Ceramic sand-like composite phase change material and preparation method thereof

A composite phase change material and ceramic sand particle technology are applied in the field of ceramic sand granular composite phase change material and its preparation, and achieve the effects of controlling high temperature diseases, simple preparation and maintaining ecological balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Embodiment 1: A ceramic sand granular composite phase change material in this embodiment is composed of 7-8 parts of ceramic sand and 2-3 parts of organic phase change material in parts by weight.

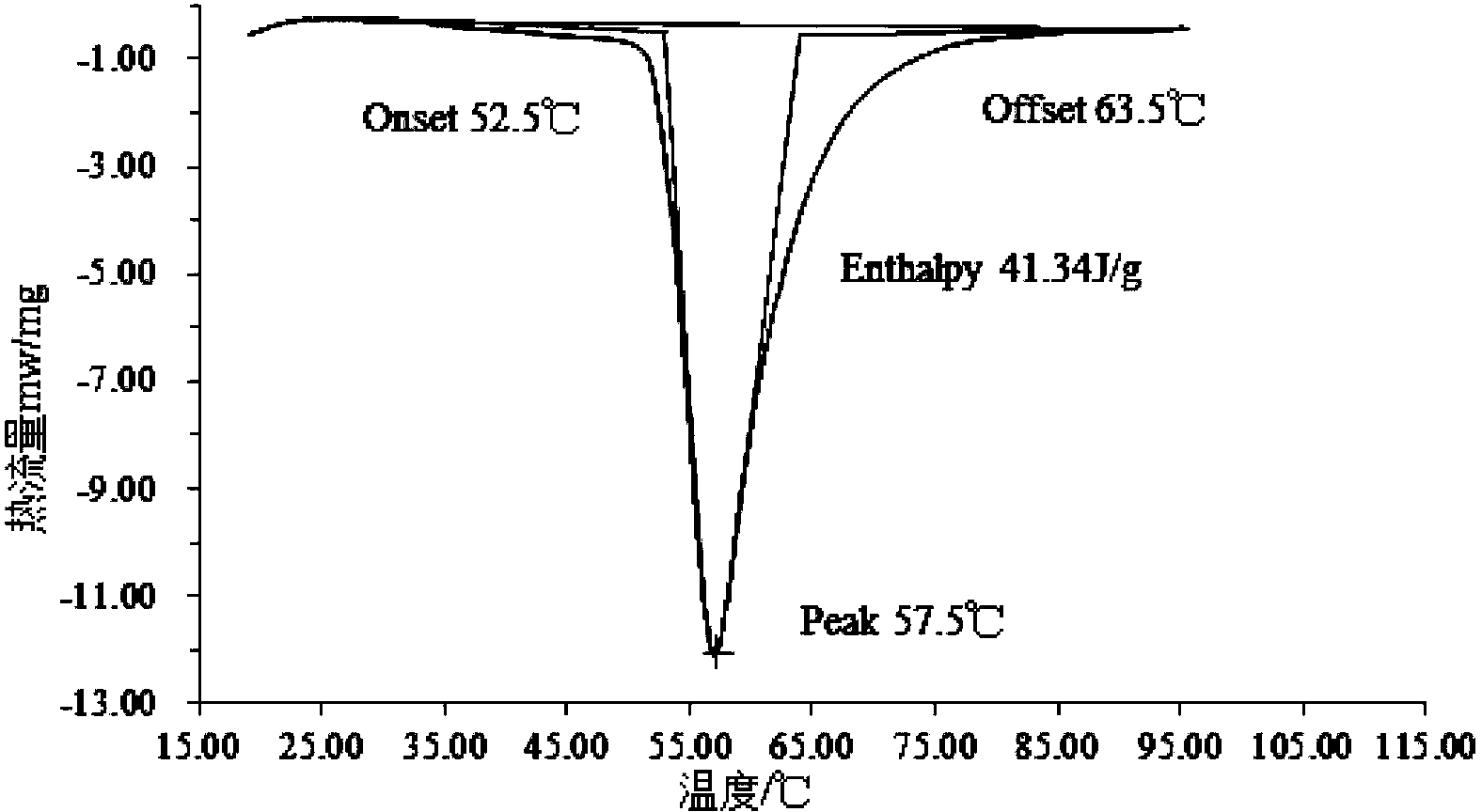

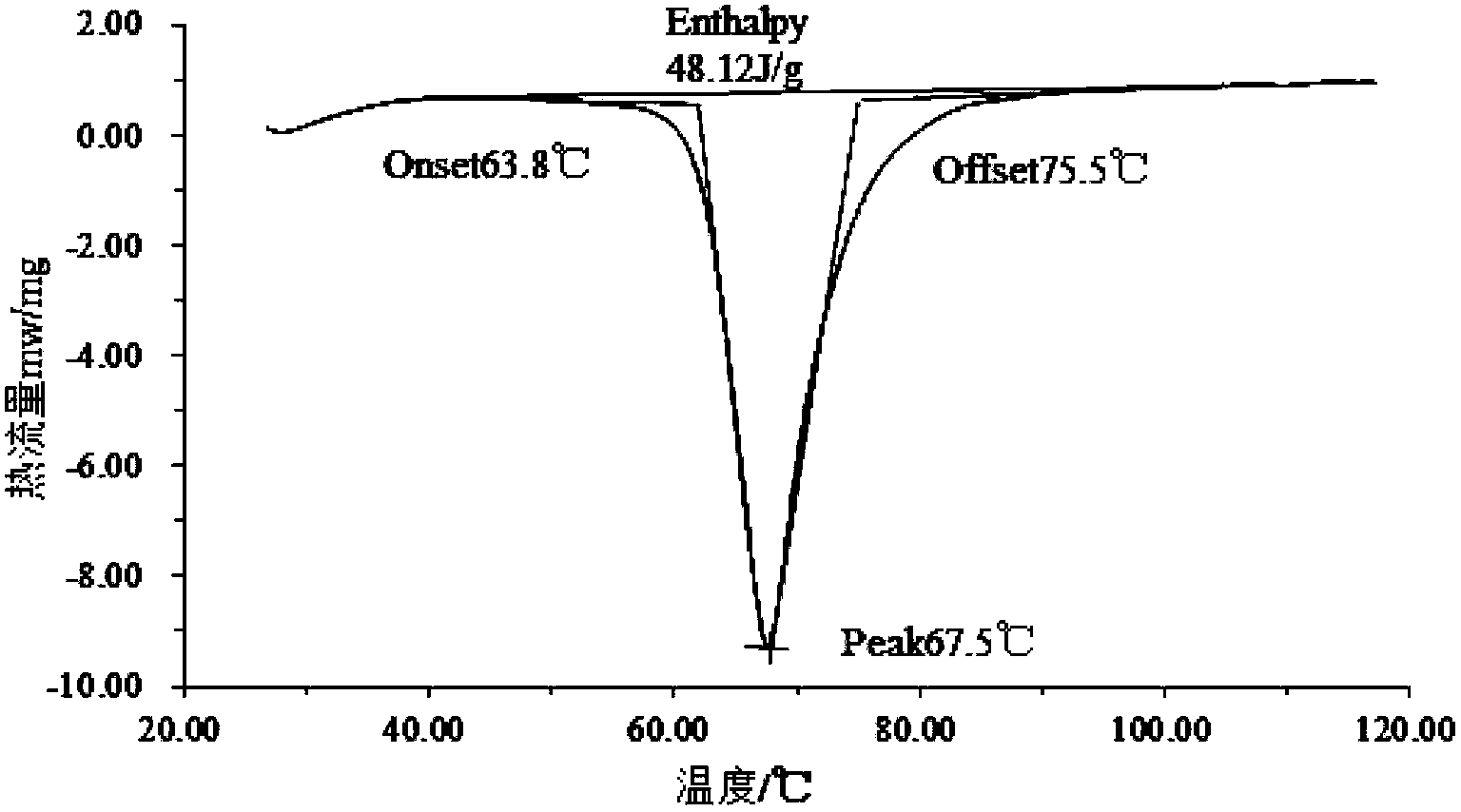

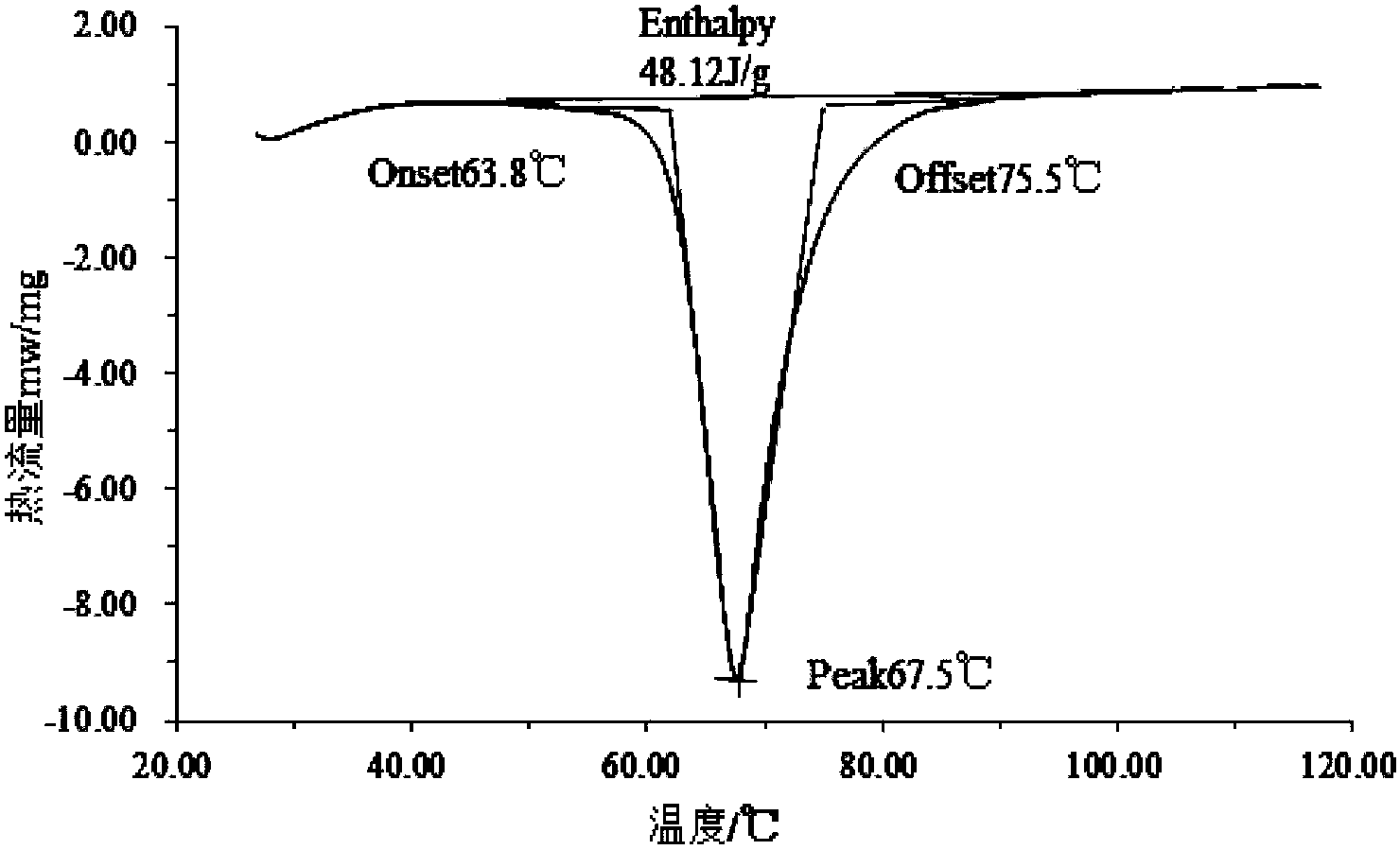

[0017] This embodiment utilizes the "peak-shifting and valley-eliminating" effect of phase change materials to adjust the temperature field of the asphalt pavement, reduce the possibility of high-temperature rutting, and achieve the purpose of effectively controlling high-temperature diseases of the asphalt pavement. At the same time, it has a certain control effect on the urban "heat island effect", reduces environmental pollution, and maintains ecological balance. The phase change material for pavement prepared by this embodiment has a reversible phase change process, a phase change temperature between 40°C and 75°C, and a phase change latent heat greater than 40kJ / kg. The material has a large phase change latent heat, non-toxic, non-corrosive, The preparation is simple an...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment is different from Embodiment 1 in that: the organic phase change material is myristic acid, PEG4000 or palmitic acid. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the preparation method of a kind of pottery sand granular composite phase change material of the present embodiment is carried out according to the following steps: 1. Weigh 7~8 parts of pottery sand and 2~3 parts of organic Phase change material; 2. Grinding, sieving, and washing the pottery sand for 3 to 5 times, and drying the washed pottery sand at 130°C~150°C for 2~3 hours; 3. Weighing step 1 The organic phase change material and the pottery sand dried in step 2 are mixed evenly according to the mass ratio of 3:7, put into a vacuum drying oven to evacuate to 0.09MPa, dry at 150°C for 2~3h, add volume Mineral powder with a fraction of 0.5%, mixed evenly, then dried in an oven at 150°C for 0.5~1h, cooled to room temperature, and passed through a 1.18mm or 0.6mm aggregate standard square hole sieve to obtain a composite material; Resin, acetone and ethylenediamine curing agent are mixed in a mass ratio of 1:0.15:0.25 and stirred evenly to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com