Preparation method of novel ferrocene derivative anion exchange membrane

A ferrocene derivative and anion exchange membrane technology, applied in the field of preparation of novel ferrocene derivative anion exchange membrane, can solve the problems of harsh preparation conditions, unsuitable for large-scale industrial application, high price, etc. The effect of short time, improving ionic conductivity, and improving ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

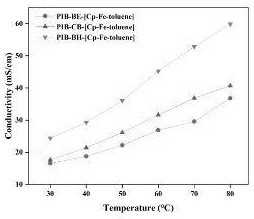

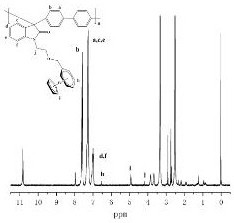

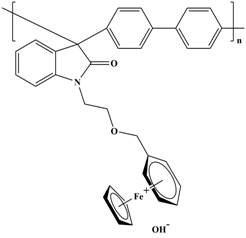

[0030] Embodiment 1, the method for preparing PIB-BE-[Cp-Fe-toluene] anion exchange membrane

[0031] (1) Weigh 1g of PIB and dissolve it in 20ml of N,N-dimethylformamide with stirring at 40°C to obtain a light yellow transparent solution;

[0032] (2) Add anhydrous potassium carbonate to the above solution with the molar ratio of PIB:K2CO3=1:2, and add BE solution to the above solution with the molar ratio of PIB:BE=1:3 , kept stirring at 65°C for 48 hours, then poured into a large amount of acetone to precipitate, washed several times, and dried in a vacuum oven at 40°C to obtain PIB-BE as a white solid;

[0033] (3) Weigh 0.25g of PIB-BE and dissolve it in 5ml of N,N-dimethylformamide with stirring at 40°C to obtain a light yellow transparent solution;

[0034] (4) Take the molar ratio as PIB-BE:NaH:TBAB=1:1:0.1, add NaH and TBAB to the above solution at 0°C, and take the molar ratio as PIB-BE:Br-[Cp- Fe-toluene]PF6=1:3 ratio, add Br-[Cp-Fe-toluene]PF6 solution to the abo...

Embodiment 2

[0038] Embodiment 2, the method for preparing PIB-CB-[Cp-Fe-toluene] anion exchange membrane

[0039] (1) Weigh 1g of PIB and dissolve it in 20ml of N,N-dimethylformamide with stirring at 40°C to obtain a light yellow transparent solution;

[0040] (2) With the molar ratio of PIB:K2CO3=1:2, add anhydrous potassium carbonate to the above solution, and with the molar ratio of PIB:CB=1:3, add CB solution to the above solution , kept stirring at 80°C for 48 hours, then poured into a large amount of acetone to precipitate, washed several times, and dried in a vacuum oven at 40°C to obtain a white solid;

[0041] (3) Weigh 0.25g of PIB-CB and dissolve it in 5ml of N,N-dimethylformamide with stirring at 40°C to obtain a colorless light yellow transparent solution;

[0042] (4) The molar ratio is PIB-CB:NaH:TBAB=1:1:0.1, add NaH and TBAB to the above solution at 0°C, and the molar ratio is PIB-CB:Br-[Cp- Fe-toluene]PF6=1:3 ratio, add Br-[Cp-Fe-toluene]PF6 solution to the above solut...

Embodiment 3

[0046] Embodiment 3, the method for preparing PIB-BH-[Cp-Fe-toluene] anion exchange membrane

[0047] (1) Weigh 1g of PIB and dissolve it in 20ml of N,N-dimethylformamide with stirring at 40°C to obtain a light yellow transparent solution;

[0048] (2) With the molar ratio of PIB:K2CO3=1:2, add anhydrous potassium carbonate to the above solution, and with the molar ratio of PIB:BH=1:3, add BE solution to the above solution , kept stirring at 65°C for 48 hours, then poured into a large amount of acetone to precipitate, washed several times, and dried in a vacuum oven at 40°C to obtain a white solid;

[0049] (3) Weigh 0.25g of PIB-BH and dissolve it in 5ml of N,N-dimethylformamide with stirring at 40°C to obtain a light yellow transparent solution;

[0050] (4) The molar ratio is PIB-BH:NaH:TBAB=1:1:0.1, add NaH and TBAB to the above solution at 0°C, and the molar ratio is PIB-BH:Br-[Cp- Fe-toluene]PF6=1:3 ratio, add Br-[Cp-Fe-toluene]PF6 solution to the above solution, stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com