Polyimide/polyurethane aerogel film air filtering material as well as preparation and application thereof

An air filter material and polyimide technology, which is applied in the field of air filter material preparation, can solve the problems of poor filtering stability, large diameter and pore size, increased piezoresistance, etc., and achieves good application prospects, good mechanical properties, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

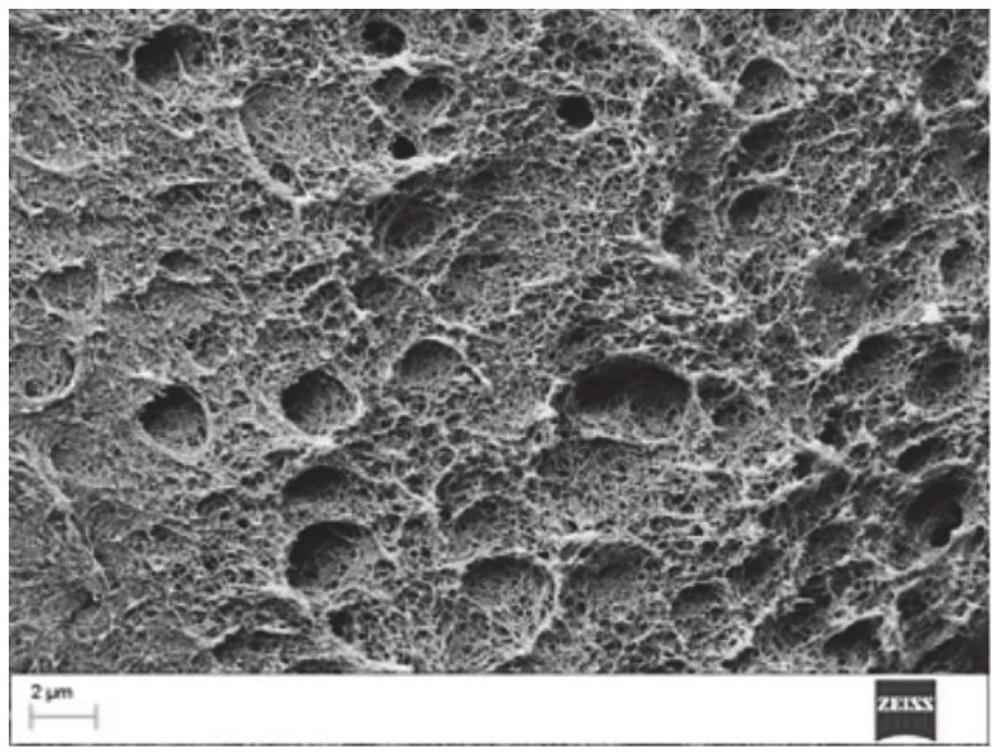

[0023] In view of this, in a kind of embodiment of the present invention, a kind of preparation method of PI / TPU airgel film is provided, comprises the steps:

[0024] S1: Use diamine and dianhydride as the precursor to react, add dehydrating agent and catalyst, add TPU and crosslinking agent, select reducing solvent, and prepare PI / TPU wet gel in square glass mold by sol-gel method.

[0025] S2: The wet gel was subjected to CO after aging 2 Supercritical drying to obtain PI / TPU composite airgel film.

[0026] in,

[0027] The diamine and dianhydride used in step S1 are respectively 4,4-diaminodiphenyl ether (ODA) and biphenyltetracarboxylic dianhydride (BPDA);

[0028] The cross-linking agent used in step S1 is 1,3,5-benzenetricarboxylic acid chloride (BTC);

[0029] The reducing solvent used in step S1 is N-methylpyrrolidone;

[0030] The square glass mold used in step S1 has a side length of 20 cm and a height of 2.5 cm.

[0031] The aging condition in step S2 is:

[...

Embodiment 1

[0040] 1) Preparation of PI / TPU airgel film

[0041] Under stirring conditions, dissolve 0.6323g of ODA in 15ml of NMP, put it into an ice-water bath after completely dissolving, add 0.9585g of BPDA, and obtain solution A after it is completely dissolved, and dissolve 0.5g of TPU in 5ml of NMP to obtain solution B, Dissolve 0.0143g of BTC in 3.2ml of NMP to obtain solution C, add 2.46ml of acetic anhydride and 2.1ml of pyridine to solution A, then add solution B and solution C to solution A in turn, stir for about 5 minutes and pour into a square glass mold , shake the mold to cover it evenly, seal it with plastic wrap, and get PI / TPU wet gel in about ten minutes.

[0042] After an interval of eight hours, pour aging solution 1 (25% ethanol + 75% NMP), and after one day of solvent replacement, pour out aging solution 1, pour aging solution 2 (25% NMP + 75% ethanol), and pour it out after one day Pour aging solution 2 into aging solution 3 (ethanol), and change the ethanol onc...

Embodiment 2

[0046] 1) Preparation of PI / TPU airgel film

[0047]Under stirring conditions, dissolve 0.843g of ODA in 15ml of NMP, put it into an ice-water bath after completely dissolving, add 1.278g of BPDA, and obtain solution A after it is completely dissolved, and dissolve 0.212g of TPU in 5ml of NMP to obtain solution B, Dissolve 0.019g of BTC in 4.269ml of NMP to obtain solution C, add 3.28ml of acetic anhydride and 2.8ml of pyridine to solution A, then add solution B and solution C to solution A in turn, stir for about 5 minutes and pour into a square glass mold , shake the mold to cover it evenly, seal it with plastic wrap, and get PI / TPU wet gel in about ten minutes.

[0048] After an interval of eight hours, pour aging solution 1 (25% ethanol + 75% NMP), and after one day of solvent replacement, pour out aging solution 1, pour aging solution 2 (25% NMP + 75% ethanol), and pour it out after one day Pour aging solution 2 into aging solution 3 (ethanol), and change the ethanol onc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoresistance | aaaaa | aaaaa |

| piezoresistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com