Device and method for preparing alcohol-free wine or strong wine

A high-alcohol and alcohol-penetrating technology, applied in the field of wine making, can solve the problems of easily oxidized components deteriorating and easily damaged, and achieve the effects of preventing easily oxidized components deteriorating, reliable process, and refreshing and natural taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

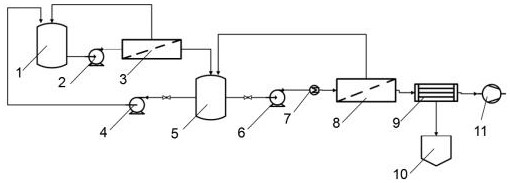

[0052] like figure 1 The shown device for preparing non-alcoholic wine or strong wine includes a raw material tank, a middle tank, a filter membrane module and an alcohol-permeable membrane module,

[0053] The raw material tank outlet is connected to the membrane filter assembly, the permeate side outlet of the filter membrane module is connected to the intermediate tank, and the retentate side outlet of the filter membrane module is connected to the raw material tank, and the filter membrane module includes a nano filter membrane or decolorizing membrane,

[0054] The outlet of the intermediate tank is respectively connected to the raw material tank and the alcohol-permeable membrane module through valves, and the outlet of the retentate side of the alcohol-permeable membrane module is connected to the intermediate tank.

[0055] The base film of the decolorization film is a composite base film of polyethyleneimine (PEI), N-methylpyrrolidone (NMP) and LiCl, and the active l...

Embodiment 1

[0066] The original wine with an alcohol content of 8° is separated through the filter membrane module, and the operating temperature is 0.5°C. After the separation is completed, a primary filter permeate with an alcohol content of 8.2° is formed on the permeate side, and a primary filter with an alcohol content of 7.2° is formed on the retentate side. Filter the retentate, the weight of once filtered permeate / original wine is 0.8. The primary filtered permeate is separated through the pervaporation and permeation membrane module. Alcohols and alcohol-soluble aroma components are preferentially permeated through the membrane. The permeate side obtains the first high-alcohol wine with an alcohol content of 35°, and the retentate side obtains alcohol with an alcohol content of 0.1° Once through the alcohol retentate. The primary alcohol retentate and the primary filter retentate are mixed and diluted to form low-alcohol wine with an alcohol content of 4°.

[0067] Then the low-...

Embodiment 2

[0070] The original wine with an alcohol content of 12.5° is separated through a filter membrane module, and the operating temperature is 10°C. After the separation is completed, a primary filter permeate with an alcohol content of 12.8° is formed on the permeate side, and a primary filter with an alcohol content of 10.8° is formed on the retentate side. The retentate is filtered, and the weight of the once-filtered permeate / original wine is 0.85. The primary filtered permeate is separated through the pervaporation and permeable alcohol membrane module. Alcohols and alcohol-soluble aroma components are preferentially permeated through the membrane. The permeate side obtains the first high-alcohol wine with an alcohol content of 40°, and the retentate side obtains alcohol with an alcohol content of 0.2° Once through the alcohol retentate. The primary alcohol retentate and the primary filter retentate are mixed and diluted to form low-alcohol wine with an alcohol content of 5°. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com