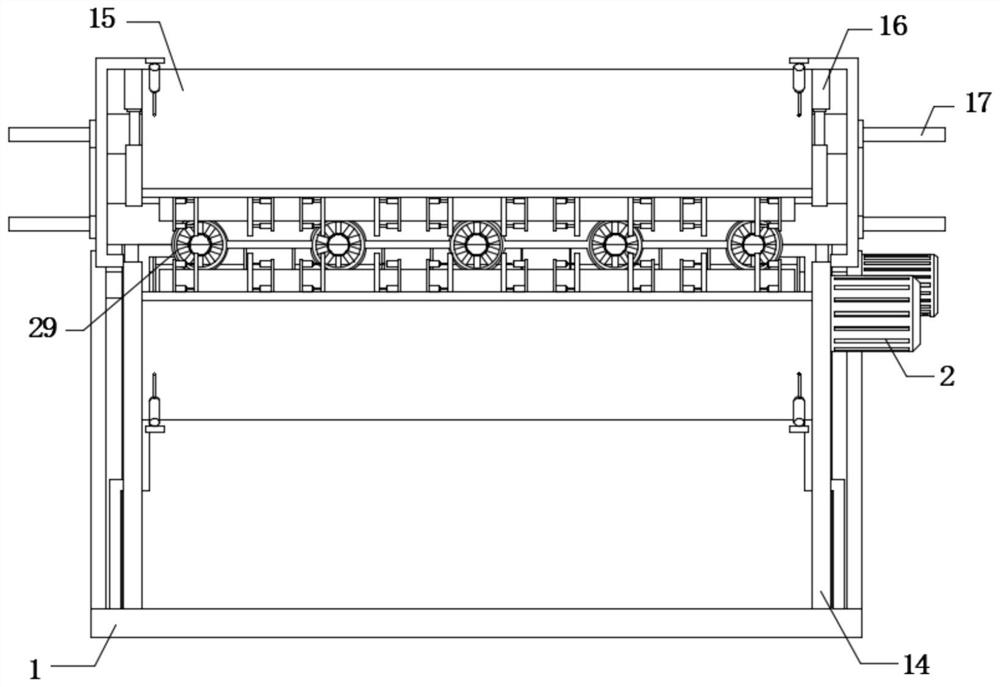

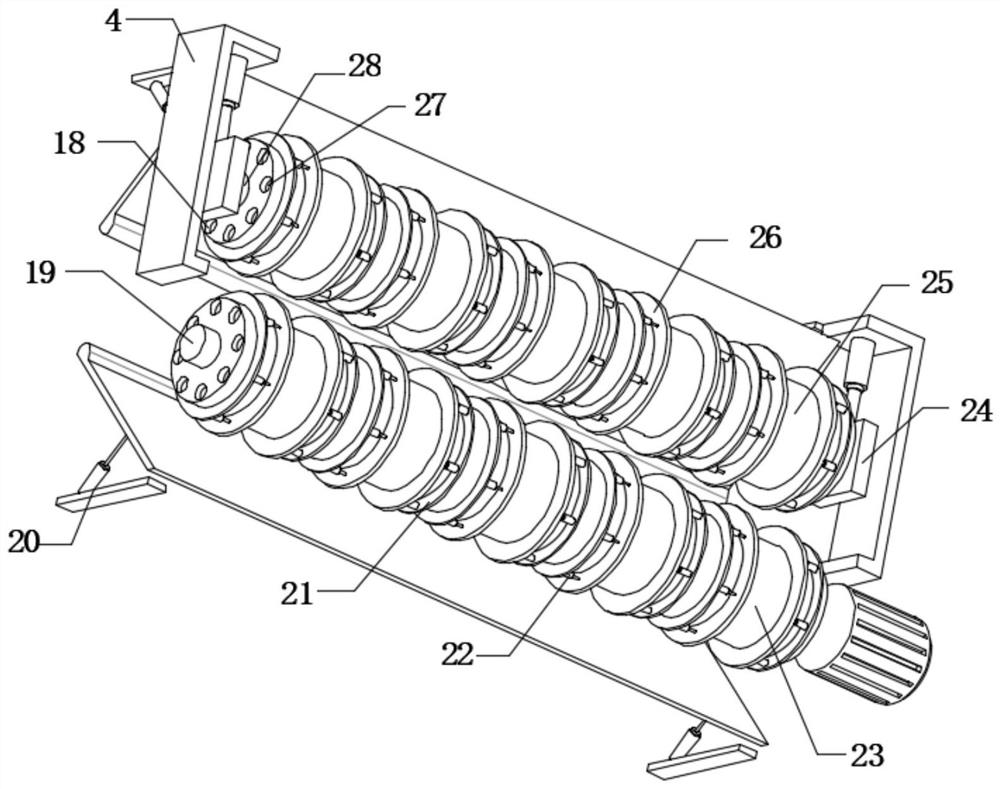

[0024] refer to Figure 1-4 , a copper wire rolling equipment with uniform output, comprising a bottom plate 1, a No. 1 rolling roll 23 and a No. 2 rolling roll 25, the top outer wall of the bottom plate 1 is fixedly connected with two support frames 13, and the two support frames 13 The outer wall of the tube holder 5 is fixedly connected with the same tube holder 5, the inner wall of the tube holder 5 is equidistantly fixedly connected with the through-tube 29, and the inner wall near the opening end of each through-tube 29 is fixedly connected with the inner sheet 30 at an equal distance, and the inner sheet 30 is distributed in a ring Inside the barrel 29, two sh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap