Low-temperature phase change cold storage material

A cold storage material and low-temperature phase change technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of phase stratification, stability to be verified, complex material ratio, etc., and achieve the effect of reversible phase change process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0015] The present invention may be more fully and better understood when considered in conjunction with the accompanying drawings. The drawings described here are used to provide a further understanding of the present invention, and the embodiments and their descriptions are used to explain the present invention, and do not constitute improper limitations to the present invention.

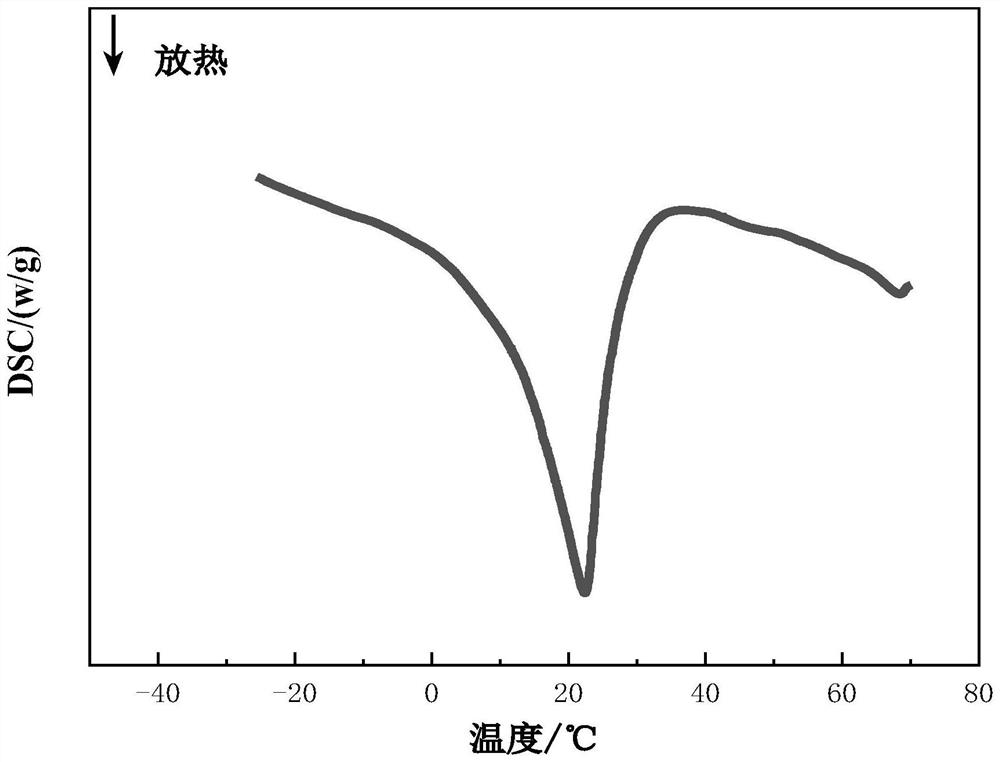

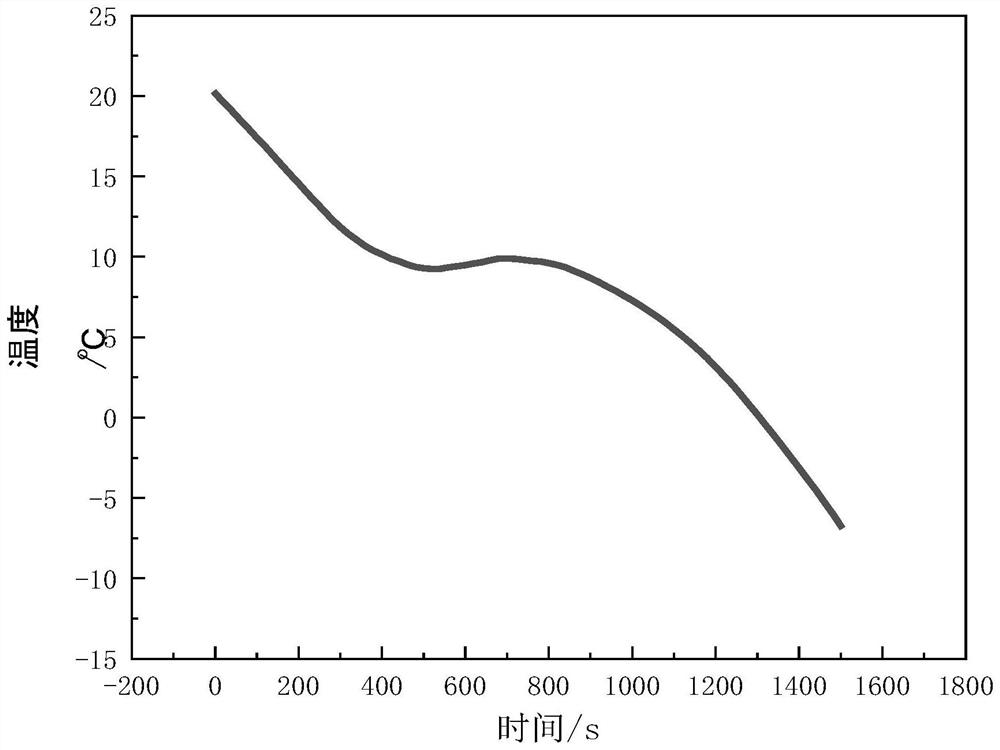

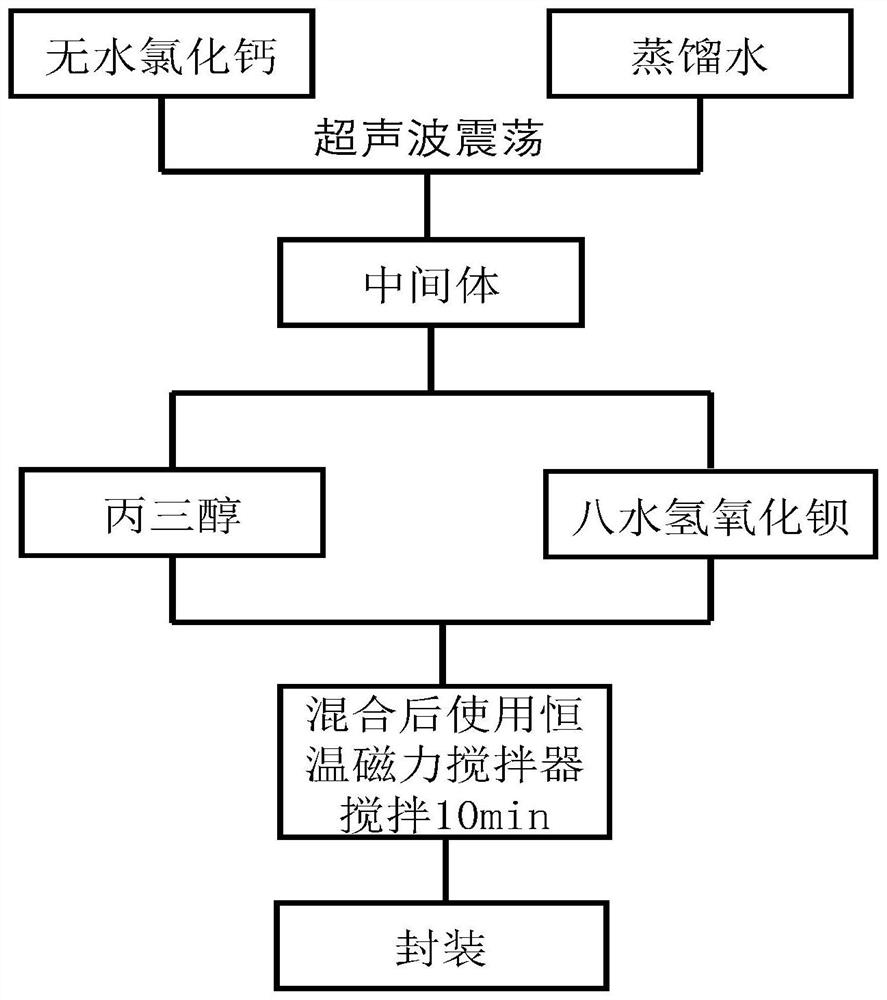

[0016] The invention proposes a low-temperature phase-change cold storage material, whose components include 42.65% anhydrous calcium chloride, 41.5% distilled water, 14.85% glycerol, and 1% octahydrate barium hydroxide. The preparation steps of the low temperature phase change cold storage material are as follows: image 3 , the method includes the following steps: when preparing the material, first weigh anhydrous calcium chloride and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com